-

ProblemsParticles

Dust Emissions

Chemical Resistance

Product Life

Contamination -

Proposed EffectImproved Chemical Resistance

Improved Productivity(Improved Throughput)

Man-Hour Reduction

Long Service Life

Metal Contamination Control

Particle Control -

Product TypeOther

Customer's concerns and problems / Before

Our proposals and improvement effects / After

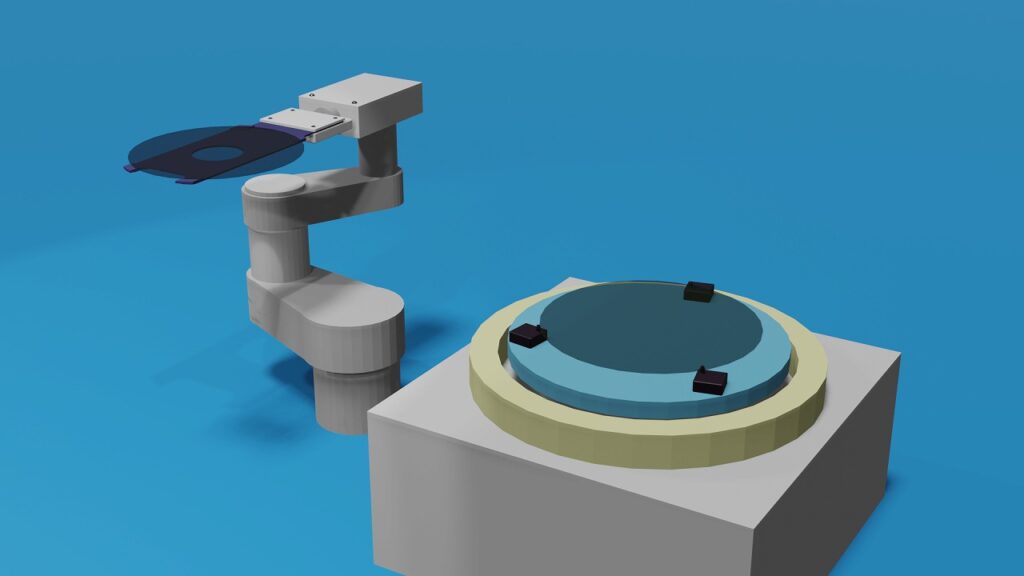

In response, the Ceramics Design Laboratory replaced plastic components with SiC (silicon carbide).

This has resulted in improved heat and chemical resistance, leading to longer service life.

In addition, special treatment of SiC has enabled us to deal with metal contamination and particles, both of which have been a challenge in previous SiC.

Point of the proposed example / Point

The point of this case is that the material change from resin to ceramics ensures the necessary heat resistance and chemical resistance.

In addition, metal contamination may become an issue with SiC, but defective parts can be reduced because measures are taken by special surface-treatment.

The Fine Ceramics Division of ASUZAC Corporation, which operates the Ceramics Design Laboratory, handles everything from material development and preparation to design and manufacture, as well as surface treatment, inspection, and cleaning.

We can also offer our own coating-technology for adding functionality to ceramics materials, as well as the selection of materials such as ceramics materials with high heat resistance and conductivity, and high-purity alumina and SiC that are highly pure and prevent contamination.

If you are considering changing materials from resin or metal to ceramics, or if you are having trouble with the heat resistance and strength of resin or the chemical resistance and corrosion resistance of metal, please feel free to contact us.

Integrated response from processing to development of ceramic materials !

Please feel free to contact us !

Business hours: 9:00-17:00 (closed on Saturdays, Sundays and Holidays)

.jpg)

.jpg)

Customers of semiconductor manufacturing equipment manufacturers asked us to develop ceramics materials by saying that we would like to change existing resin parts to materials with high heat resistance and chemical resistance.