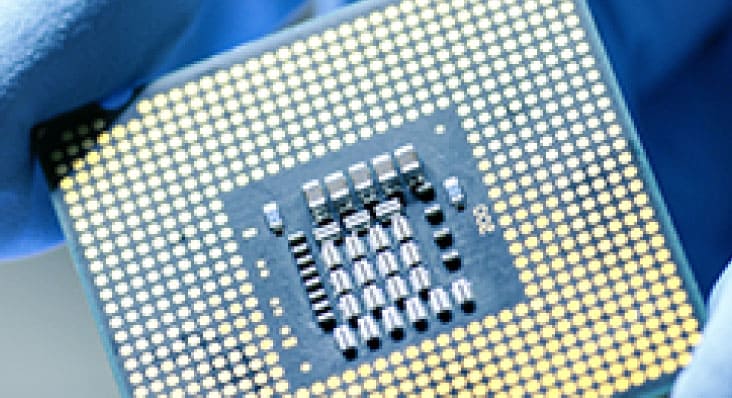

For fine ceramic products such as Transfer End Effector / Handling Arm and Porous Chuck

made in Japan

<Telephone quotations/inquiries>

TEL+81-26-248-1626

Business hours: 9:00-17:00

(closed on Saturdays, Sundays and Holidays)

Expertise in VA / VE proposals

backed by over 40 years of history

-

POINT 01

We offer solutions for cost reduction, functionality improvement, particle and static electricity countermeasures, and more.Our knowledge of our customers’ problems makes it possible for us to propose solutions.

In the manufacturing and transport processes of semiconductors and electronic components, these problems can occur

・Particle generation

・Reduction of yield due to contamination

・Wafer surface damage due to misalignment

・Outgas (outgassing)The Ceramics Design Laboratory is well aware of these industry-specific problems and the reasons behind them, and is actively proposing VA / VE techniques to solve each customer’s problem.

We can respond to customer needs by reducing costs, shortening lead times, reducing man-hours for parts replacement, and improving the functionality of the transfer End Effector / Handling Arm.

-

POINT 02

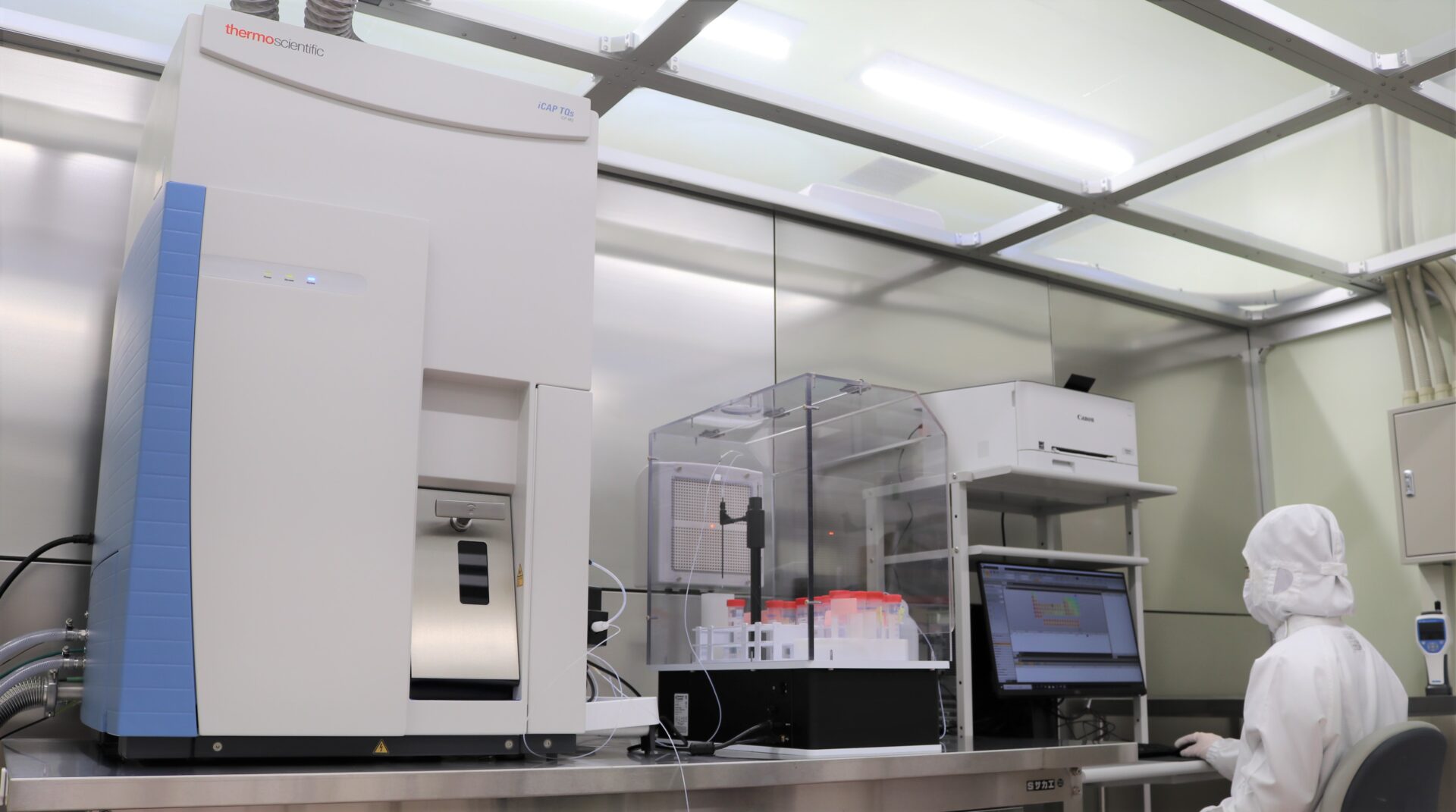

Reliable quality control system for industries that require high precision and quality

The Quality Control Division of the Fine Ceramics Division of ASUZAC Corporation, which operates the Ceramics Design Laboratory consists of the below three specialized units.

■ Quality Assurance Team

■ Inspection Team

■ Cleaning and Shipping TeamWe use the latest three-dimensional measuring instruments and high-performance analysis and inspection equipment to deliver products that satisfy the required accuracy and quality to our customers.

In the cleaning process, we use multilayer cleaning equipment to perform precision cleaning that can withstand the semiconductor manufacturing process.ISO9001・ISO14001 has also been obtained.

Integrated response from processing to development of ceramic materials !

Please feel free

to contact us !

Business hours: 9:00-17:00

(closed on Saturdays, Sundays and Holidays)

Four Reasons Why Ceramics Design Lab is Chosen

-

Integrated support from material development

to design and manufacture of ceramics -

Extensive delivery record for

semiconductor foundries,

electronic device manufacturers,

and equipment manufacturer -

Expertise in VA / VE proposals

backed by over 40 years of history -

Consignment services from prototyping

to mass production of one-off products

-

Frequently Asked Questions

Common questions from

the Ceramics Design Lab -

Available Material / Size / Product

Please see our wide range of

services -

Equipment owned

Our processing and

inspection facilities -

Company profile

Ceramics Design Lab is

operated by Asuzac Co., Ltd.

CONTACT

The quotation and inquiries are available by the telephone /FAX or the mail .

FAX. +81-26-251-2160