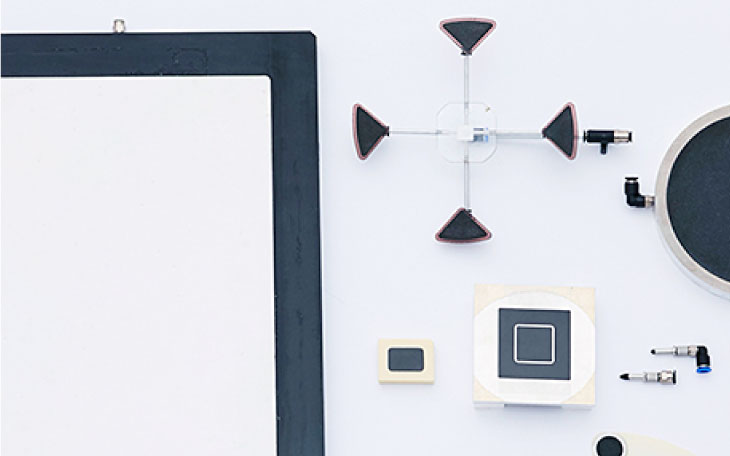

The demonstration machine for the Porous Chucks are available for rental. We have a lineup of products available for rent, please see the link below for details. Please contact us for a proposal based on your intended use.

>>Applications for a demonstration machine for the Porous Chuck are shown here.

外形120×80×厚み10mm-v1.jpg)