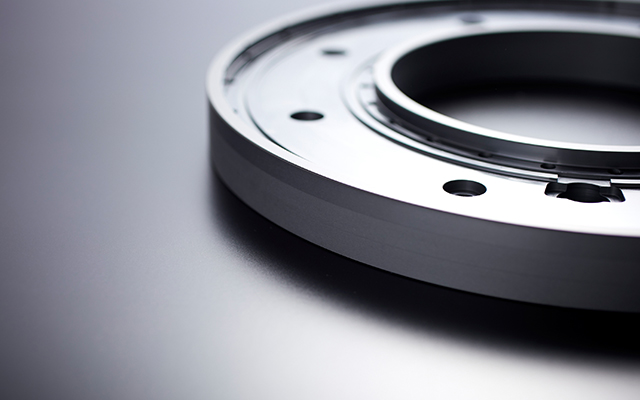

For fine ceramic products such as Transfer End Effector / Handling Arm and Porous Chuck

made in Japan

<Telephone quotations/inquiries>

TEL+81-26-248-1626

Business hours: 9:00-17:00

(closed on Saturdays, Sundays and Holidays)

Integrated support from material development

to design and manufacturing of ceramics !

-

POINT 01

Proposal of materials considering product usage and functionality precisely becausewe are responding from the development of ceramics materials

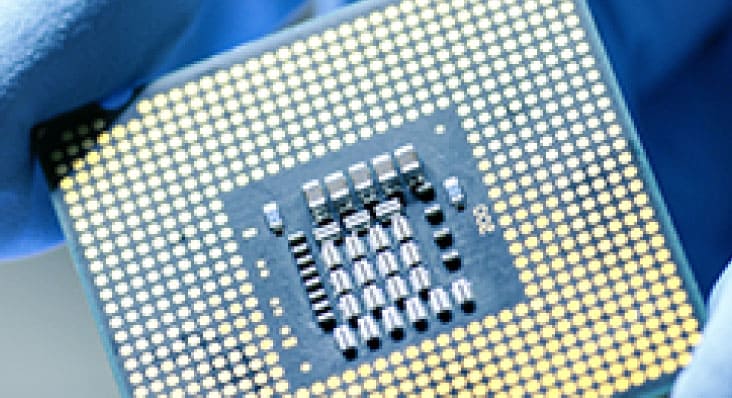

Our Ceramics Design Lab is familiar with the types and characteristics of fine ceramics materials,

as well as the usage environment and applications of products used in semiconductors,

electronic components, and other fields, enabling us to make optimal material proposals.

This enables us to propose the most suitable materials.We produce a wide variety of fine ceramics products such as alumina, silicon carbide (SiC), zirconia, porous ceramics, etc. “I want to process high-purity materials to prevent particle contamination.”

“We are looking for low-reflection ceramics, which are less likely to flare.”

“I don’t know which ceramic material to use.”

These are what we are often asked for advice on.Our in-house facilities and equipment for mixing and granulating raw materials, as well as for forming materials, enable us to develop special materials such as insulating ceramics, conductive ceramics, low-reflective Black Alumina, and high-purity ceramics, so that we are able to contribute to the solution of our customers’ issues.

-

POINT 02

Integrated manufacturer of Fine Ceramics

Our strengths are not limited to material procurement and material development.

We are a one-stop shop for everything from raw material preparation, shape design and design proposals, green machining and firing, post-firing machining, NC lathe machining, grinding, polishing, surface treatment and assembly, and pre-delivery inspection and evaluation. This is the reason why our customers have chosen us for many years.

This “Integrated Manufacturing System” is supported by our excellent engineers and quality control departments and a range of high-performance facilities.

Integrated response from processing to development of ceramic materials !

Please feel free

to contact us !

Business hours: 9:00-17:00

(closed on Saturdays, Sundays and Holidays)

Four Reasons Why Ceramics Design Lab is Chosen

-

Integrated support from material development

to design and manufacture of ceramics -

Extensive delivery record for

semiconductor foundries,

electronic device manufacturers,

and equipment manufacturer -

Expertise in VA / VE proposals

backed by over 40 years of history -

Consignment services from prototyping

to mass production of one-off products

-

Frequently Asked Questions

Common questions from

the Ceramics Design Lab -

Available Material / Size / Product

Please see our wide range of

services -

Equipment owned

Our processing and

inspection facilities -

Company profile

Ceramics Design Lab is

operated by Asuzac Co., Ltd.

CONTACT

The quotation and inquiries are available by the telephone /FAX or the mail .

FAX. +81-26-251-2160