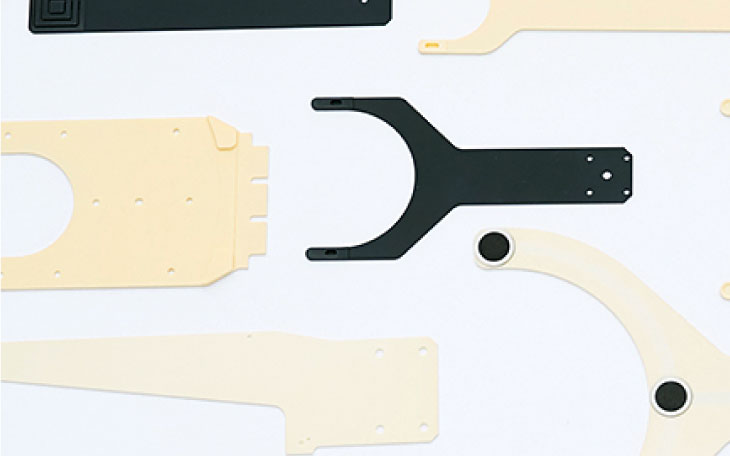

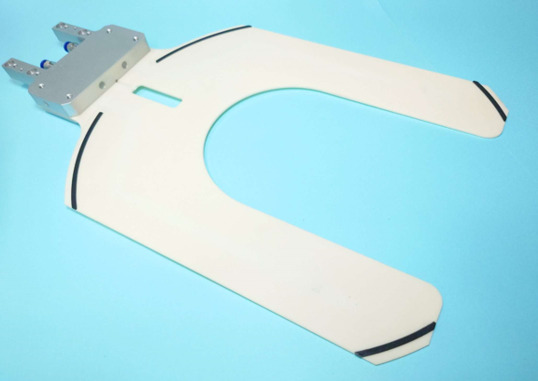

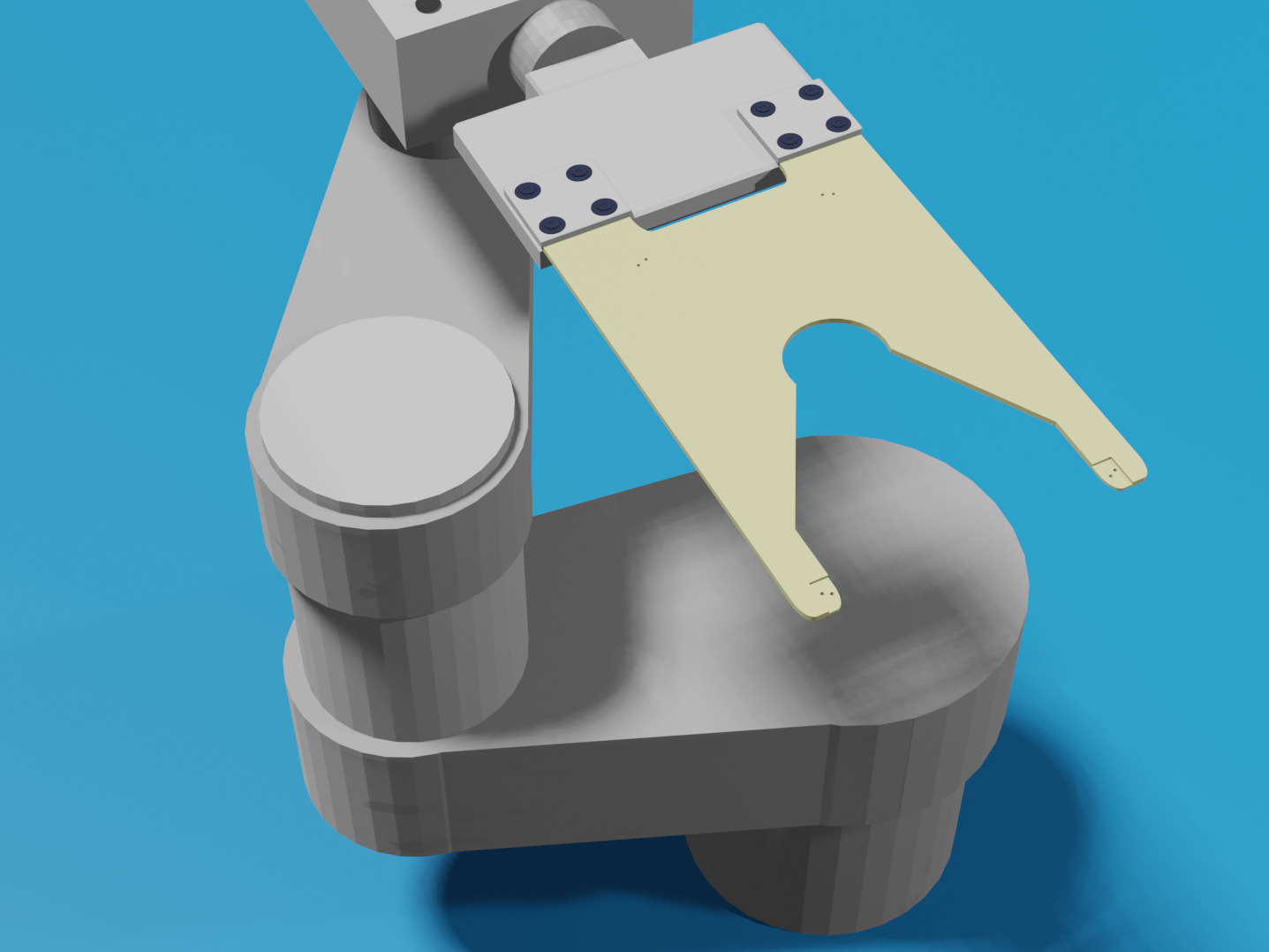

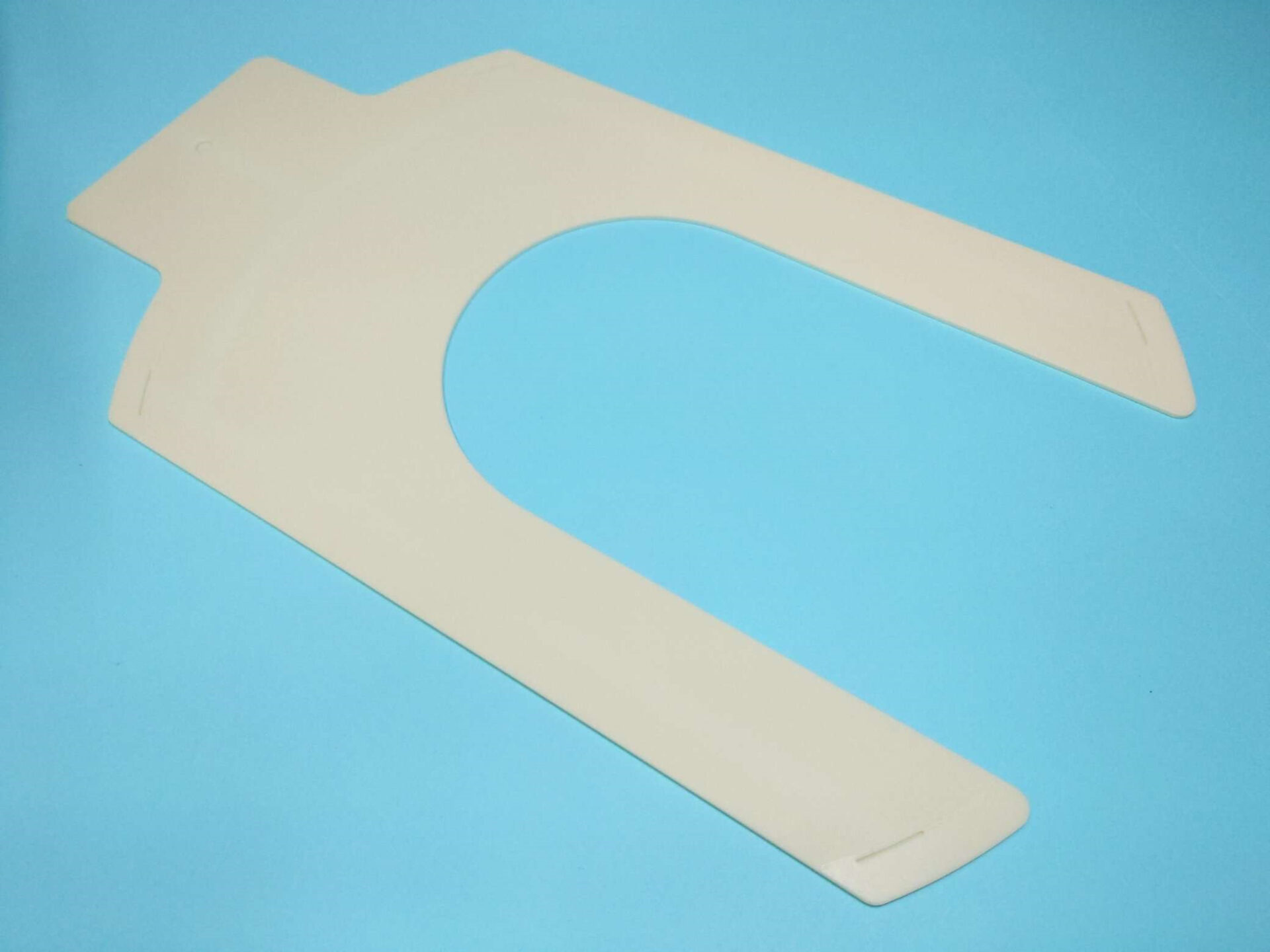

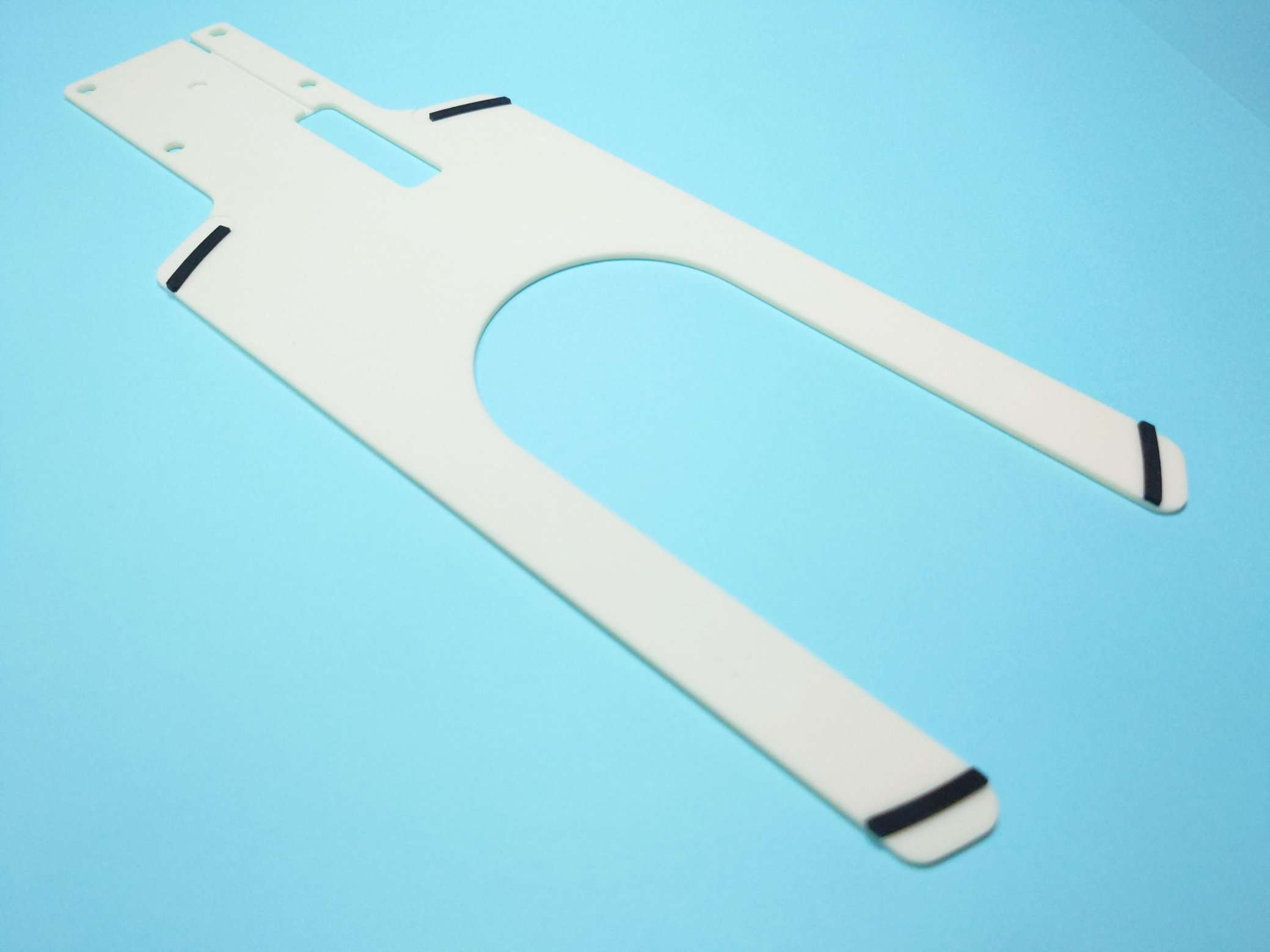

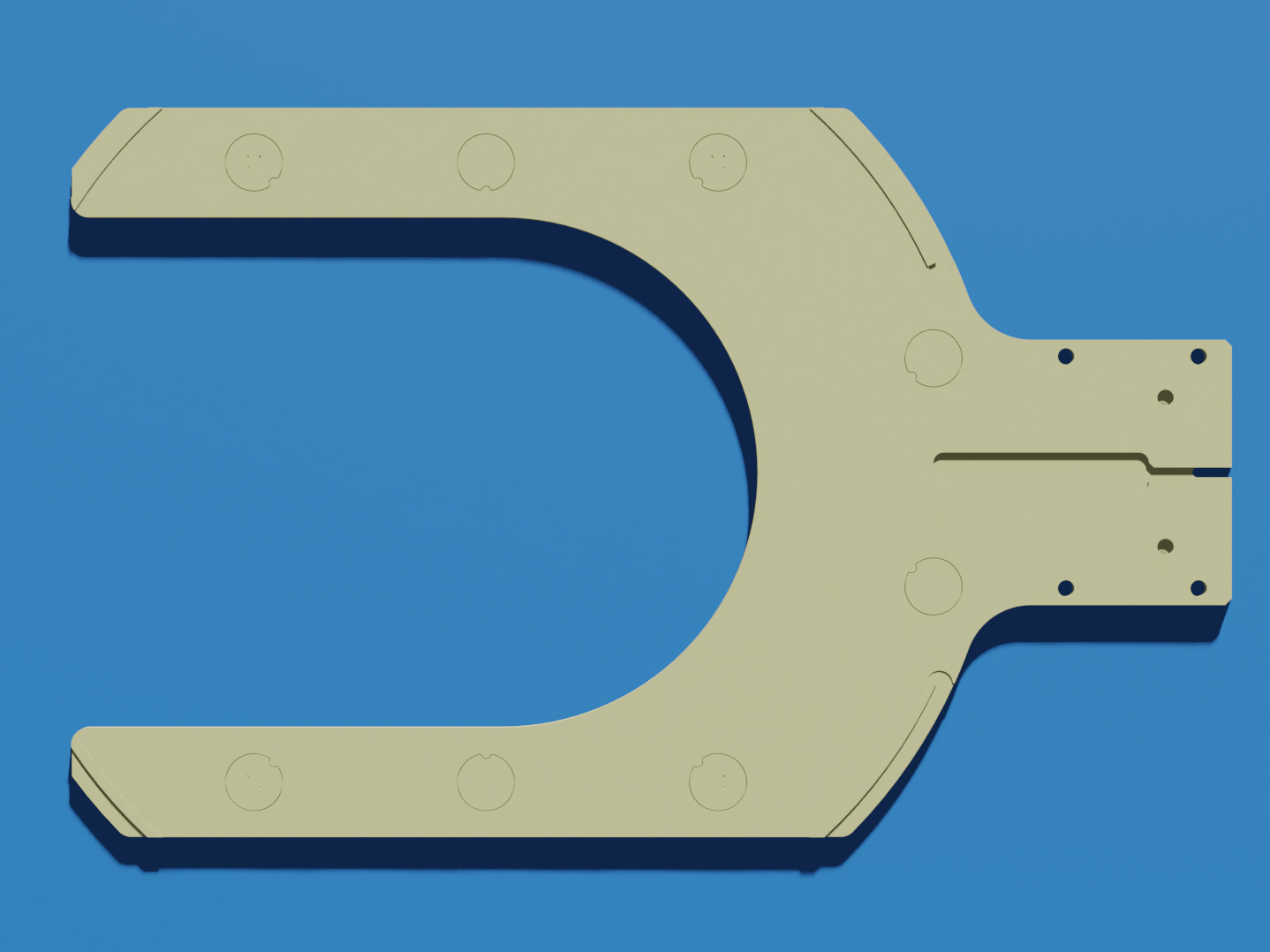

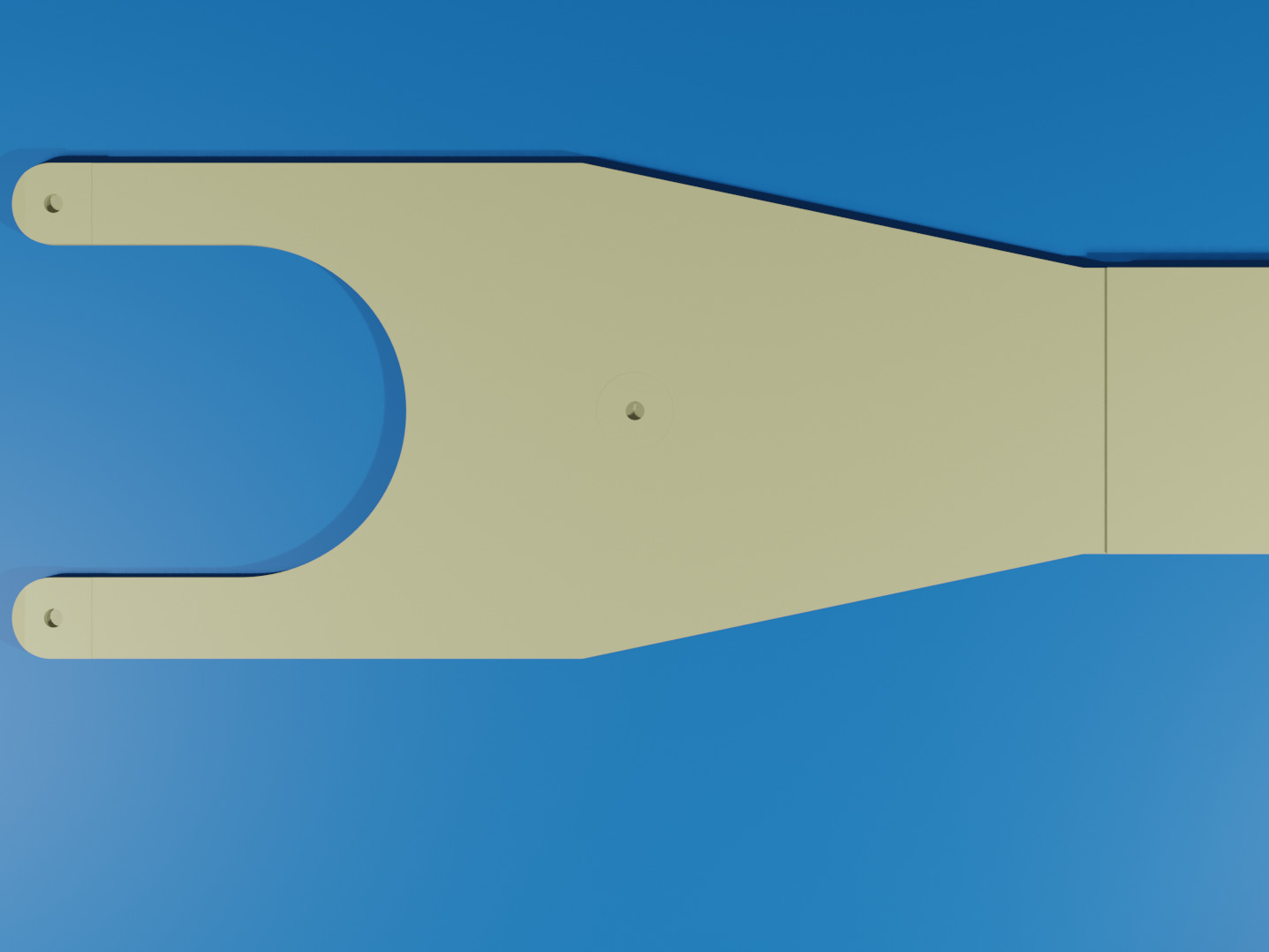

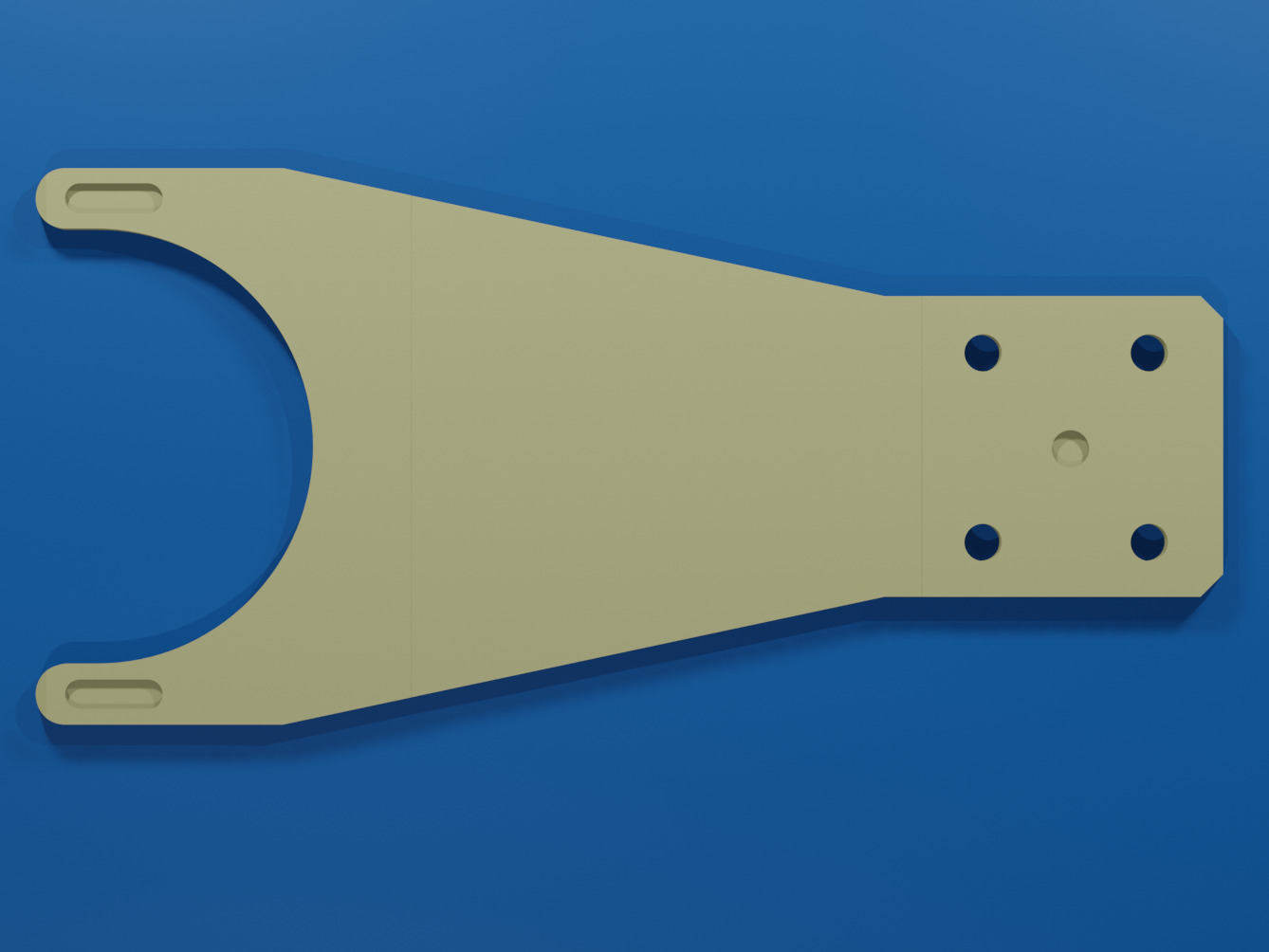

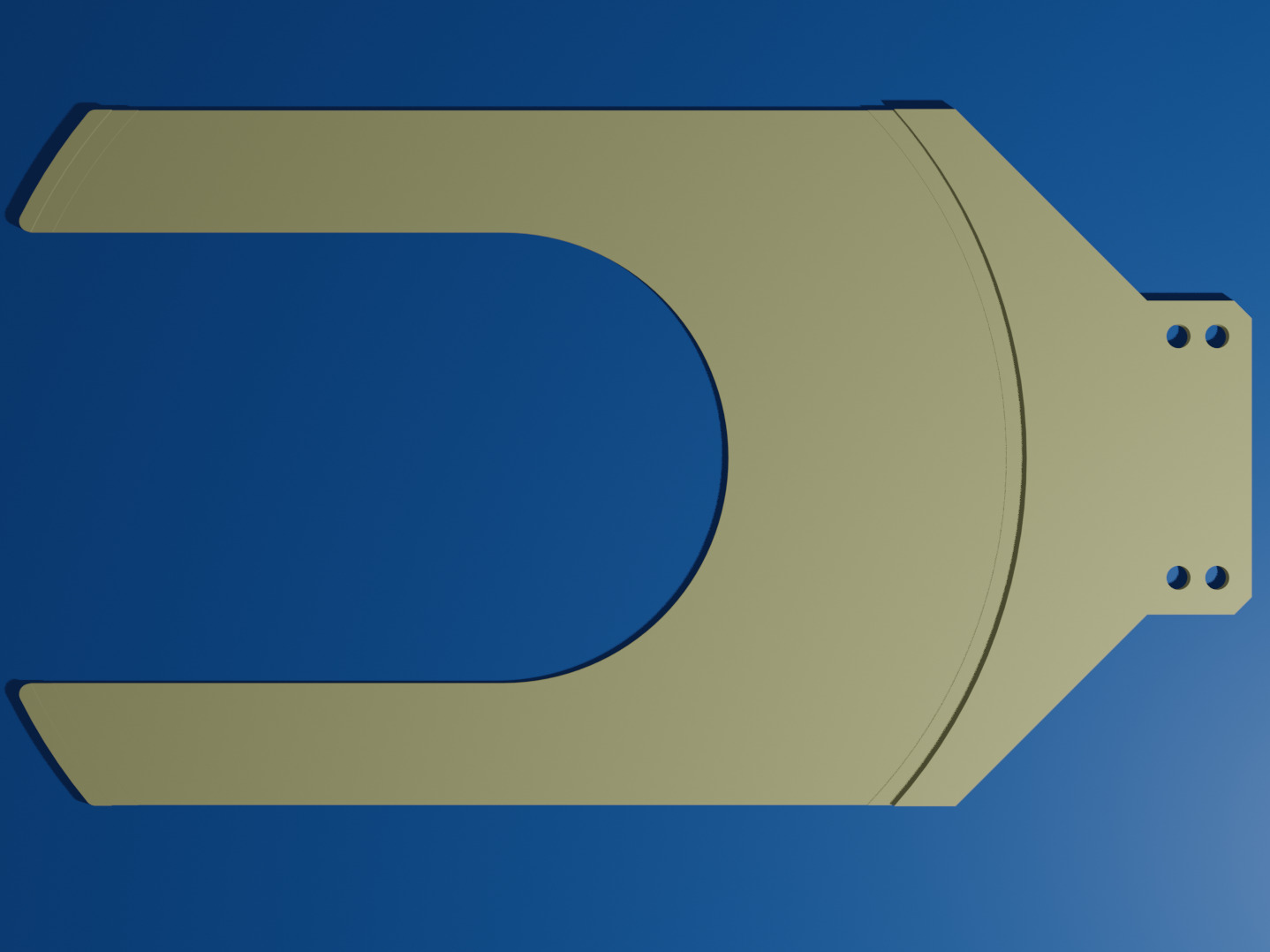

It is possible to rent our original the End Effector / Handling Arm demonstration machine. Ejectors for suction End Effector / Handling Arm are available. The equipment can be used immediately as long as compressed air is available. If you need a wrist block or other parts for installation of the device, we can make them for you. We have a lineup available for loan, so please contact us for details.

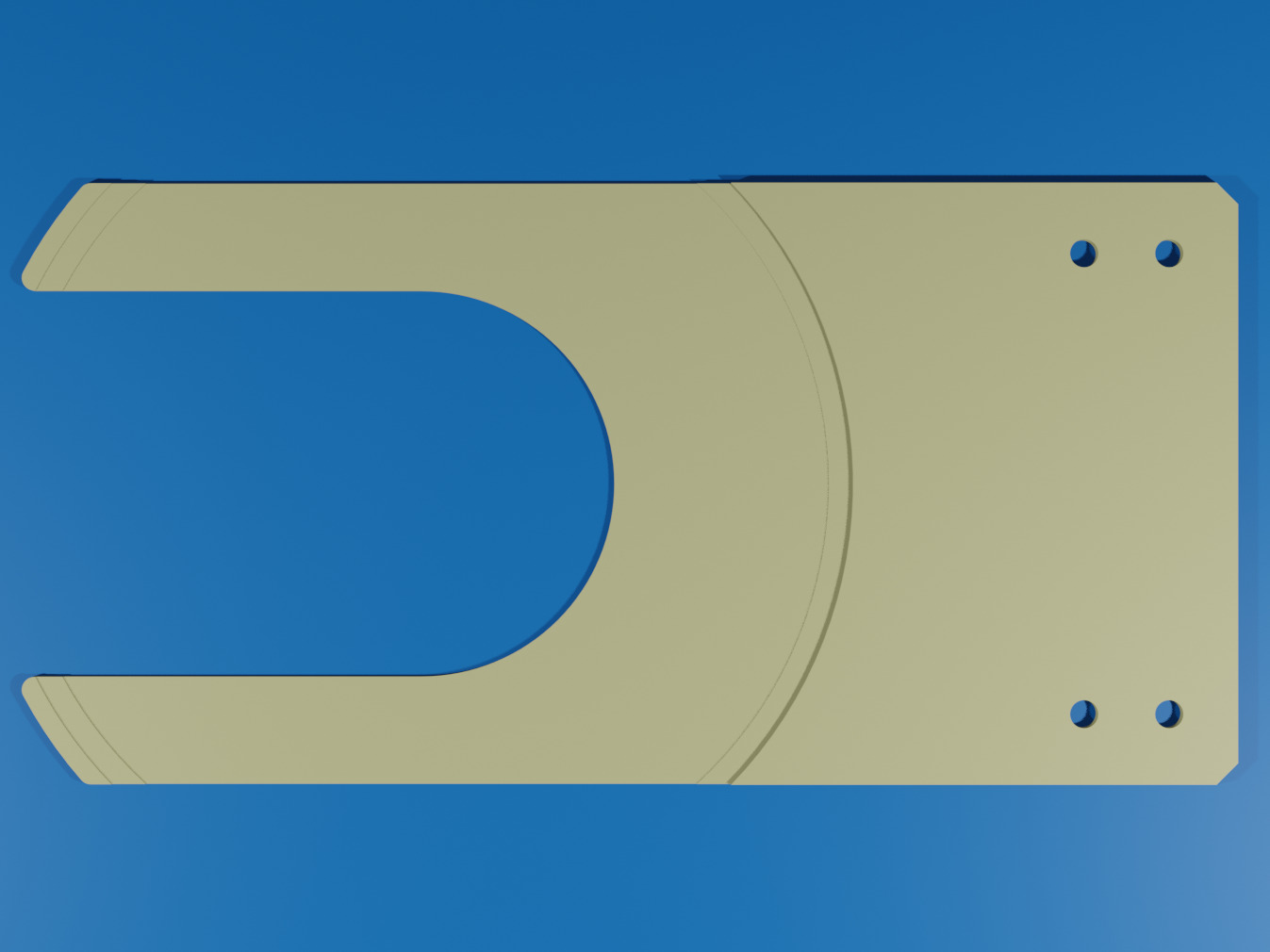

.jpg)

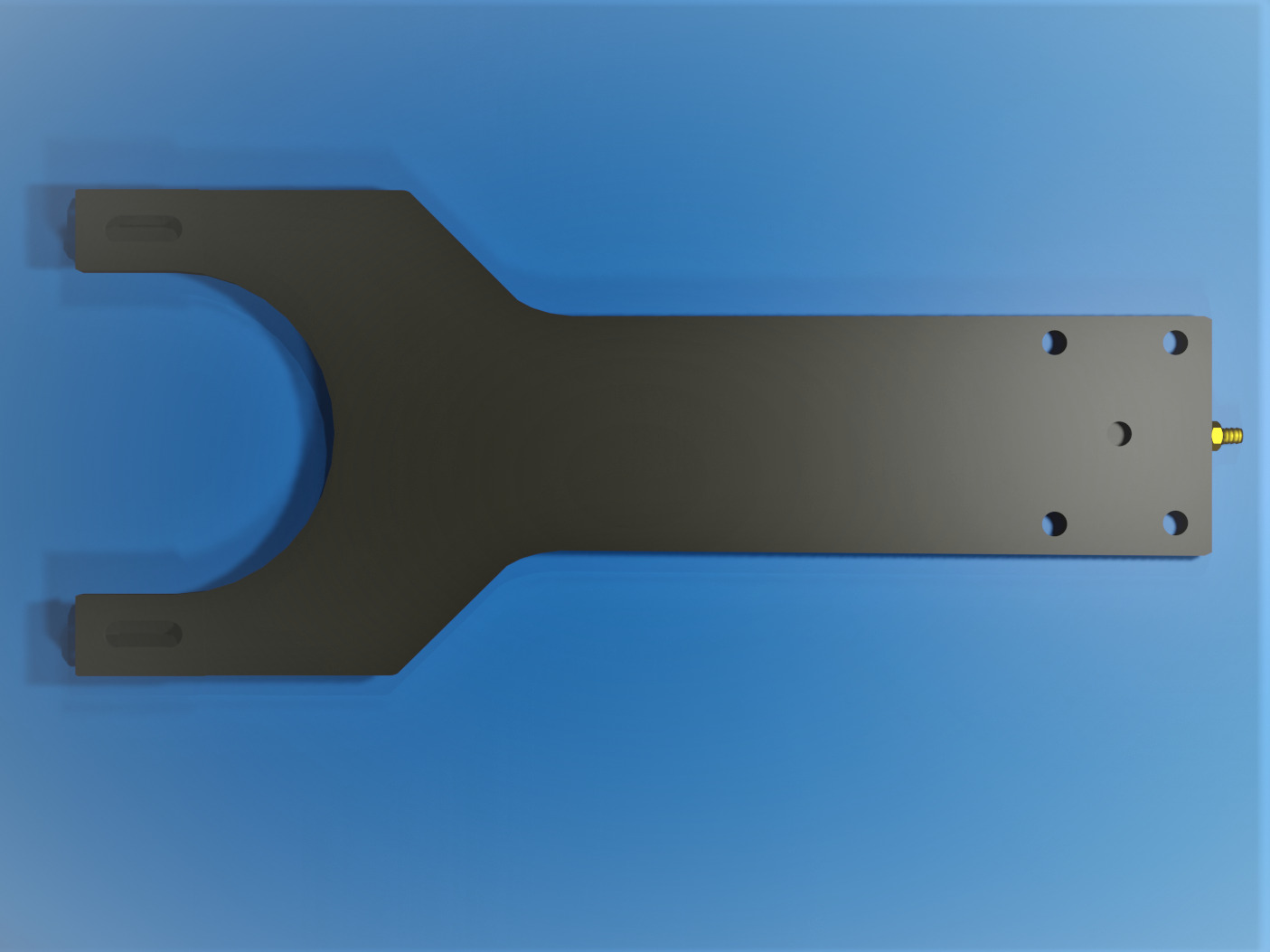

.jpg)

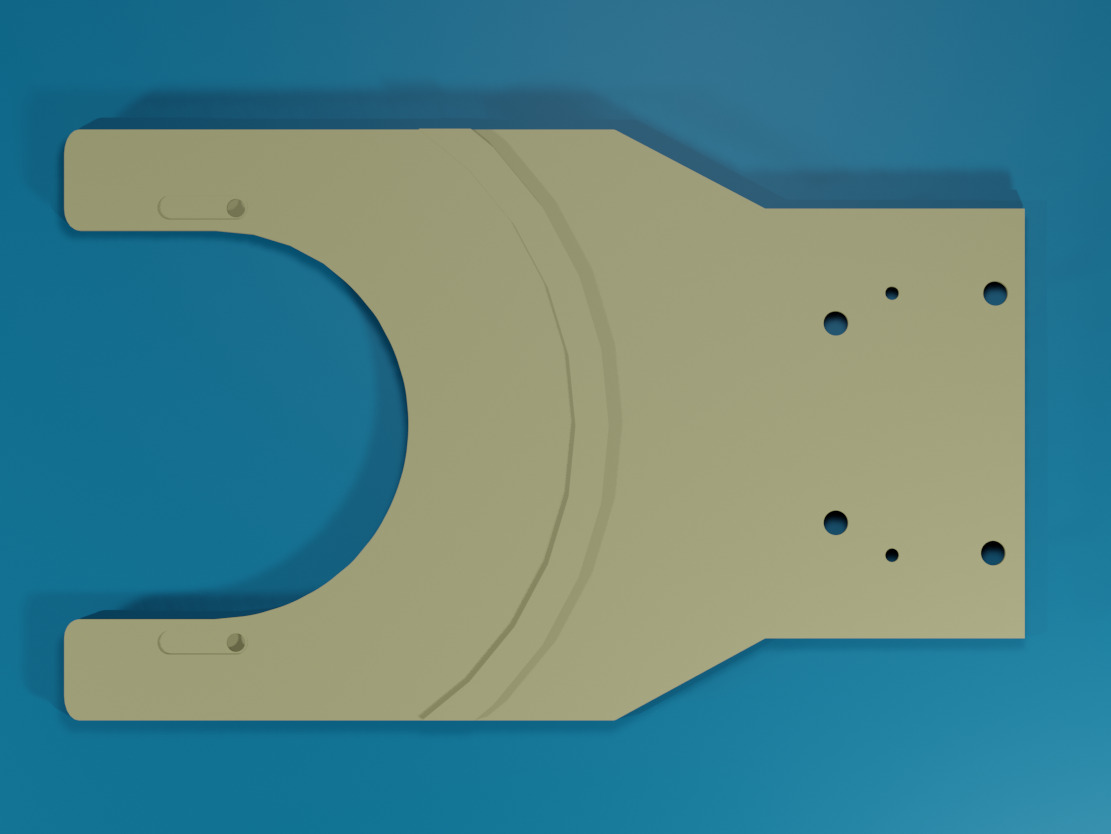

.jpg)