-

ProblemsWarped Wafer

-

Proposed EffectWarped Wafer Prevention

Improved Productivity(Improved Throughput) -

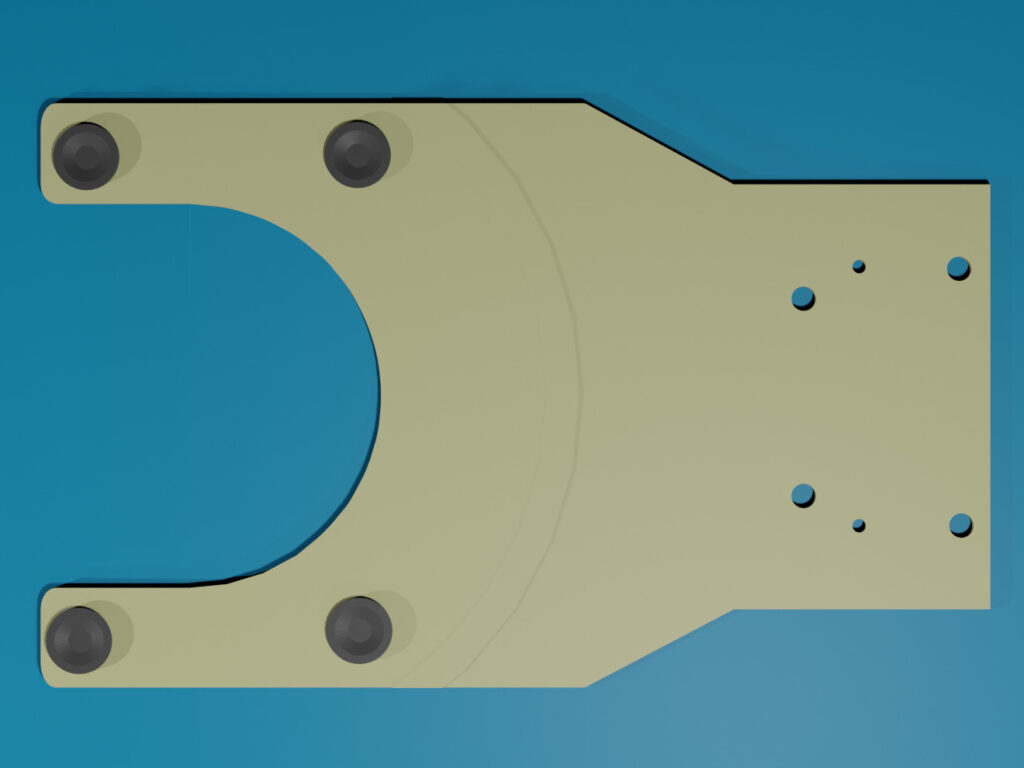

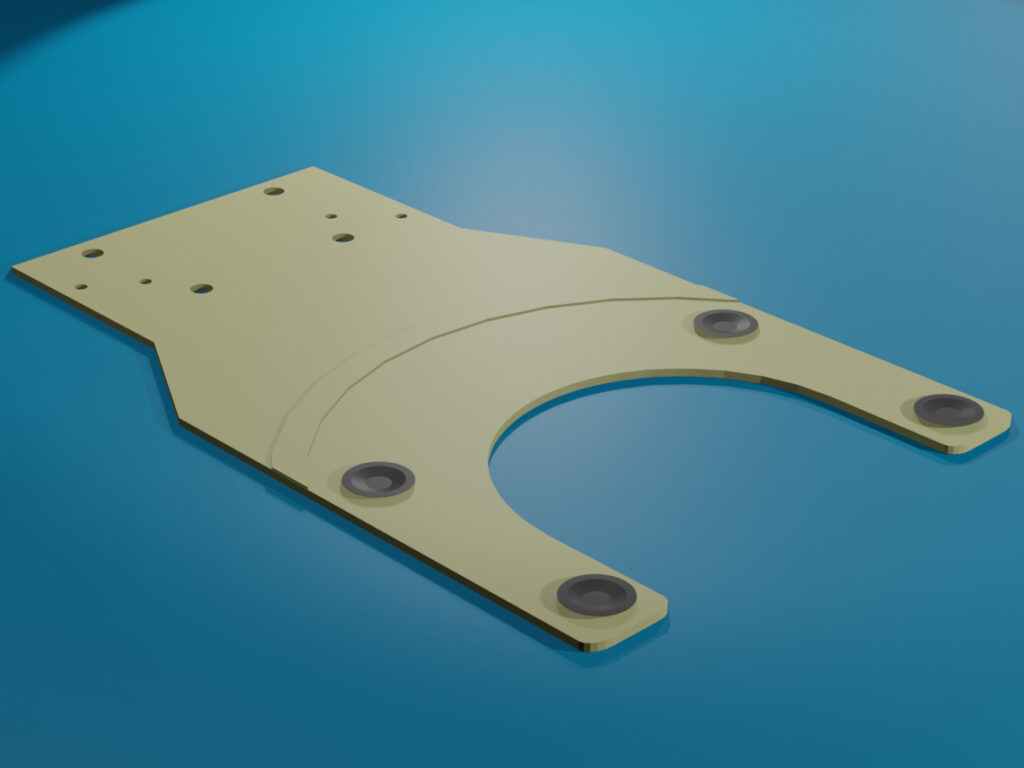

Product TypeWafer Transfer End Effector / Handling ArmPAD

Customer's concerns and problems / Before

Our proposals and improvement effects / After

We have proposed a PAD suction hand from Asuzac,and it is now possible to transfer warped wafers without any trouble.

We were able to contribute to stable facility operation without errors during transportation.

Point of the proposed example / Point

The point of this case is the minimization of the negative effect by warped wafer.

Warp wafers are generally difficult to transport, and it is necessary to stop equipment and replace End Effector / Handling Arm. However, even if the wafers warp, the use of a End Effector / Handling Arm that can transport wafers makes it possible to fundamentally prevent warp wafers.

The Fine Ceramics Division of ASUZAC Corporation, which operates the Ceramics Design Laboratory, handles everything from material development and preparation to design and manufacture, as well as surface treatment, inspection, and cleaning.

We can also offer our own coating-technology for adding functionality to ceramics materials, as well as the selection of materials such as ceramics materials with high heat resistance and conductivity, and high-purity alumina and SiC that are highly pure and prevent contamination.

If you have any questions about warped wafers, please feel free to contact us.

Integrated response from processing to development of ceramic materials !

Please feel free to contact us !

Business hours: 9:00-17:00 (closed on Saturdays, Sundays and Holidays)

.jpg)

.jpg)

When transferring warped wafers, we consulted with us that the normal suction End Effector / Handling Arm has not been able to transfer them.

Since errors occur frequently during the transfer of warped wafers, they said that this has led to a decrease in productivity.