-

ProblemsPlasma Resistance

Heat Resistance

Reflectance -

Proposed EffectWear Resistance Improvement

Improved Heat Resistance

Improved Plasma Resistance -

Product TypeOther

Customer's concerns and problems / Before

Our proposals and improvement effects / After

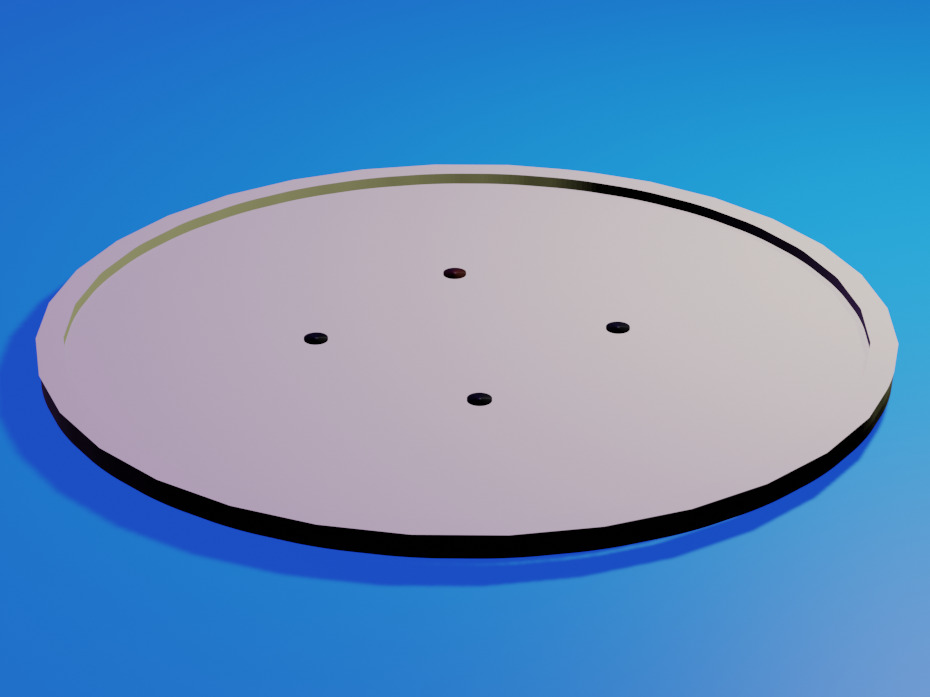

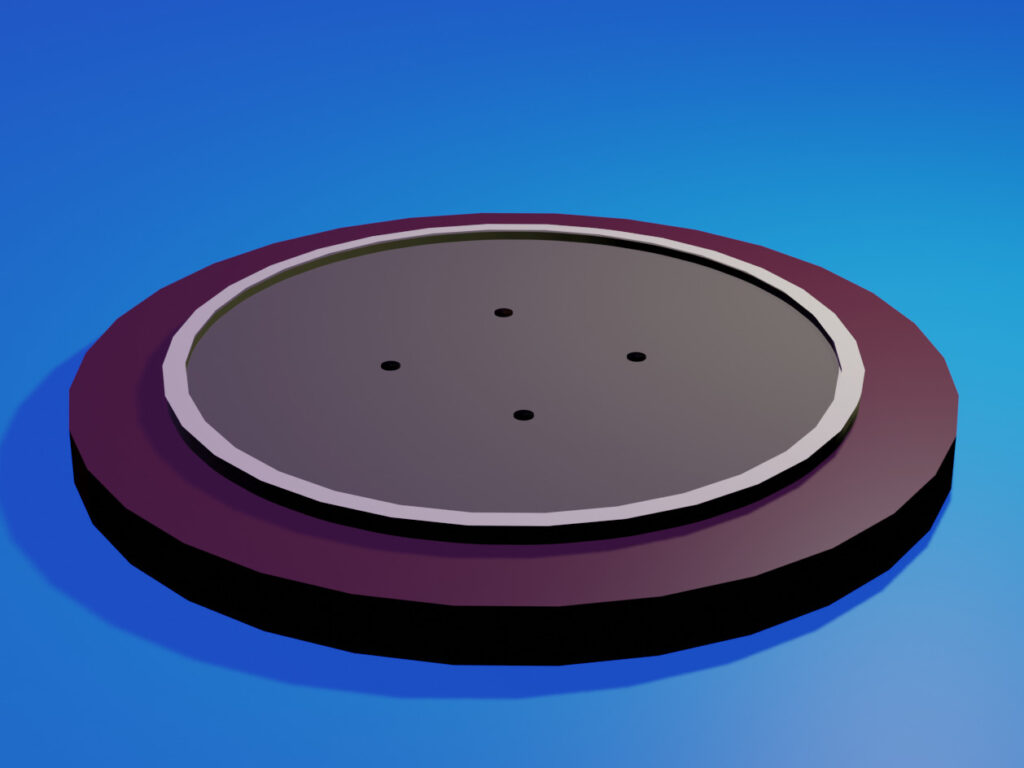

We proposed the manufacture of parts using Black Alumina, which has high heat resistance.

Black Alumina is a material used when low reflectance is required in parts for light sources, microscopes, and inspection equipment.

It has a longer life (higher plasma resistance) and better color retention than quartz.

It was manufactured as a ceramics part that does not color and wear even in high-temperature environments, resulting in a cost reduction.

Point of the proposed example / Point

The point of this case is the selection of the most suitable material for the usage environment.

Unlike metal materials, which are widely known for specifications and characteristics, ceramics materials have different characteristics for each manufacturer.

In extreme terms, it is also possible for users to mix materials on a part-by-part basis, so improvements can be made from materials according to the required performance.

The Fine Ceramics Division of ASUZAC Corporation, which operates the Ceramics Design Laboratory, handles everything from material development and preparation to design and manufacture, as well as surface treatment, inspection, and cleaning.

We can also offer our own coating-technology for adding functionality to ceramics materials, as well as the selection of materials such as ceramics materials with high heat resistance and conductivity, and high-purity alumina and SiC that are highly pure and prevent contamination.

If you have any questions about ceramic components, please feel free to contact us.

Integrated response from processing to development of ceramic materials !

Please feel free to contact us !

Business hours: 9:00-17:00 (closed on Saturdays, Sundays and Holidays)

.jpg)

.jpg)

Consult with us about the black pin parts used to align the wafer when it is placed on the quartz plate.

In a high-temperature environment and at 750 ℃, the current parts are consuming a lot of time, so we looked for highly durable ceramic parts.