-

ProblemsAbrasion

Static Electricity

Part Replacement Time

Cost -

Proposed EffectMan-Hour Reduction

Cost Reduction

Improved Functionality

Improved Productivity

Wear Resistance -

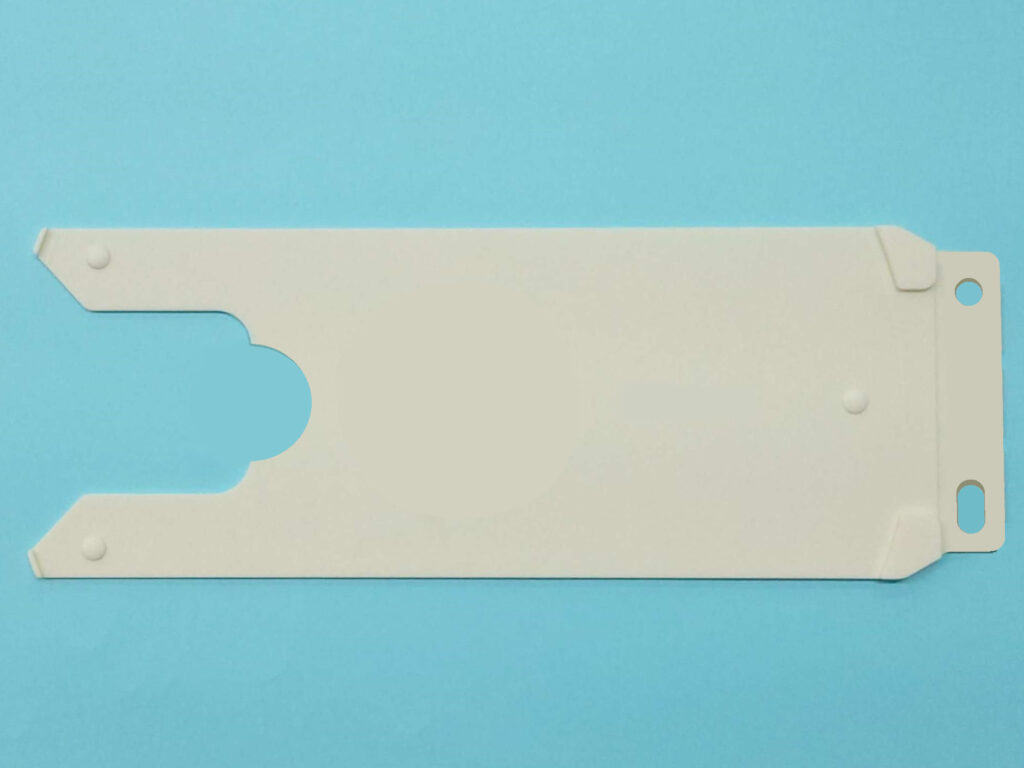

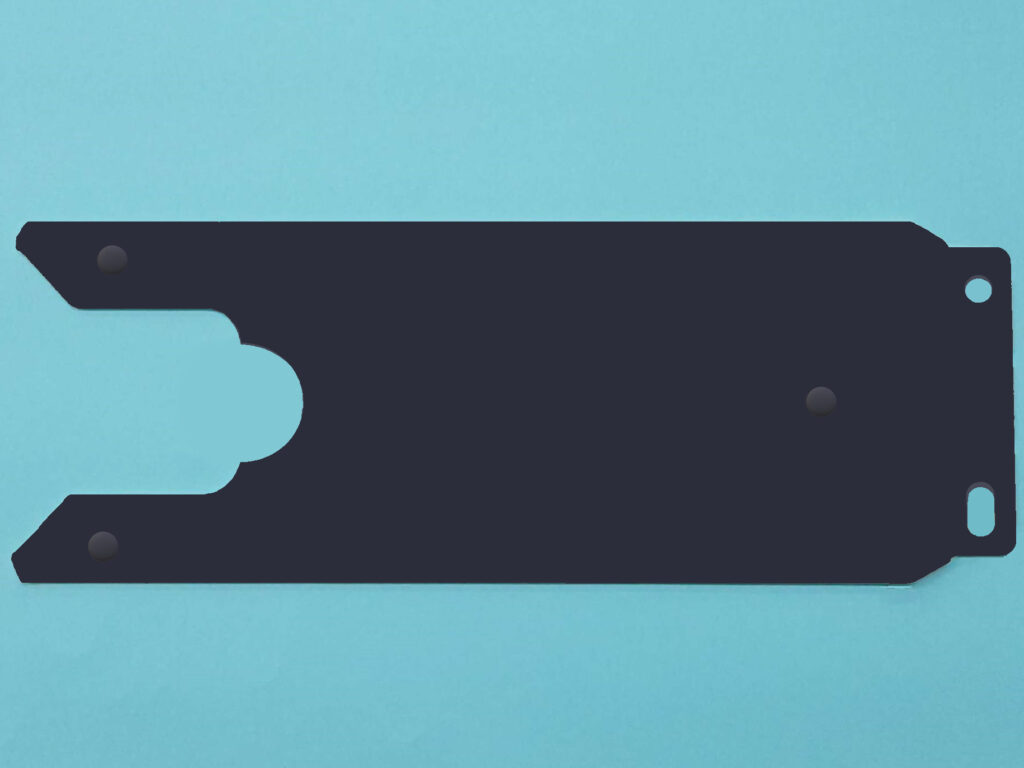

Product TypeWafer Transfer End Effector / Handling ArmPAD

Customer's concerns and problems / Before

Our proposals and improvement effects / After

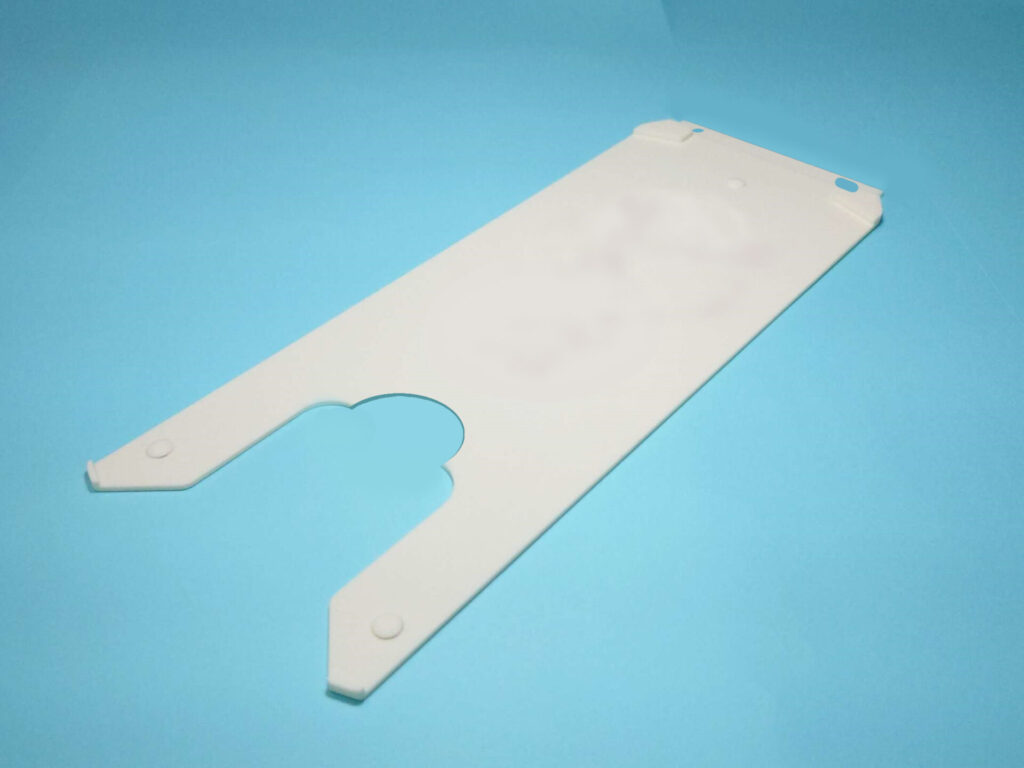

In response, the Ceramics Design Laboratory proposed changing the specifications of the three-point wafer holding section (convex) from a one-piece processing to a removable PAD.

As a consequence, there is no need to replace the transfer hands themselves, and only the worn PAD needs to be replaced, resulting in a significant cost reduction.

At the same time, we proposed a Black Alumina-coated transport End Effector / Handling Arm with high wear resistance and high static electricity diffusion properties, which also contributed to extending the life of our products.

Point of the proposed example / Point

The point of this case is that the replacement cost is drastically reduced by replacing the holding part with a removable PAD even if the Transfer End Effector / Handling Arm themselves do not need to be replaced.

Though the initial cost is a little higher than the integrated machining, the cost is lower when the running cost is considered by PAD.

The Fine Ceramics Division of ASUZAC Corporation, which operates the Ceramics Design Laboratory, handles everything from material development and preparation to design and manufacture, as well as surface treatment, inspection, and cleaning.

We can also offer our own coating-technology for adding functionality to ceramics materials, as well as the selection of materials such as ceramics materials with high heat resistance and conductivity, and high-purity alumina and SiC that are highly pure and prevent contamination.

If you are not sure of the shape design and cost reduction of the wafer Transfer End Effector / Handling Arm, please feel free to contact us.

Integrated response from processing to development of ceramic materials !

Please feel free to contact us !

Business hours: 9:00-17:00 (closed on Saturdays, Sundays and Holidays)

.jpg)

.jpg)

A customer of a semiconductor device manufacturer asked, “When the wafer holding part of a robot End Effector / Handling Arm for etching equipment deteriorates and wears out, the entire End Effector / Handling Arm has to be replaced, which is very expensive.” The customer asked us, “Can you do something about it?”