-

ProblemsPart Replacement Time

Functionality -

Proposed EffectMan-Hour Reduction

Cost Reduction

Improved Functionality

Improved Productivity -

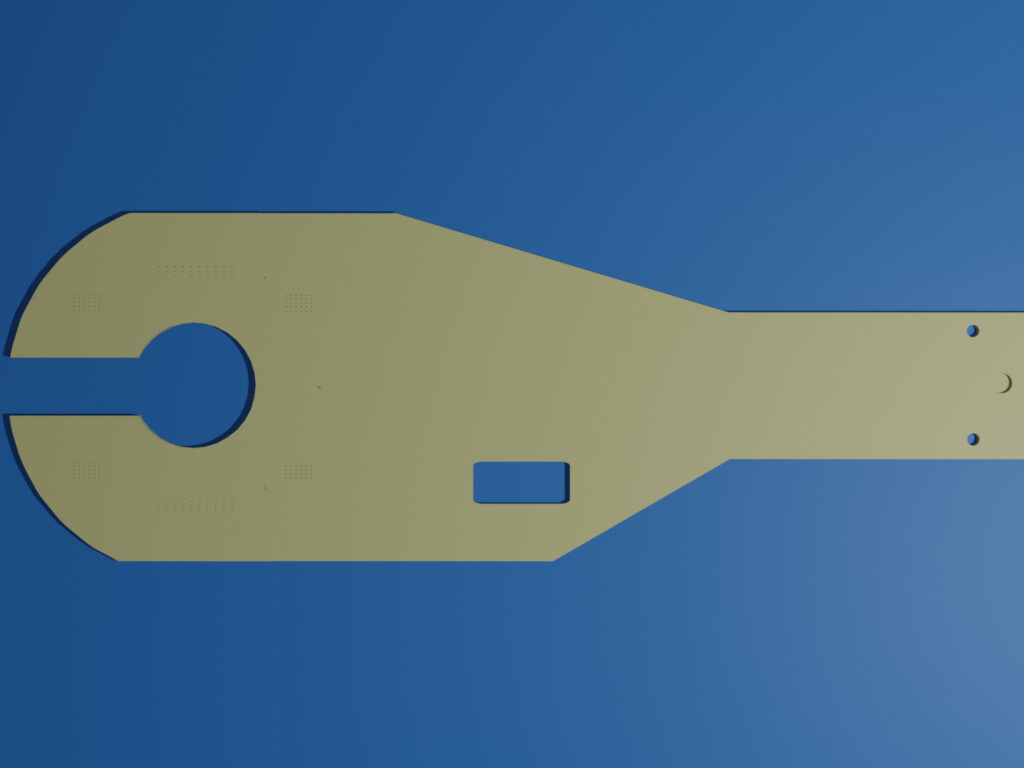

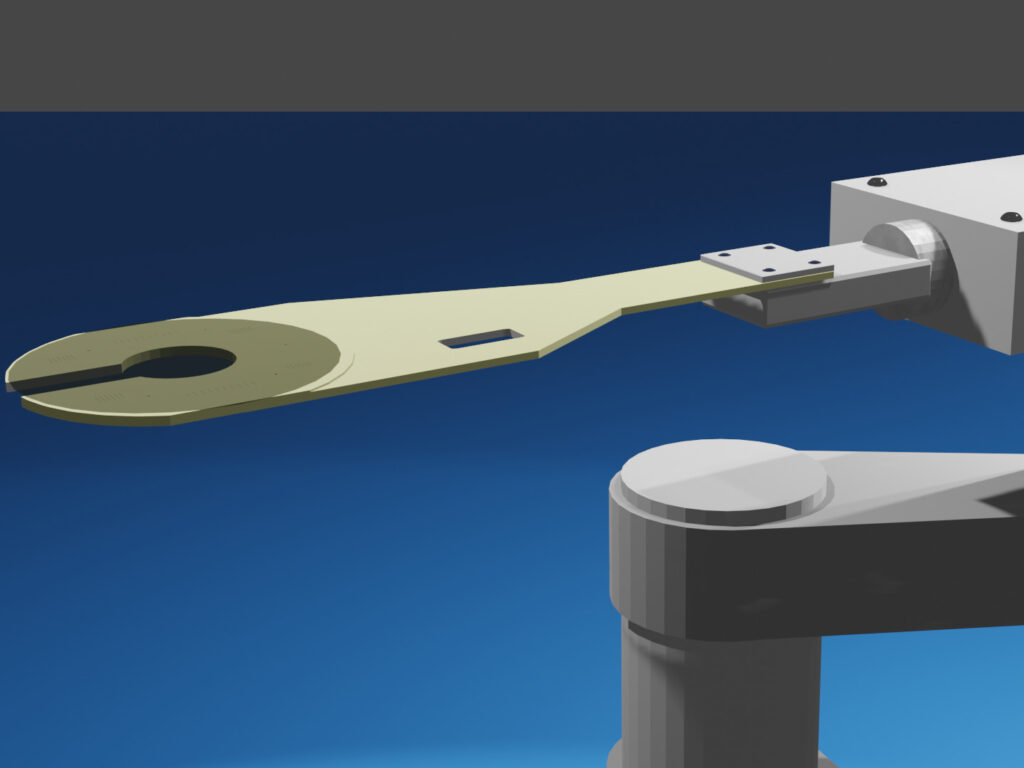

Product TypeWafer Transfer End Effector / Handling Arm

Customer's concerns and problems / Before

Our proposals and improvement effects / After

In response, the Ceramics Design Laboratory proposed a multi-functional hand with an integrated cavity that allows the wafer to be suctioned and floated with a single Transfer End Effector / Handling Arm.

We designed the Bernoulli method for ascent.

Since one Transfer End Effector / Handling Arm can be used to absorb and float wafers, the number of man-hours required to replace the Transfer End Effector / Handling Arm can be reduced, which also leads to cost reductions.

Point of the proposed example / Point

The point of this case is that the multiple wafer Transfer End Effector / Handling Arm with different transfer systems were used, which resulted in a reduction in man-hours and cost by replacing the wafers with a multi-function End Effector / Handling Arm with both suction and floating functions.

Depending on the transported object (wafer, film, etc.), there are cases where the suction method is suitable and cases where the non-contact holding is suitable by levitation, so it is necessary to select an appropriate transportation method.

The Fine Ceramics Division of ASUZAC Corporation, which operates the Ceramics Design Laboratory, handles everything from material development and preparation to design and manufacture, as well as surface treatment, inspection, and cleaning.

We can also offer our own coating-technology for adding functionality to ceramics materials, as well as the selection of materials such as ceramics materials with high heat resistance and conductivity, and high-purity alumina and SiC that are highly pure and prevent contamination.

Please feel free to contact us if you have any problems with the cost of the Transfer End Effector / Handling Arm or the number of replacement steps.

Integrated response from processing to development of ceramic materials !

Please feel free to contact us !

Business hours: 9:00-17:00 (closed on Saturdays, Sundays and Holidays)

.jpg)

.jpg)

We received a consultation from a semiconductor manufacturing equipment manufacturer that, “We use several kinds of wafer Transfer End Effector / Handling Arm in the post-process, inspection, and cleaning processes, but they are troublesome because of the trouble of replacing them. Isn’t there any good proposal?”