|

Product Name

|

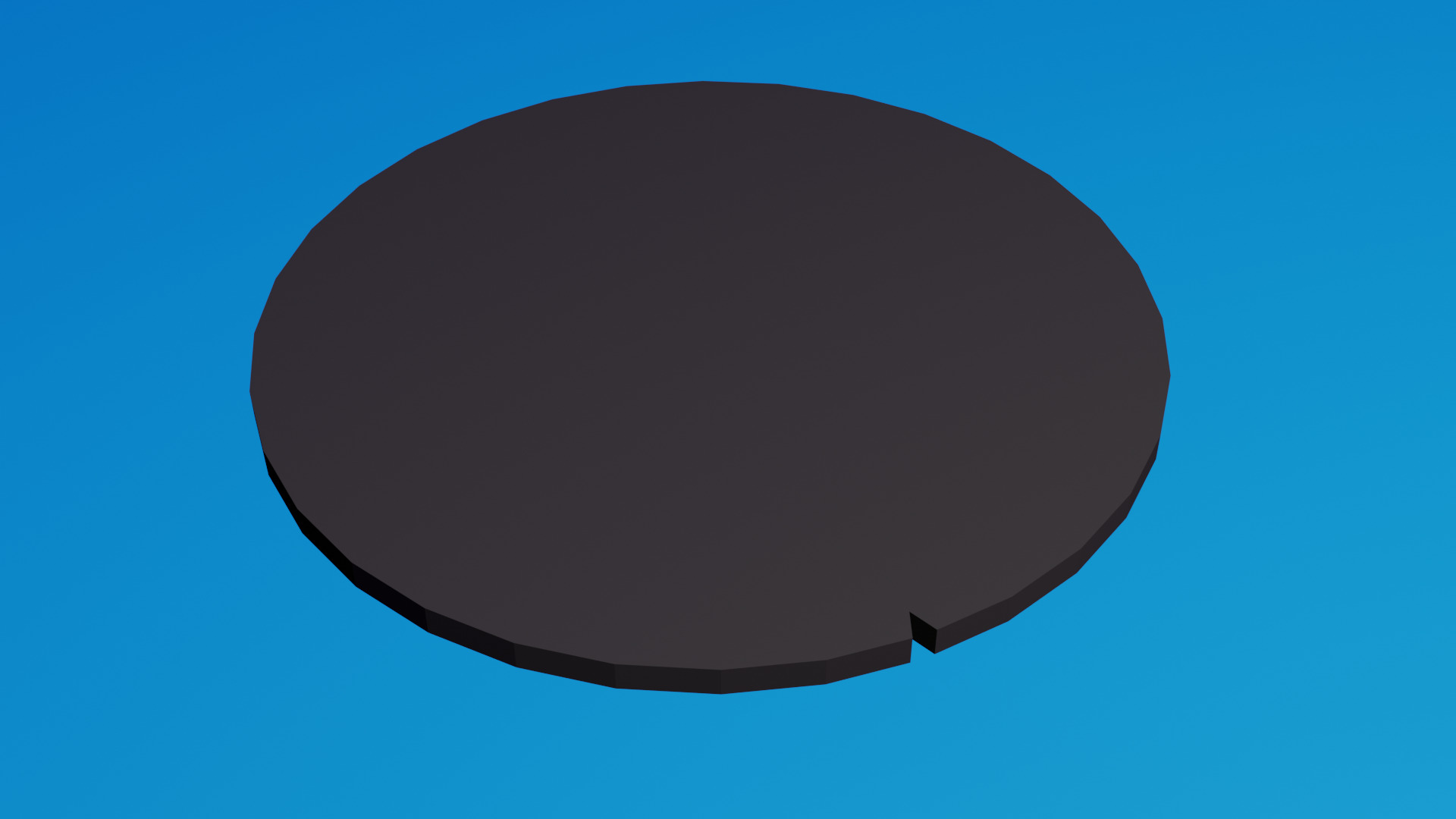

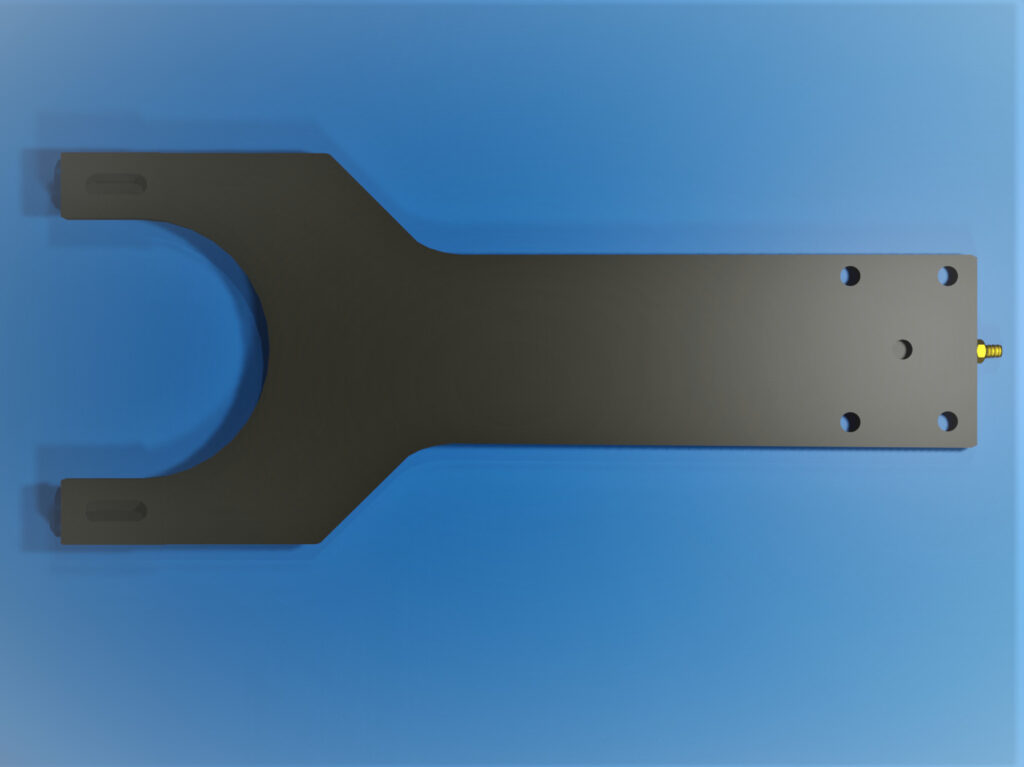

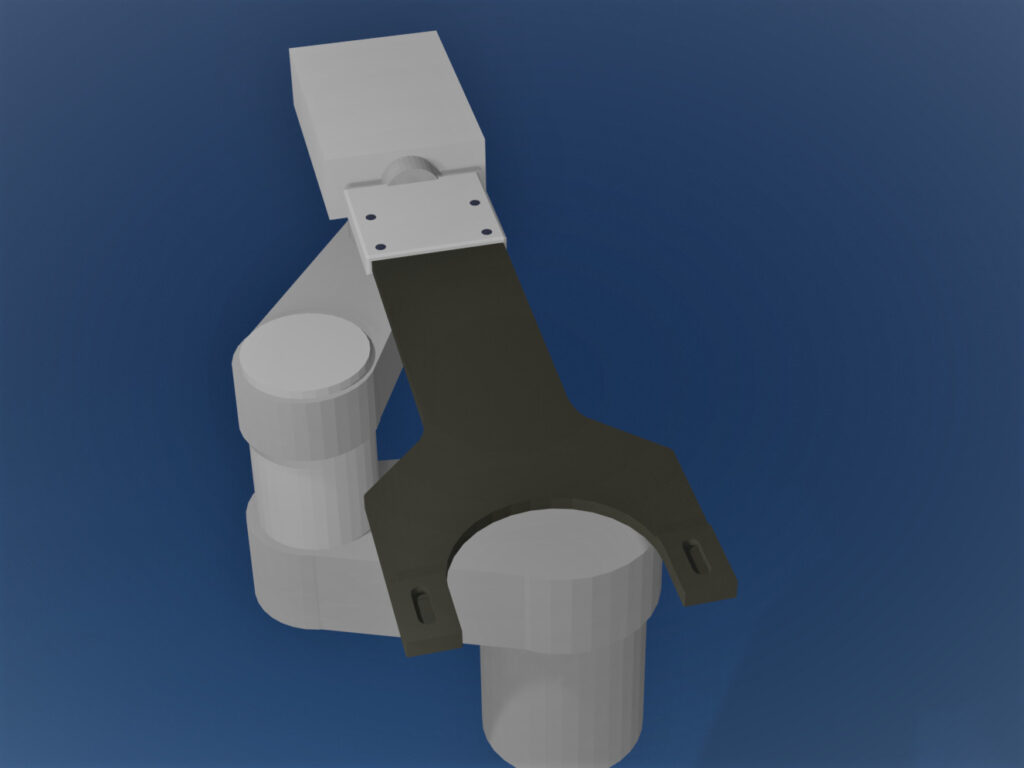

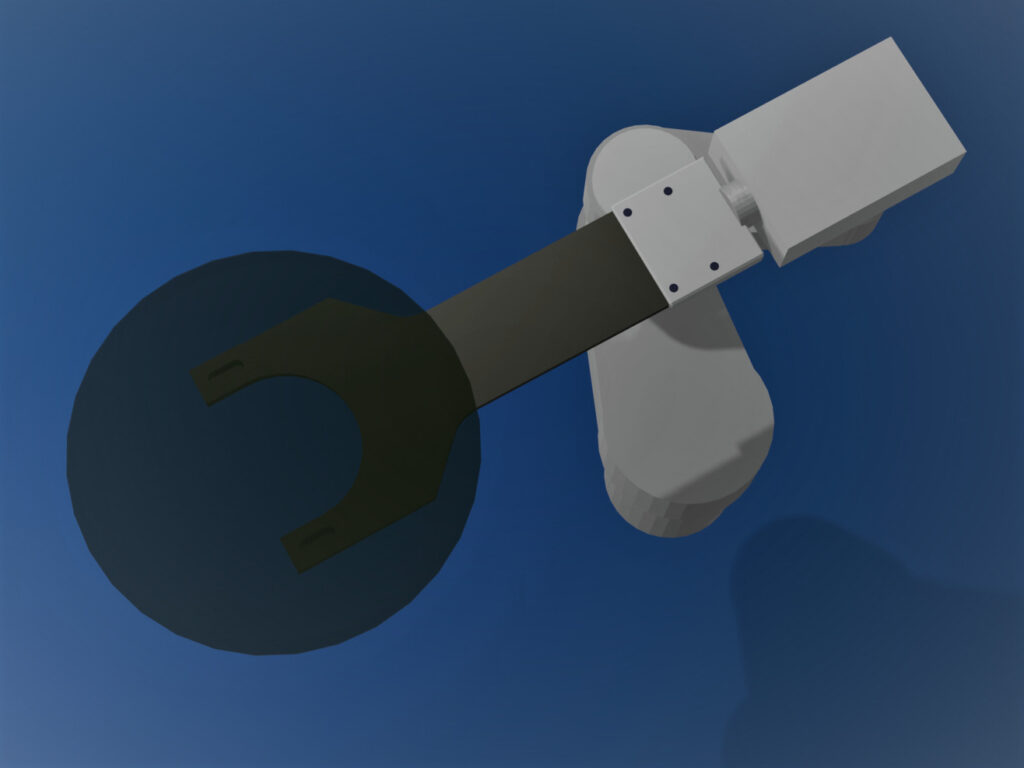

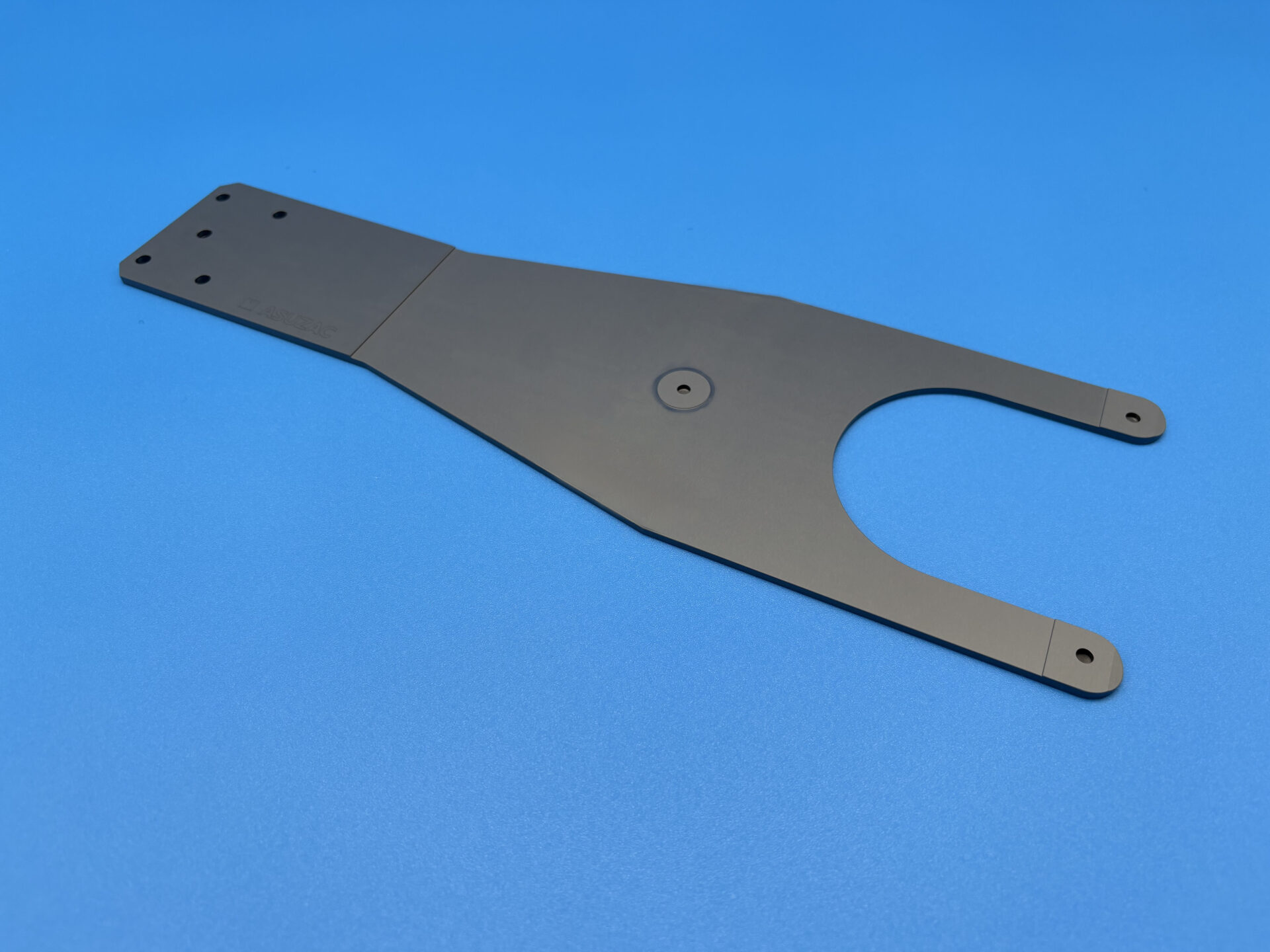

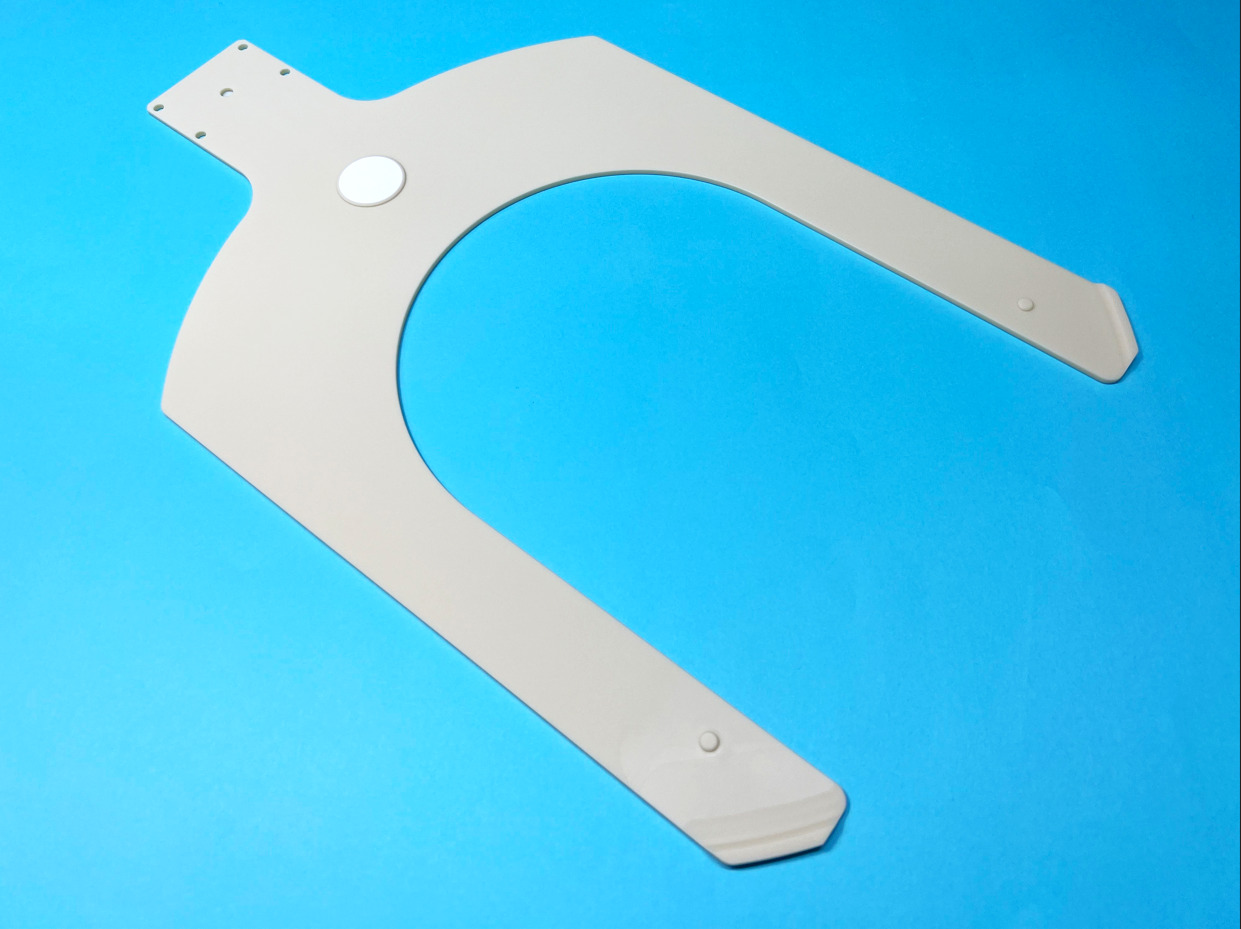

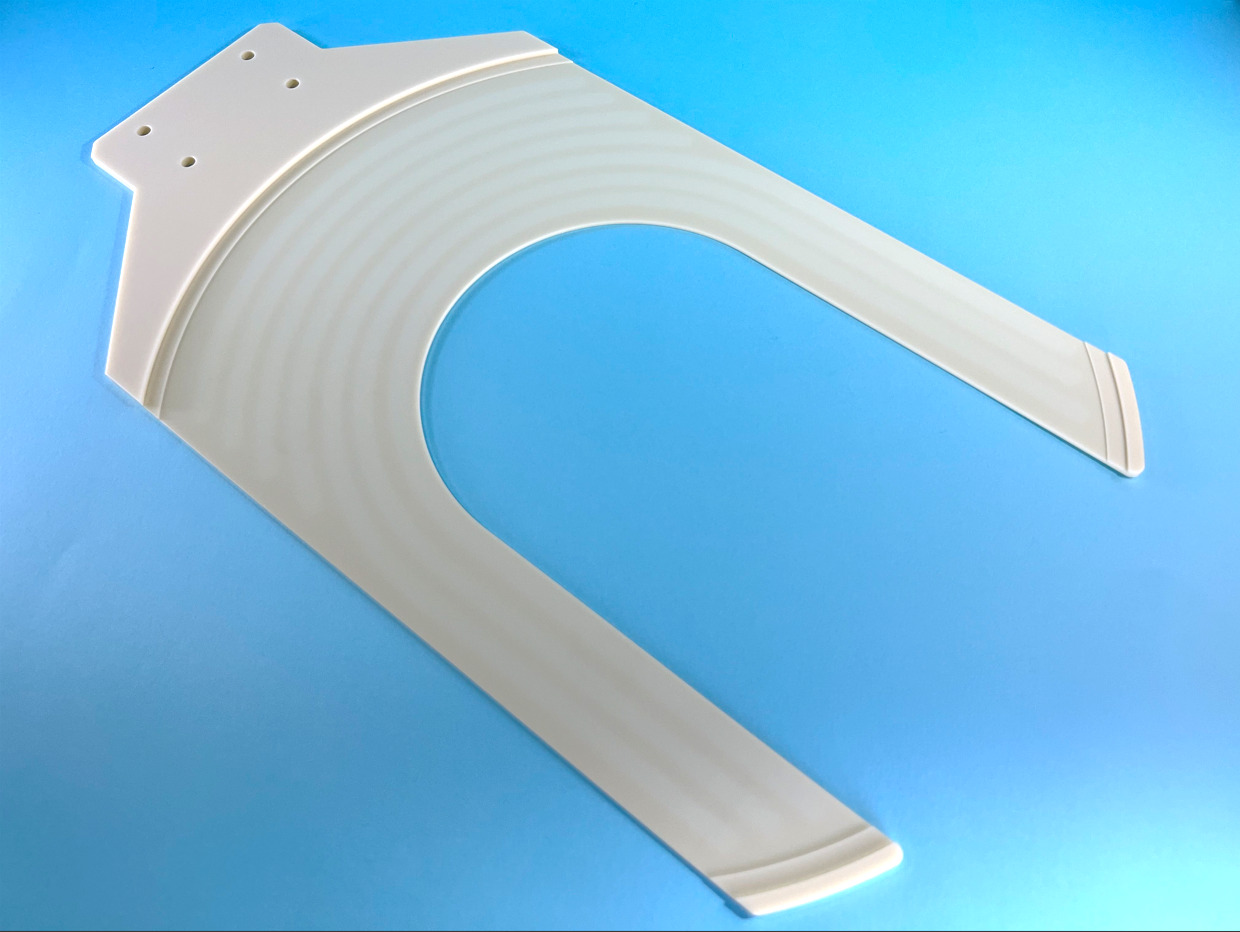

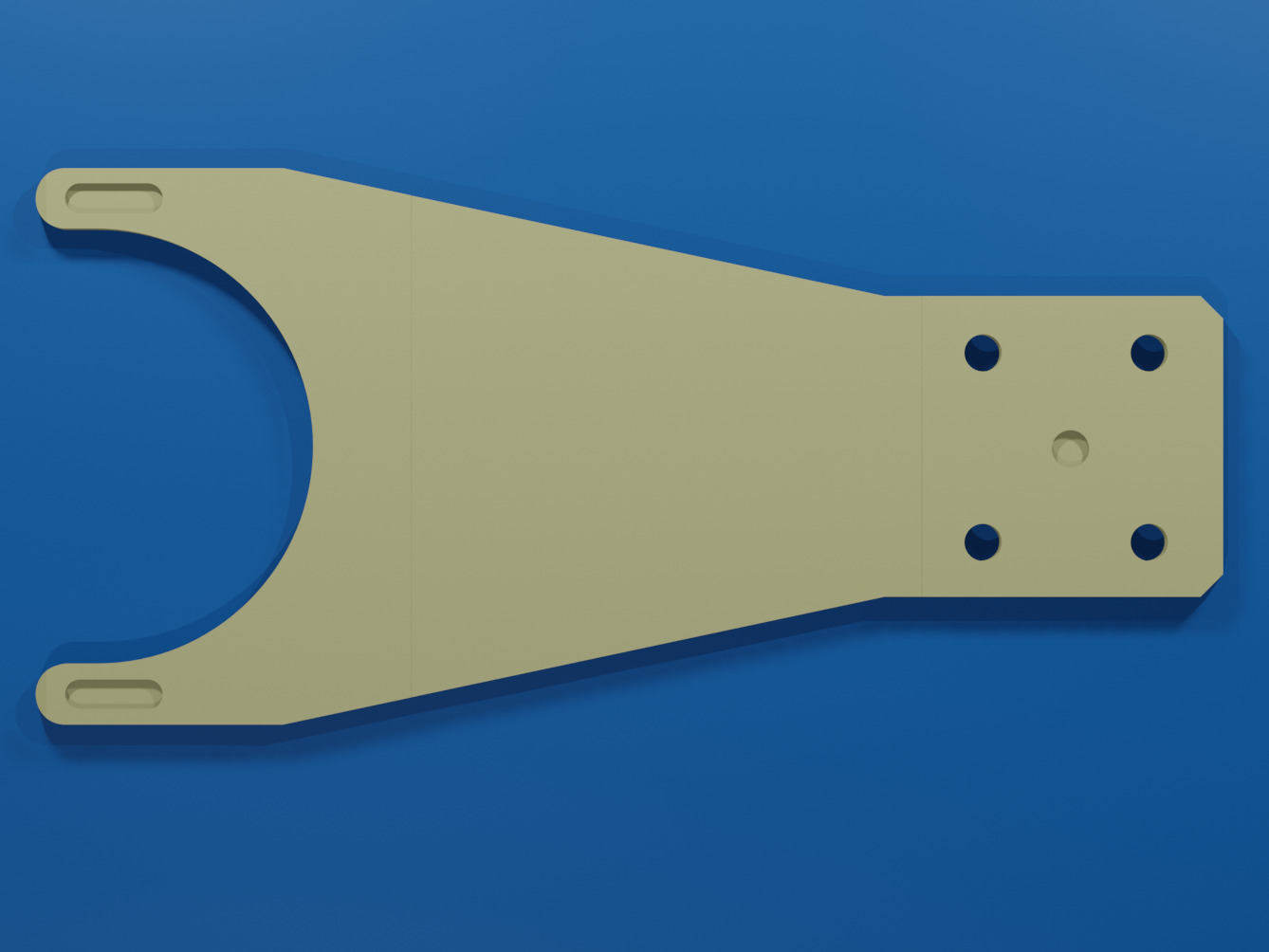

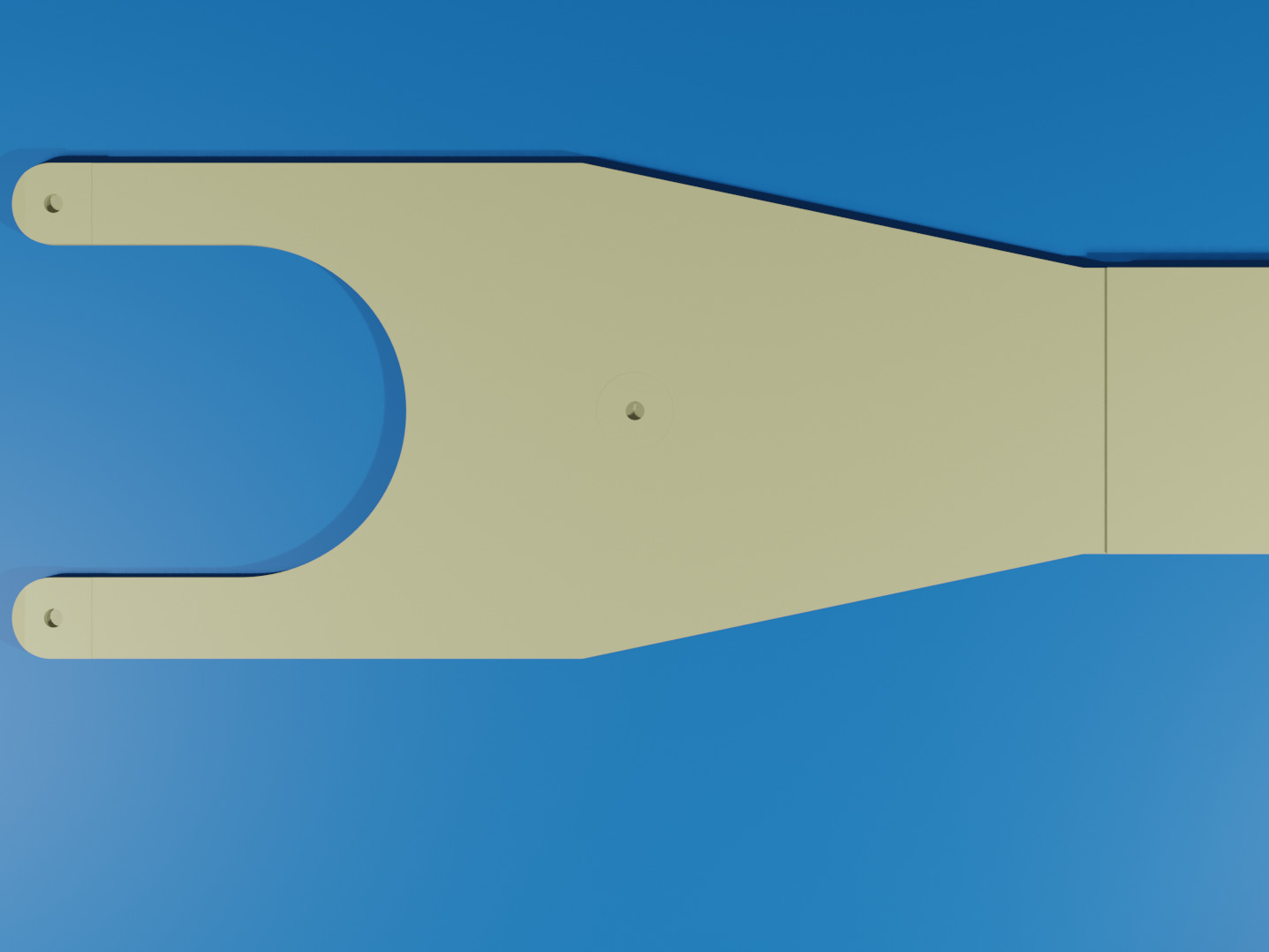

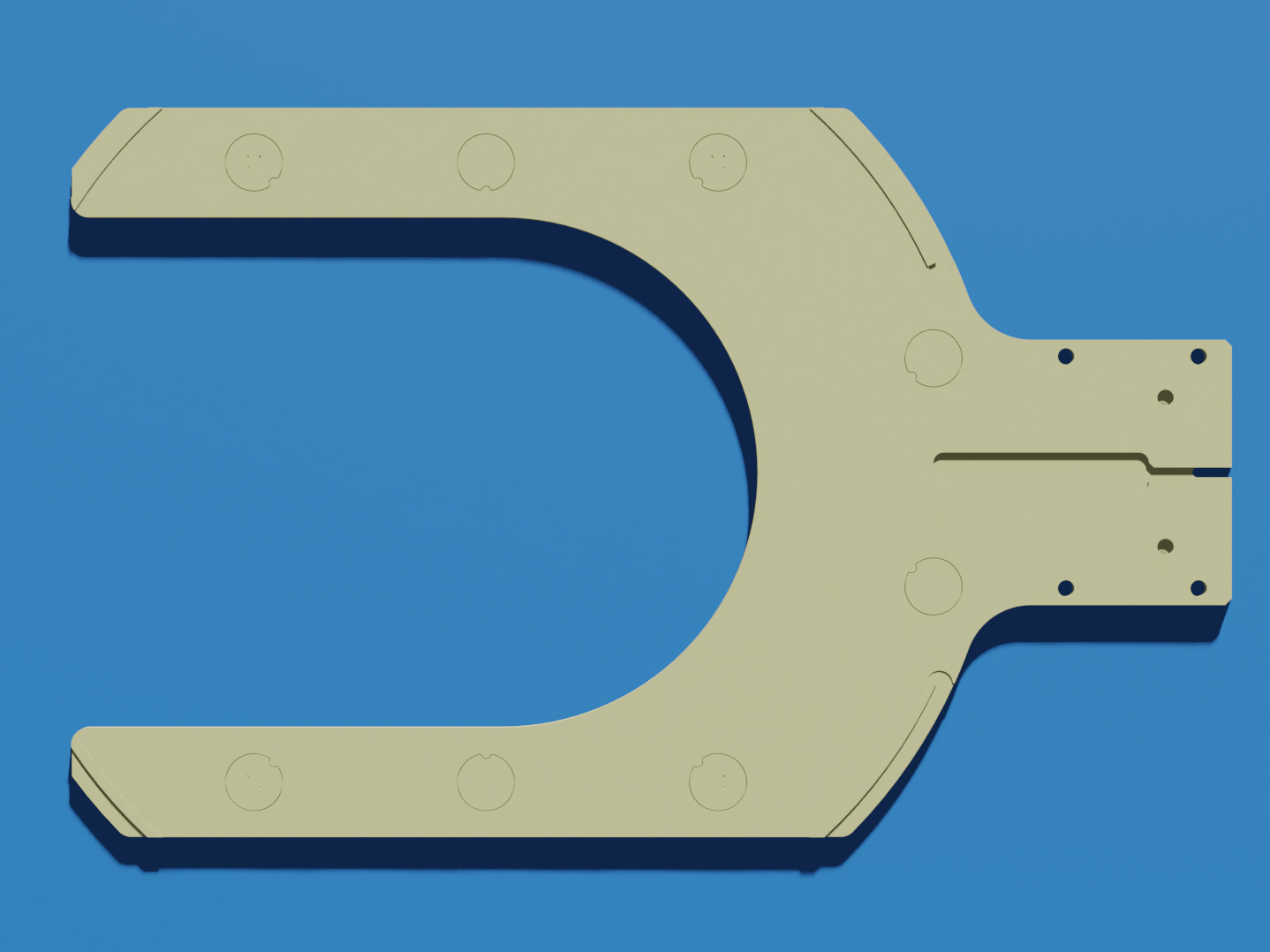

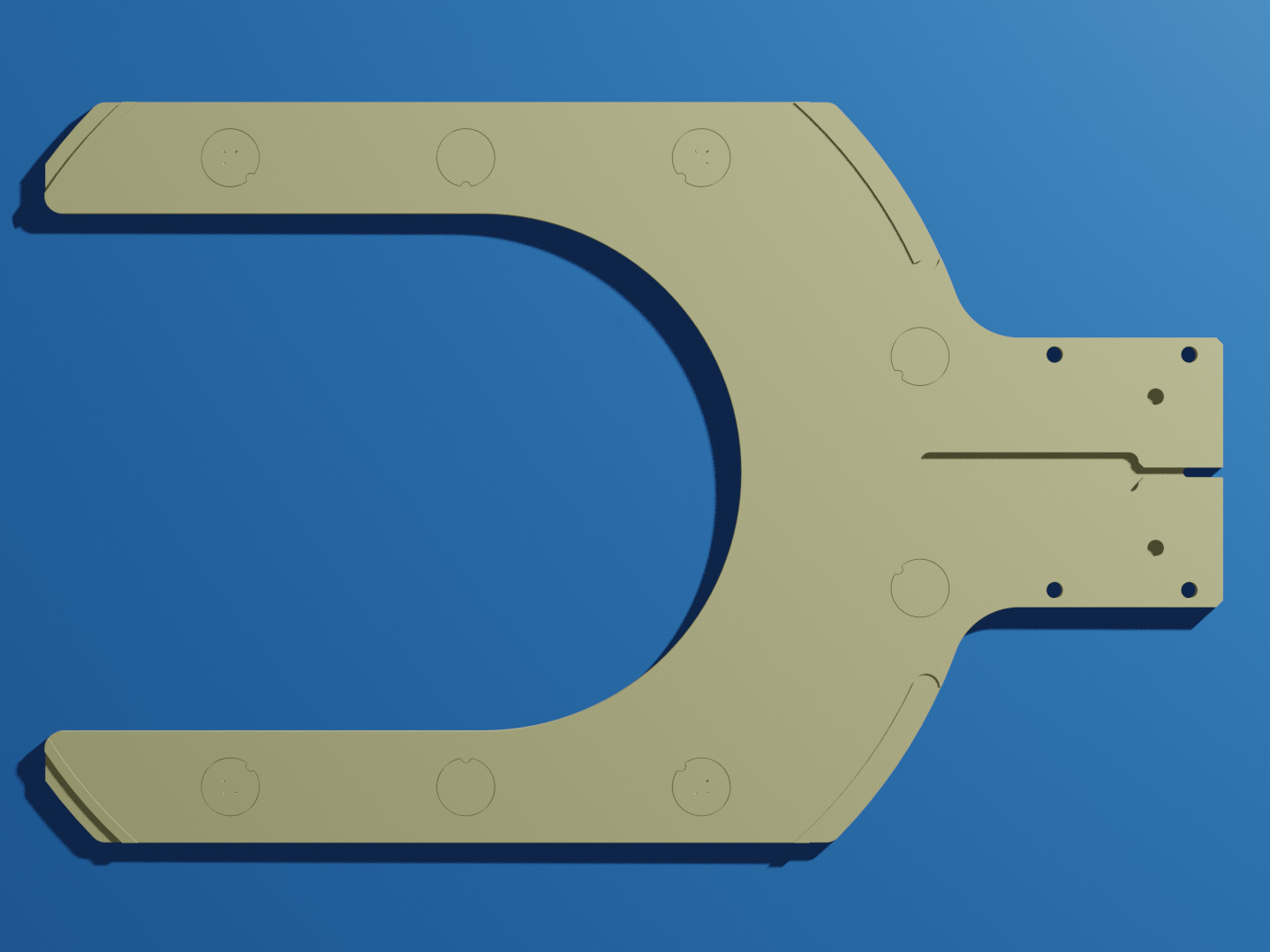

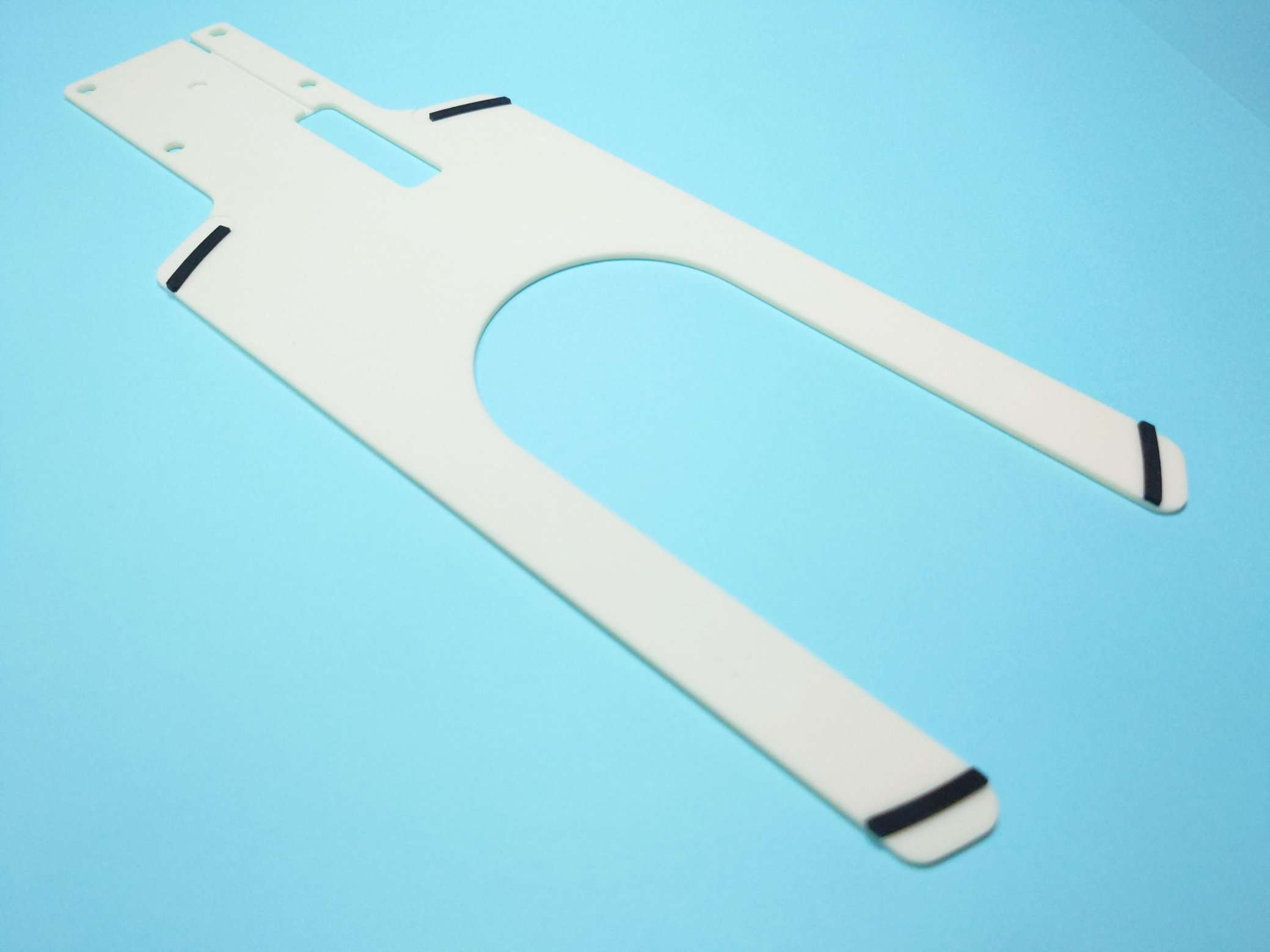

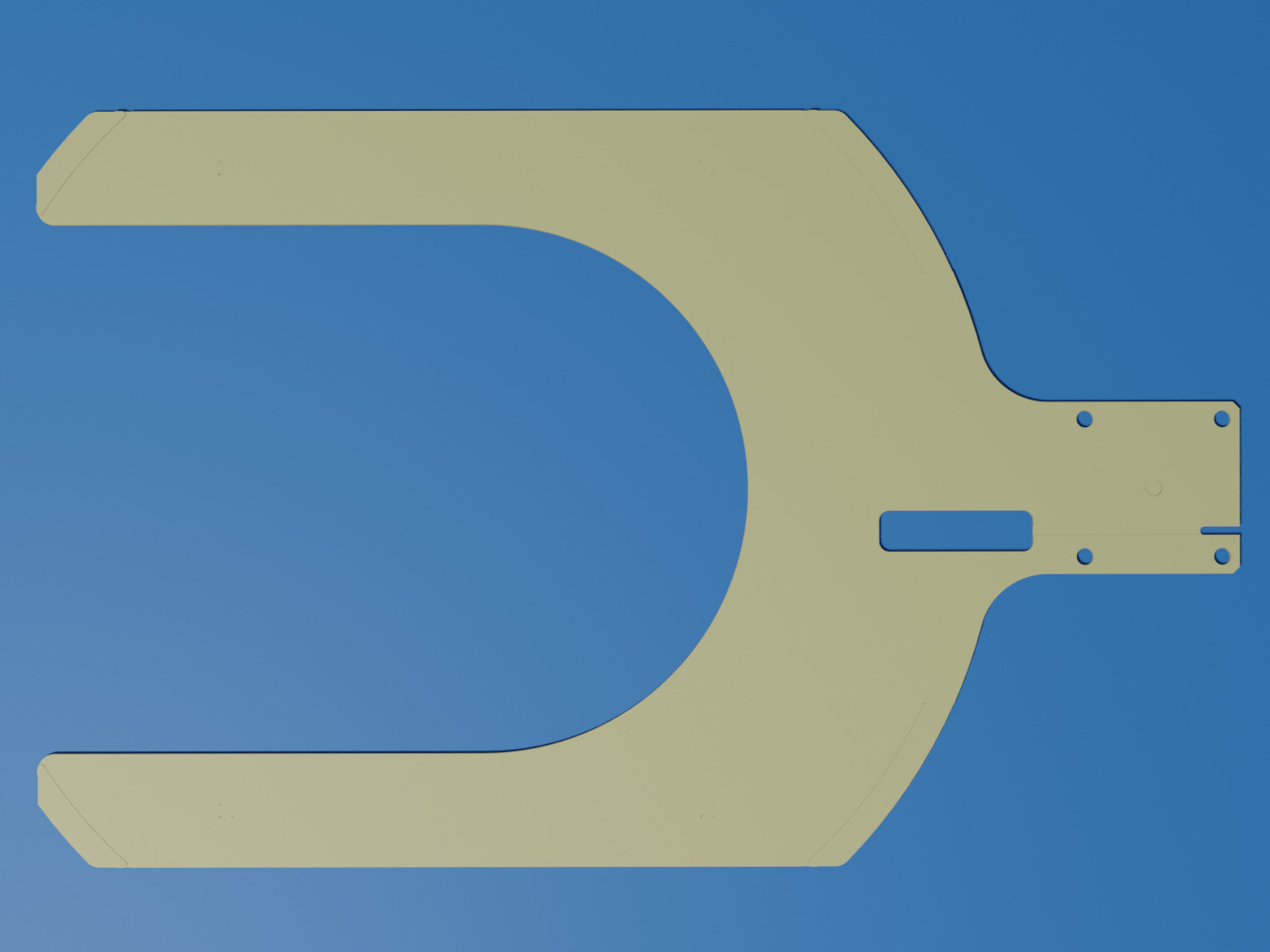

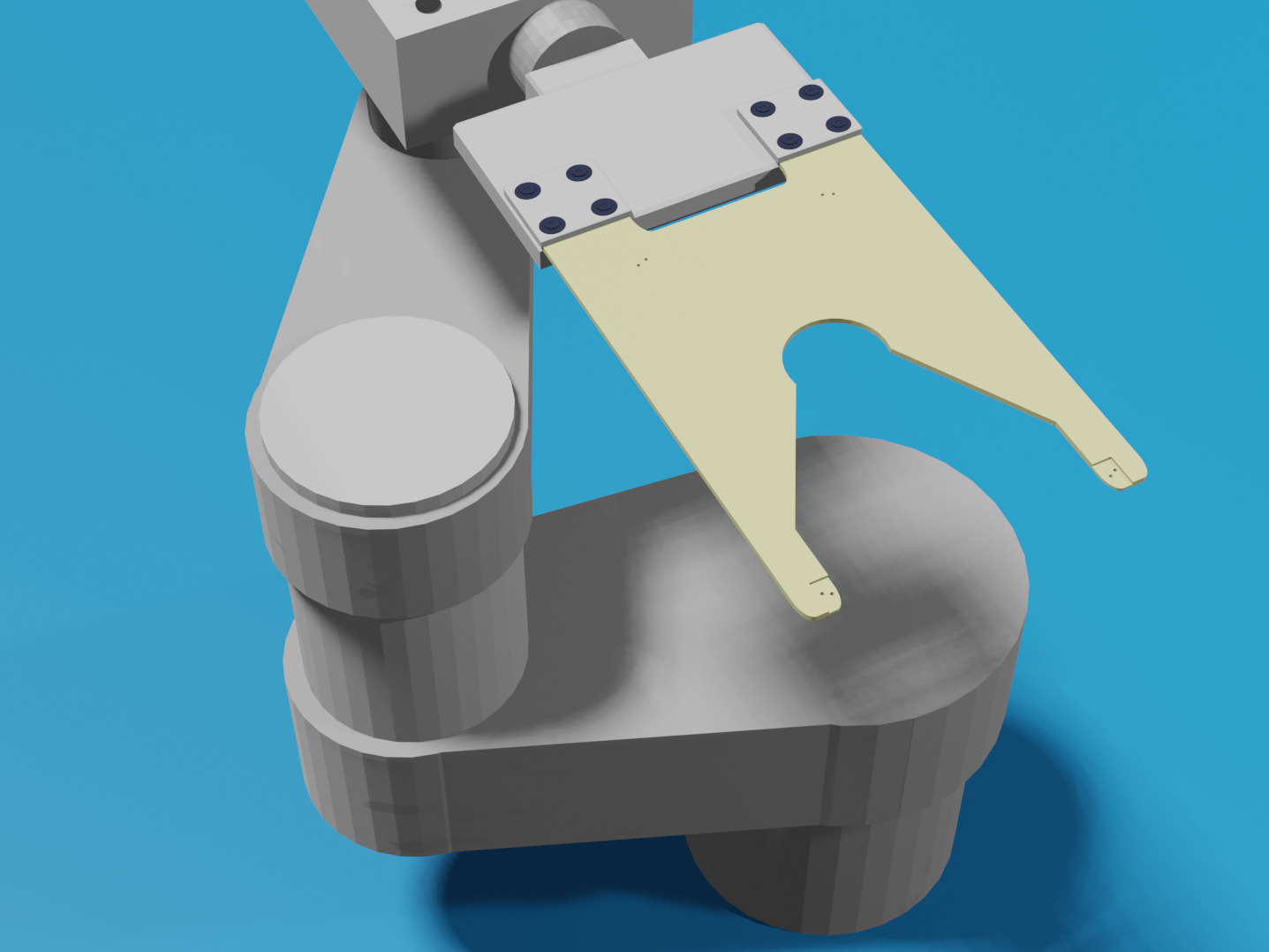

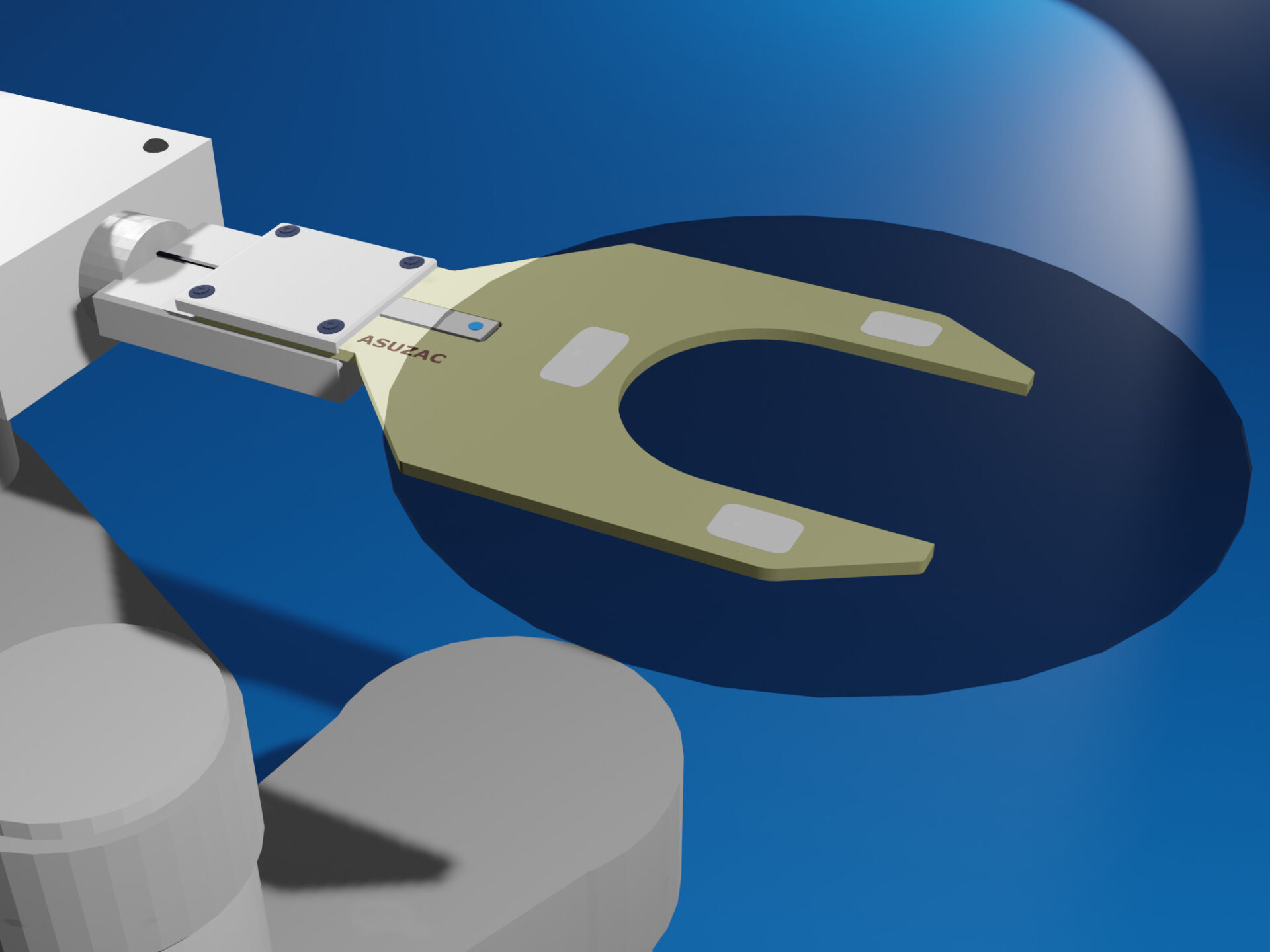

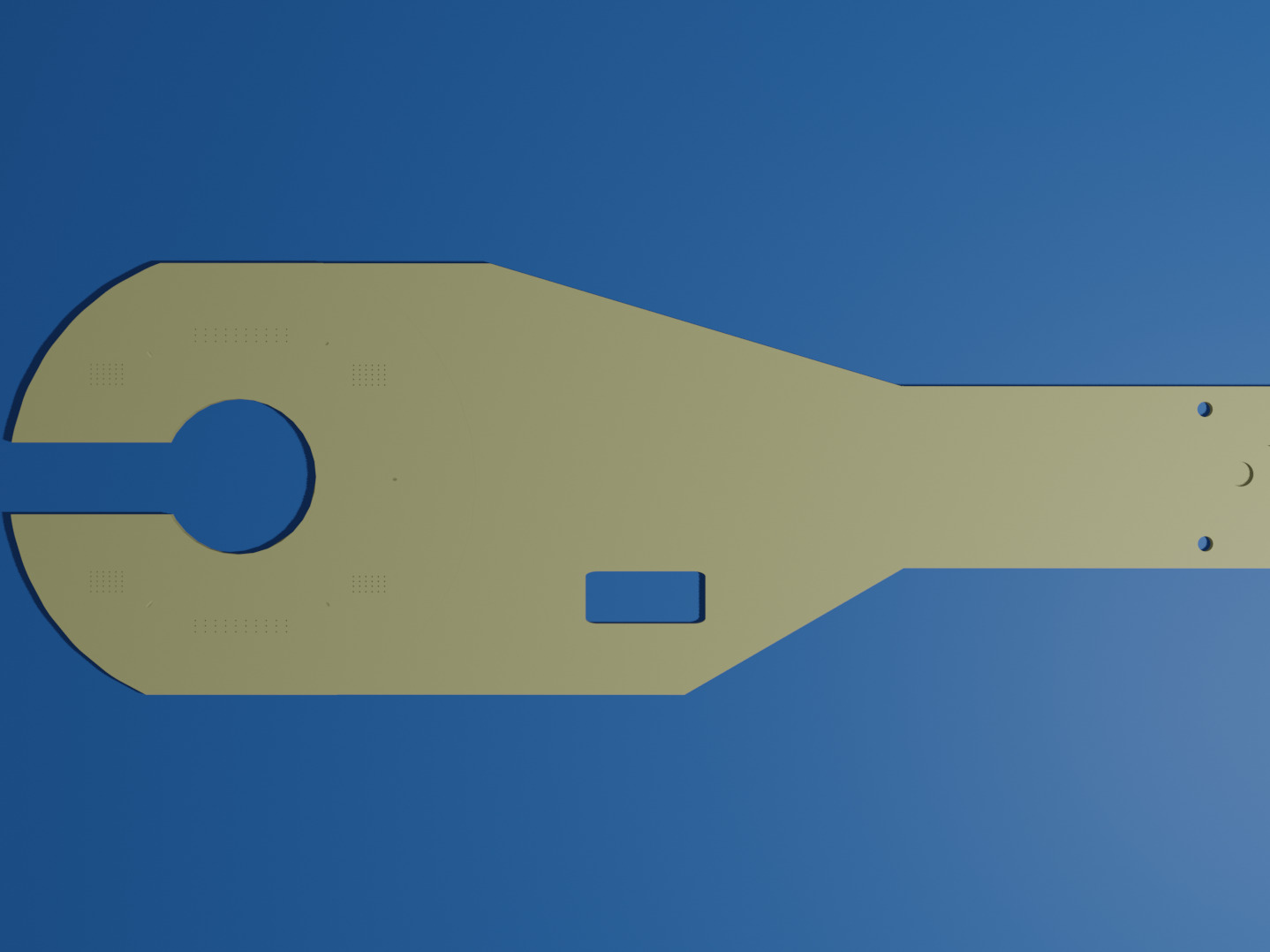

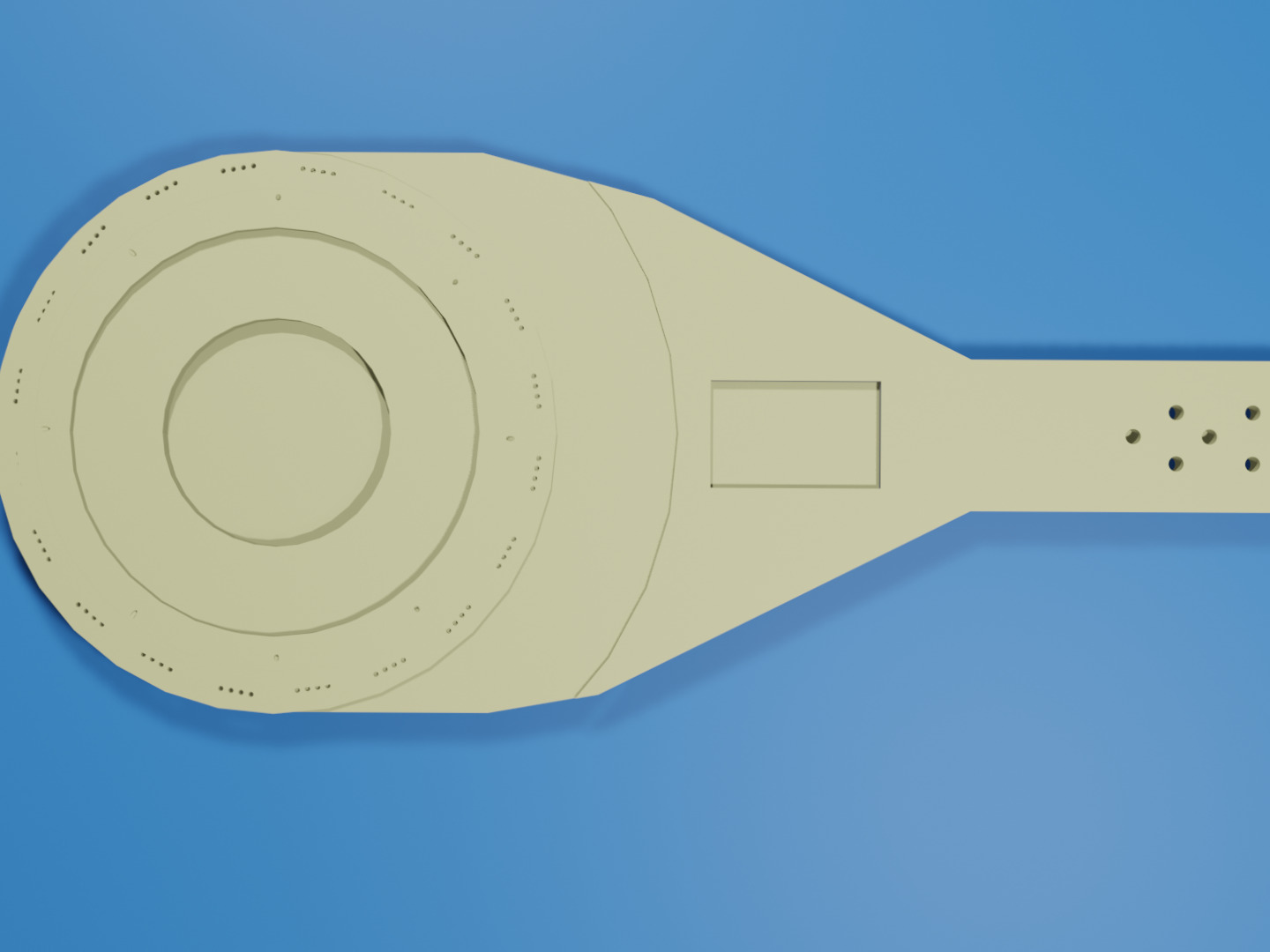

Electrostatic Diffusion Black Alumina wafer Transfer End Effector / Handling Arm |

|

Industry

|

Semiconductor

|

|

Product Type

|

Wafer transfer vacuum End Effector / Handling Arm

|

|

Material

|

Static Electricity Diffusion Alumina

High Purity Alumina

|

|

Size

|

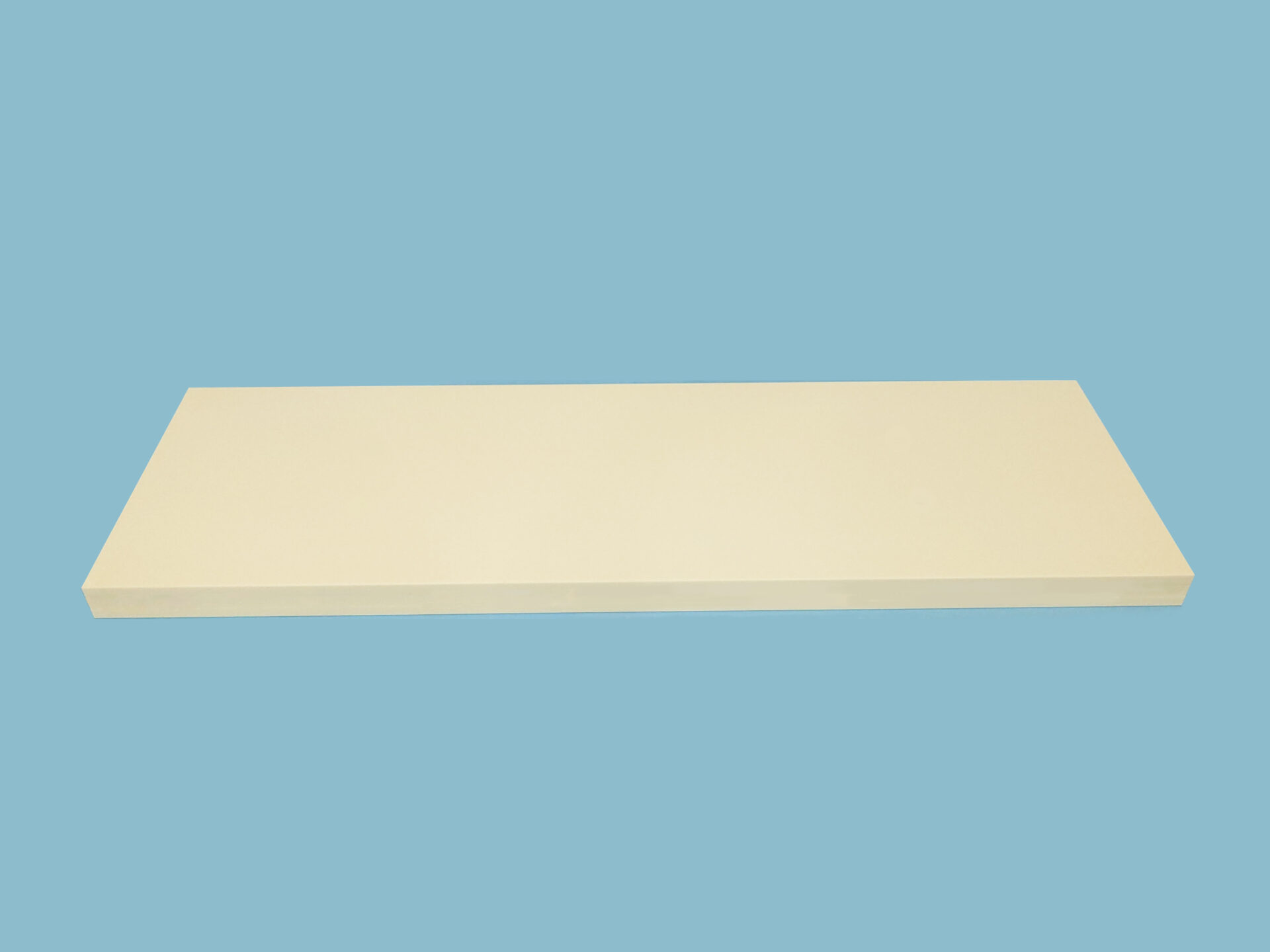

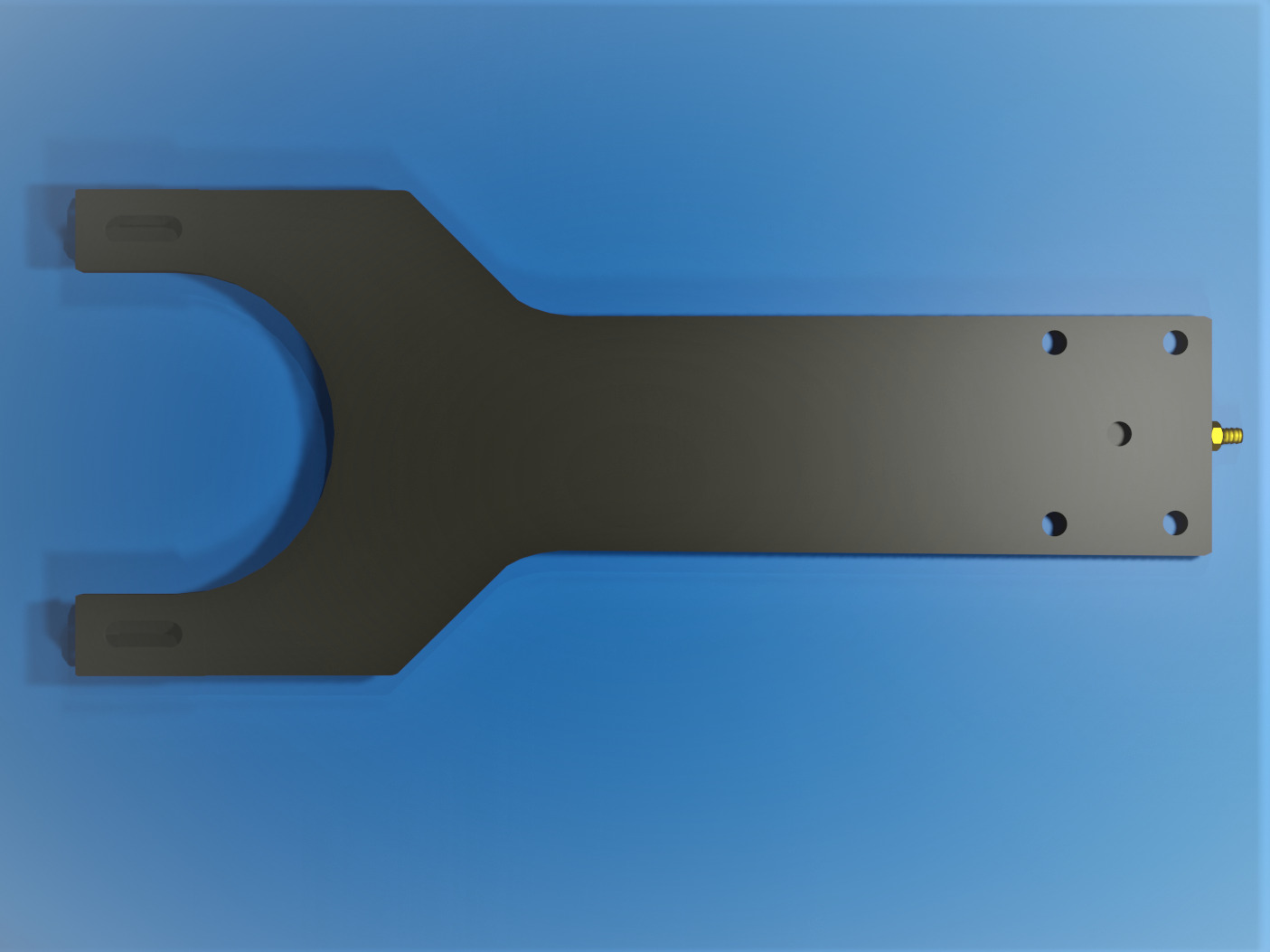

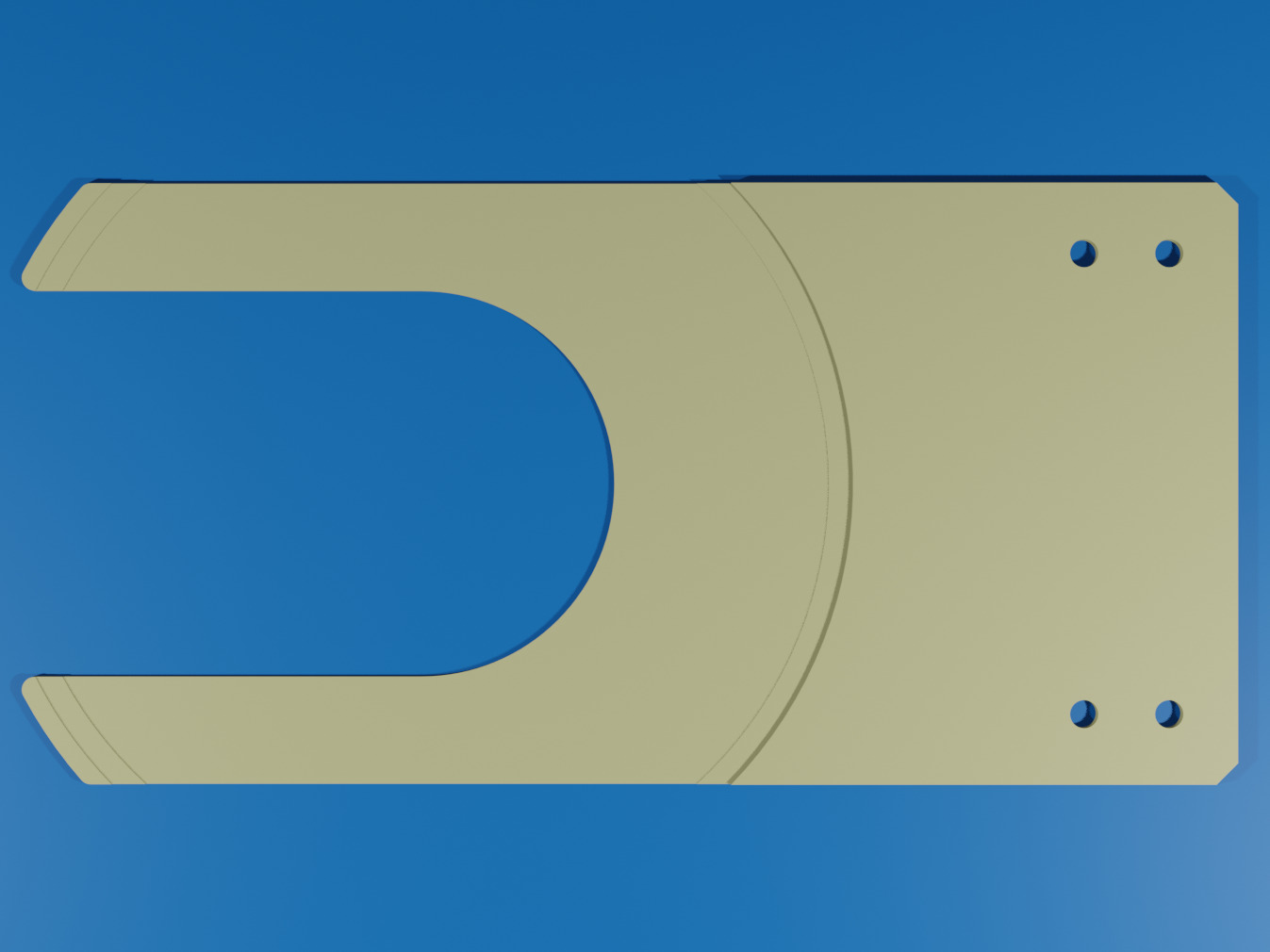

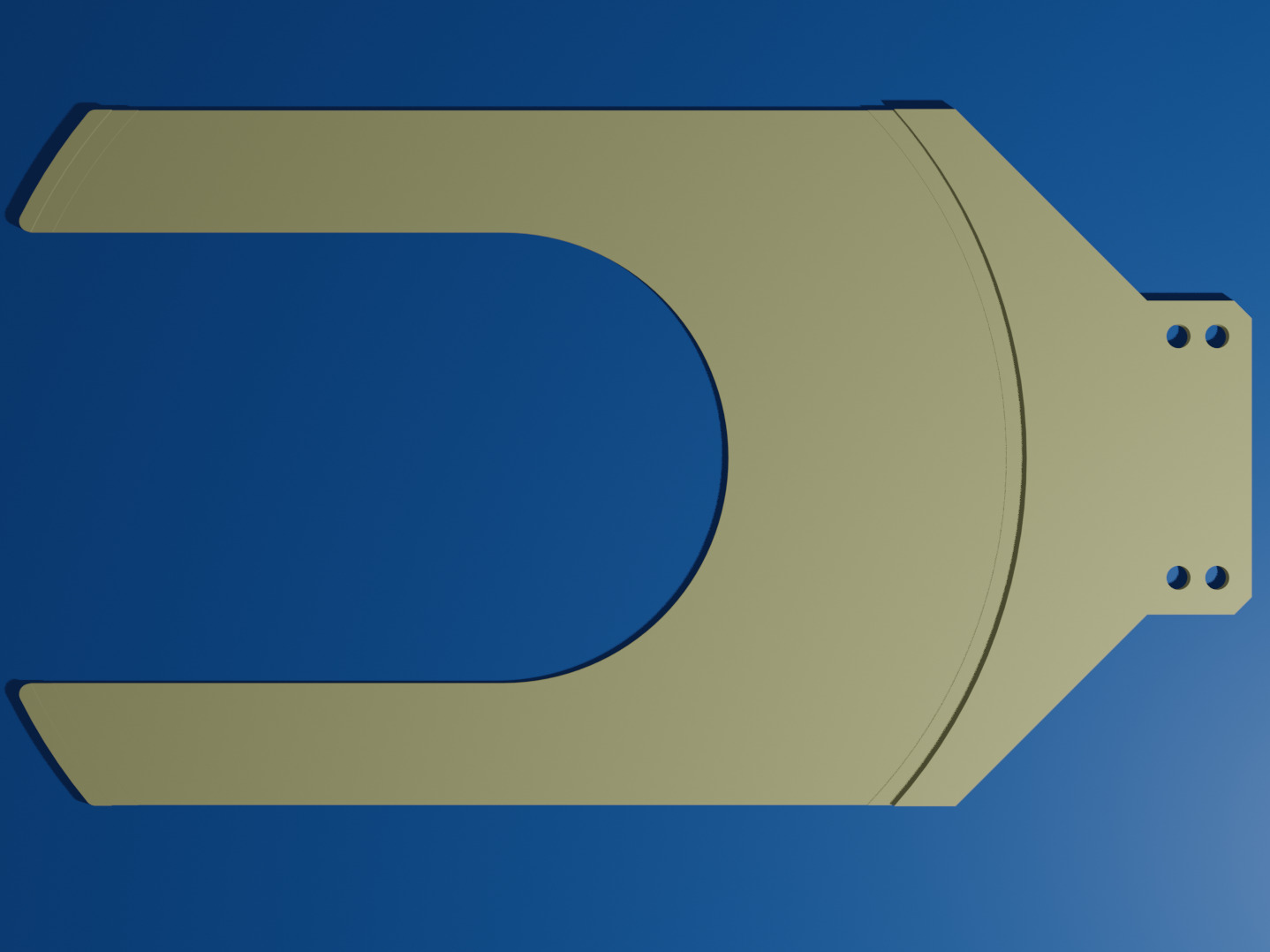

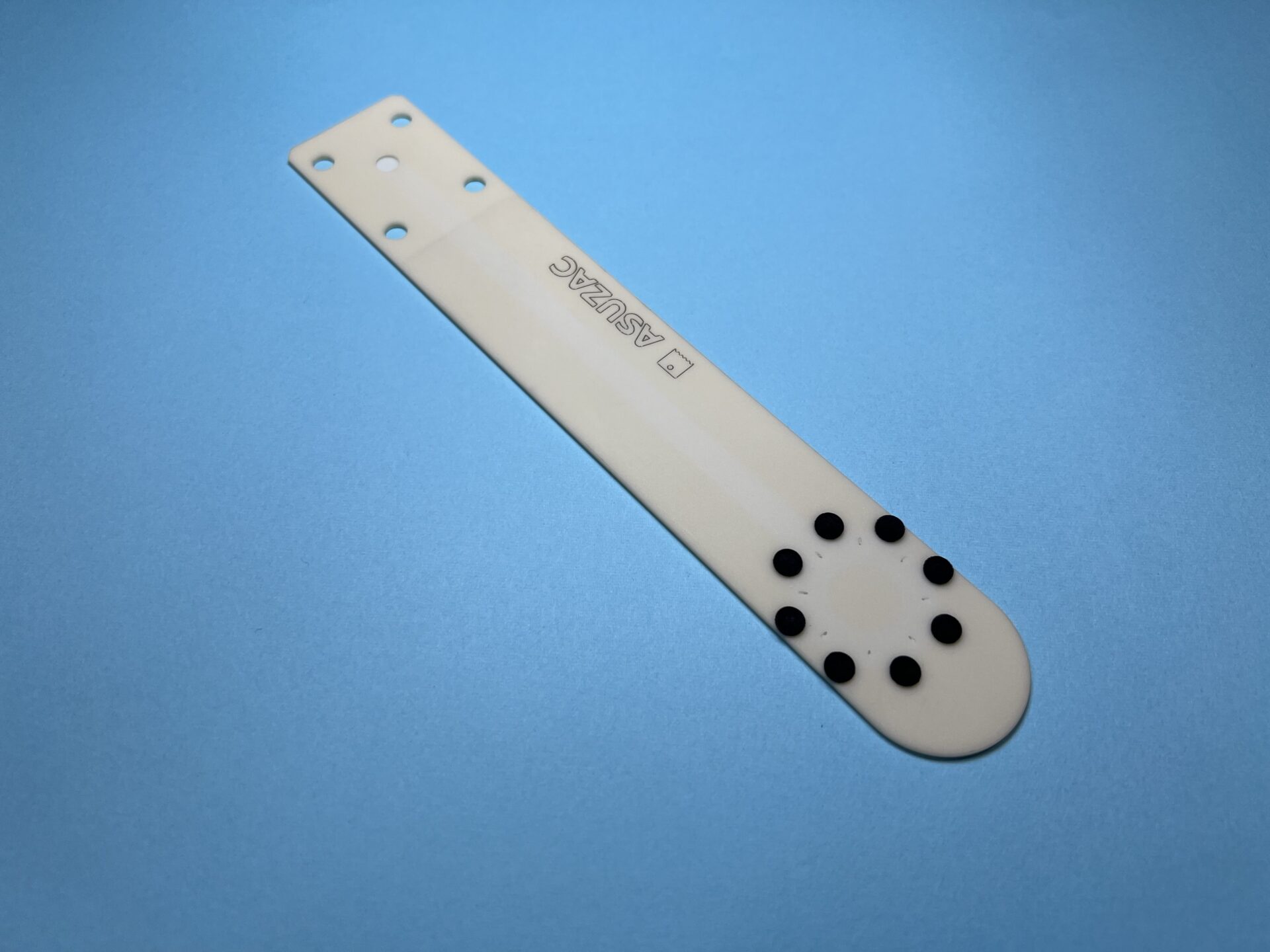

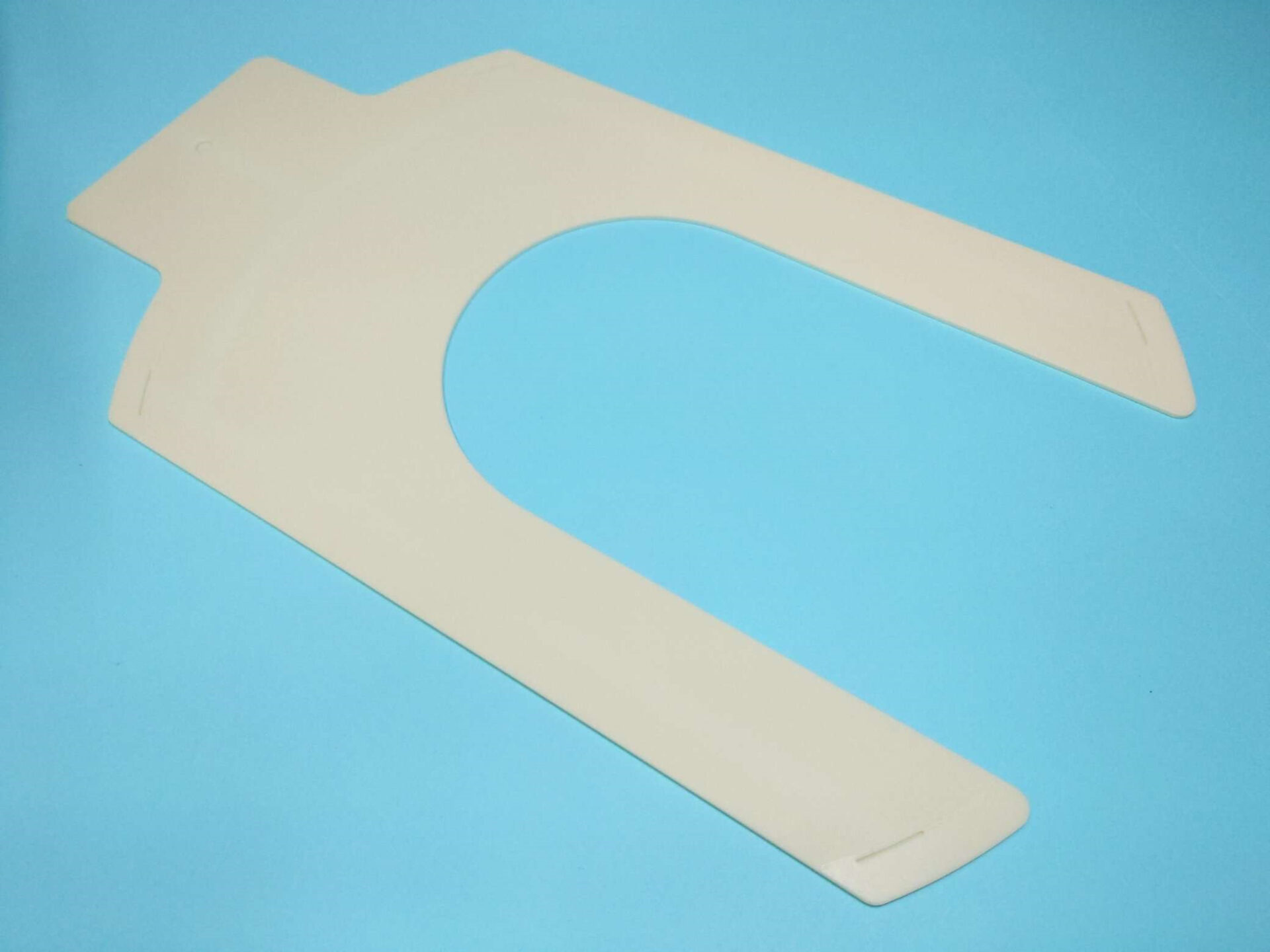

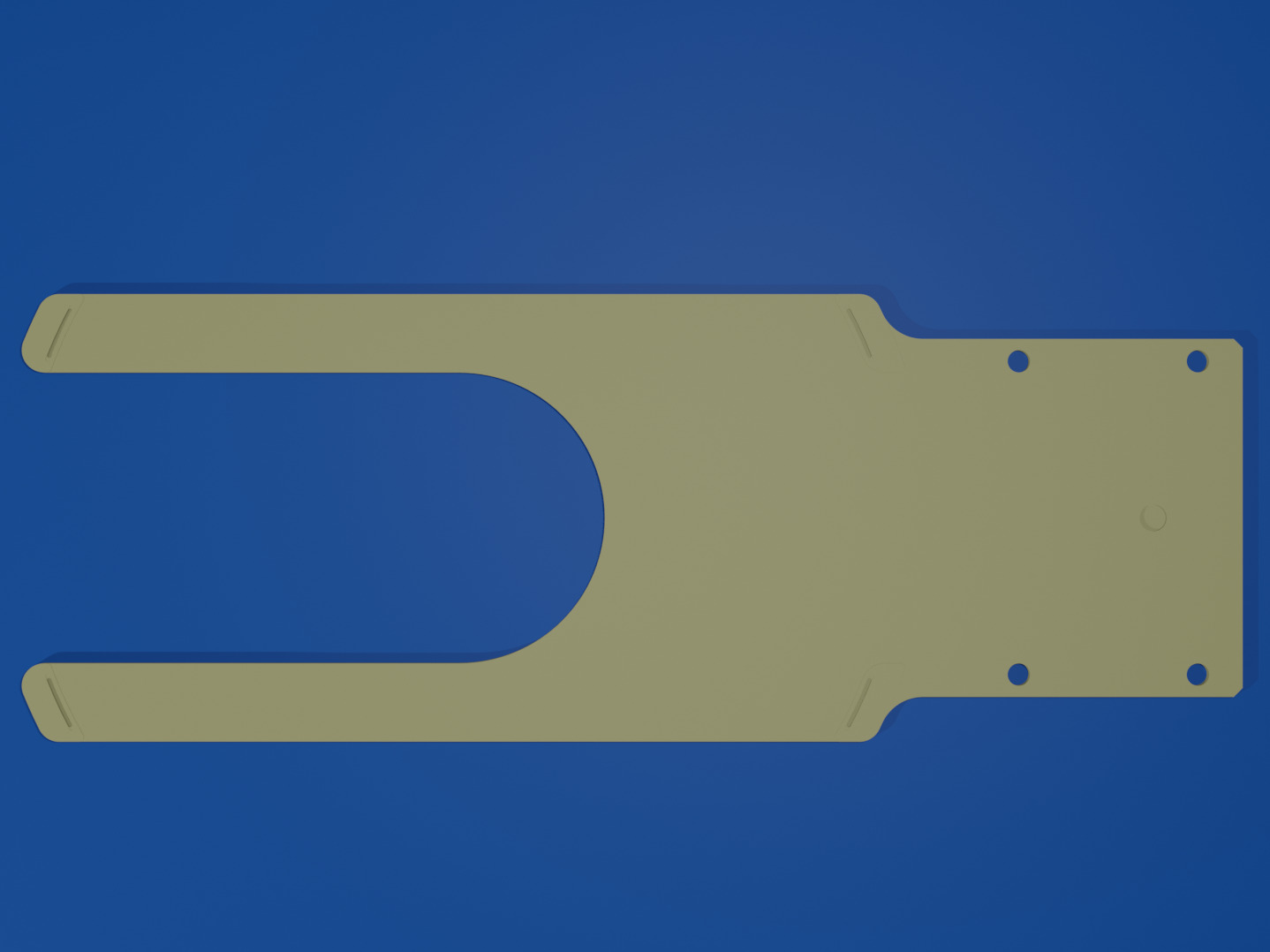

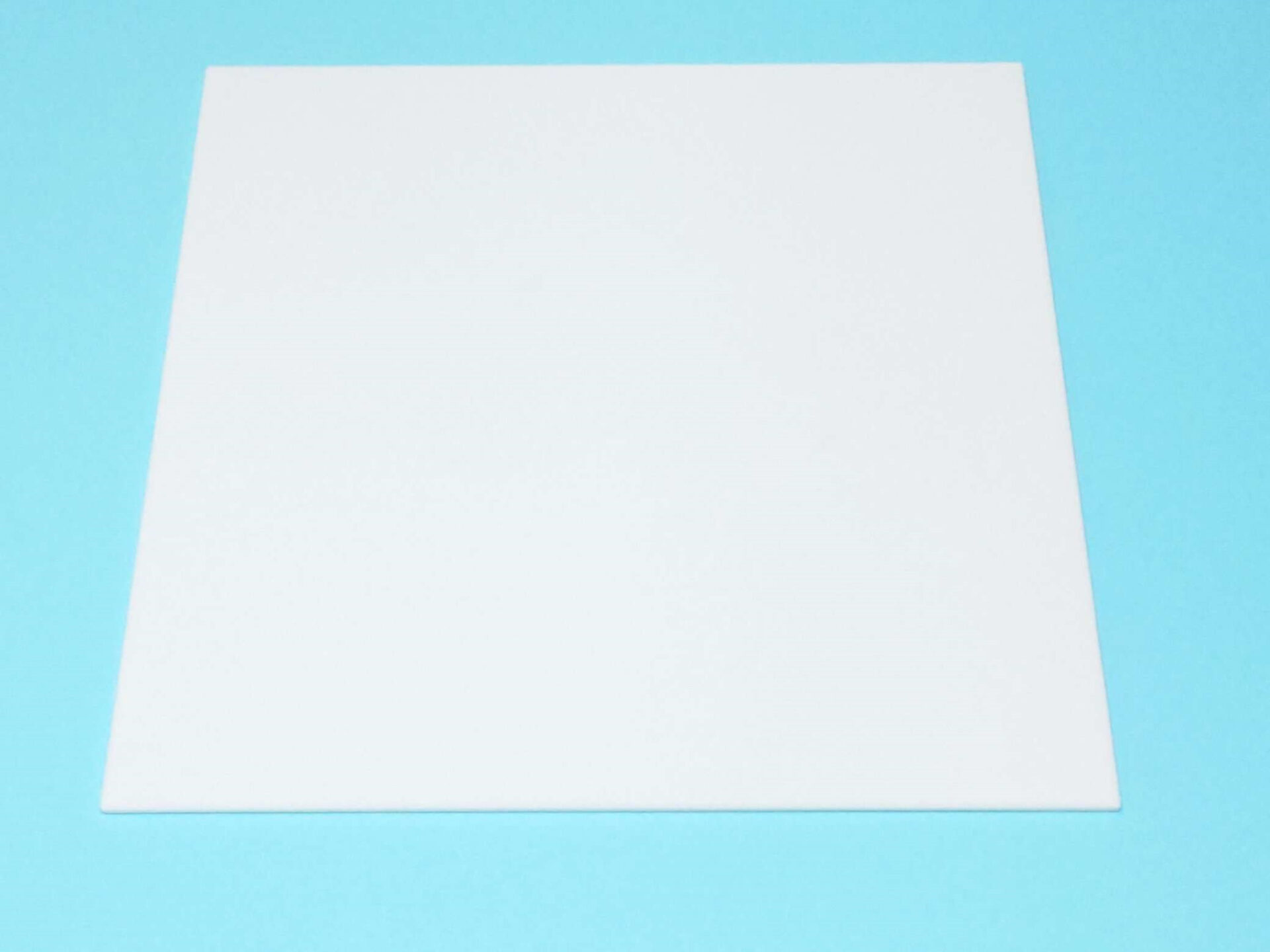

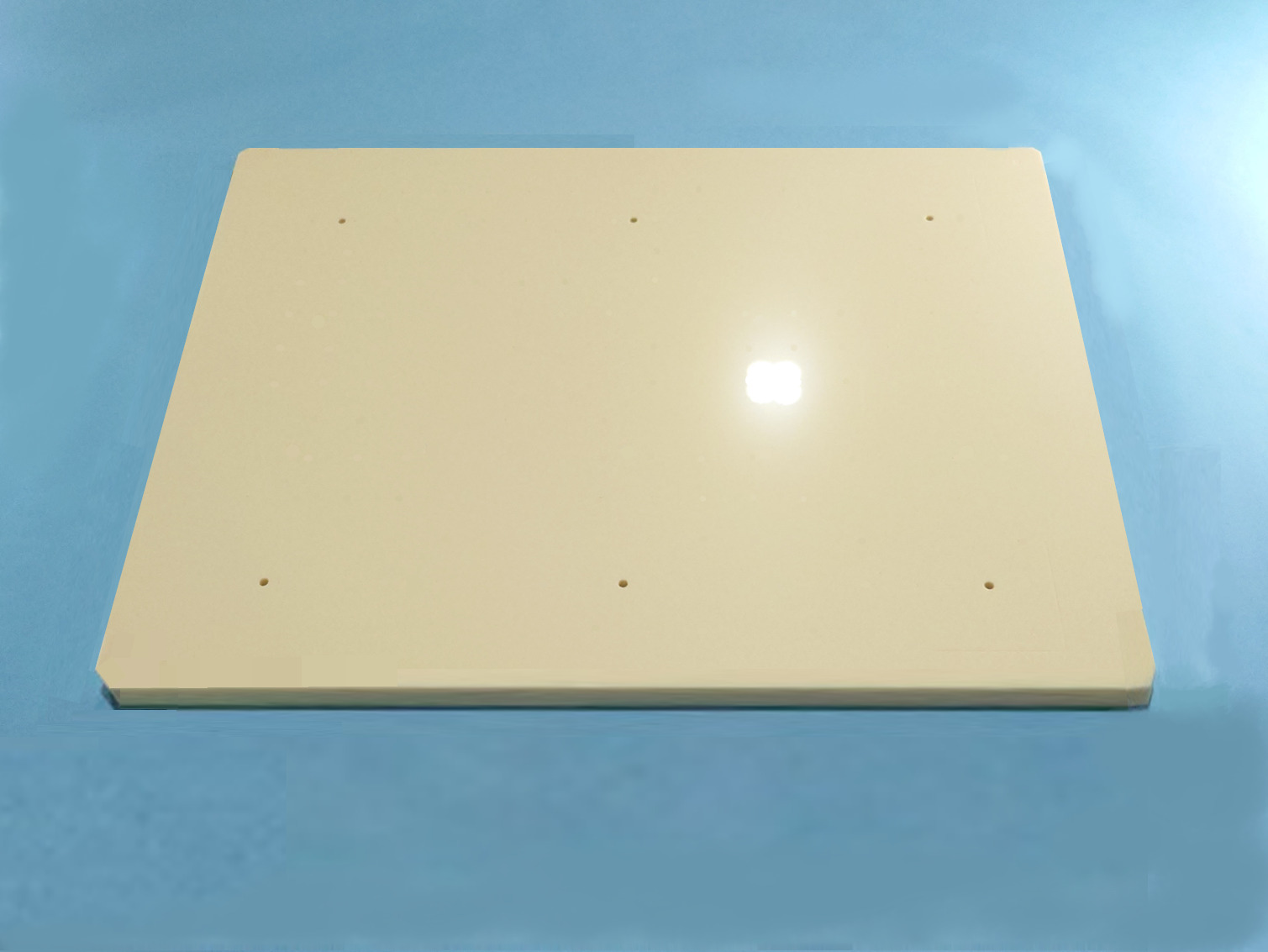

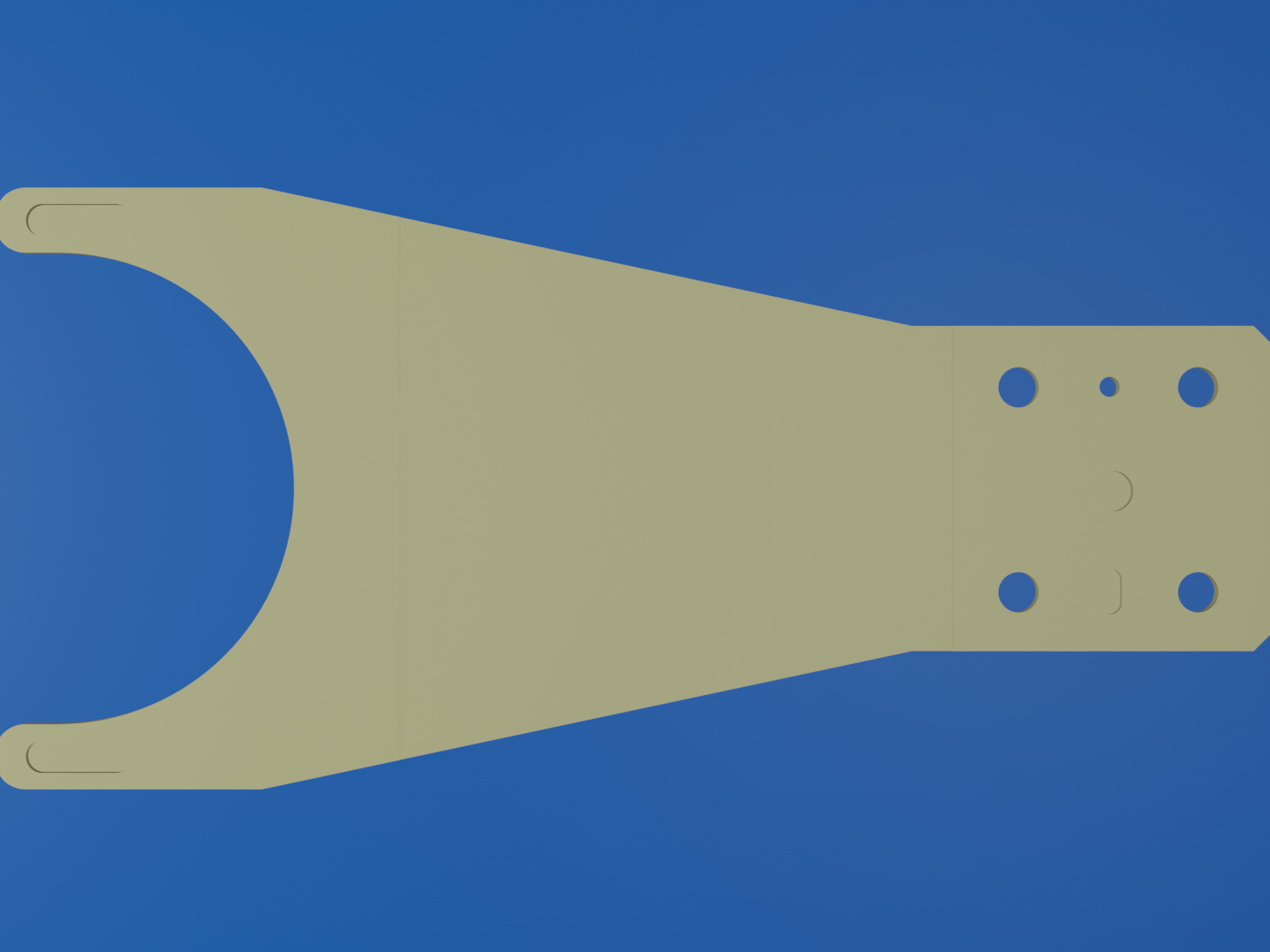

External 223.01×69.85 mm, Thickness 4.5 mm of the mounting part Thickness 2 mm at the end |

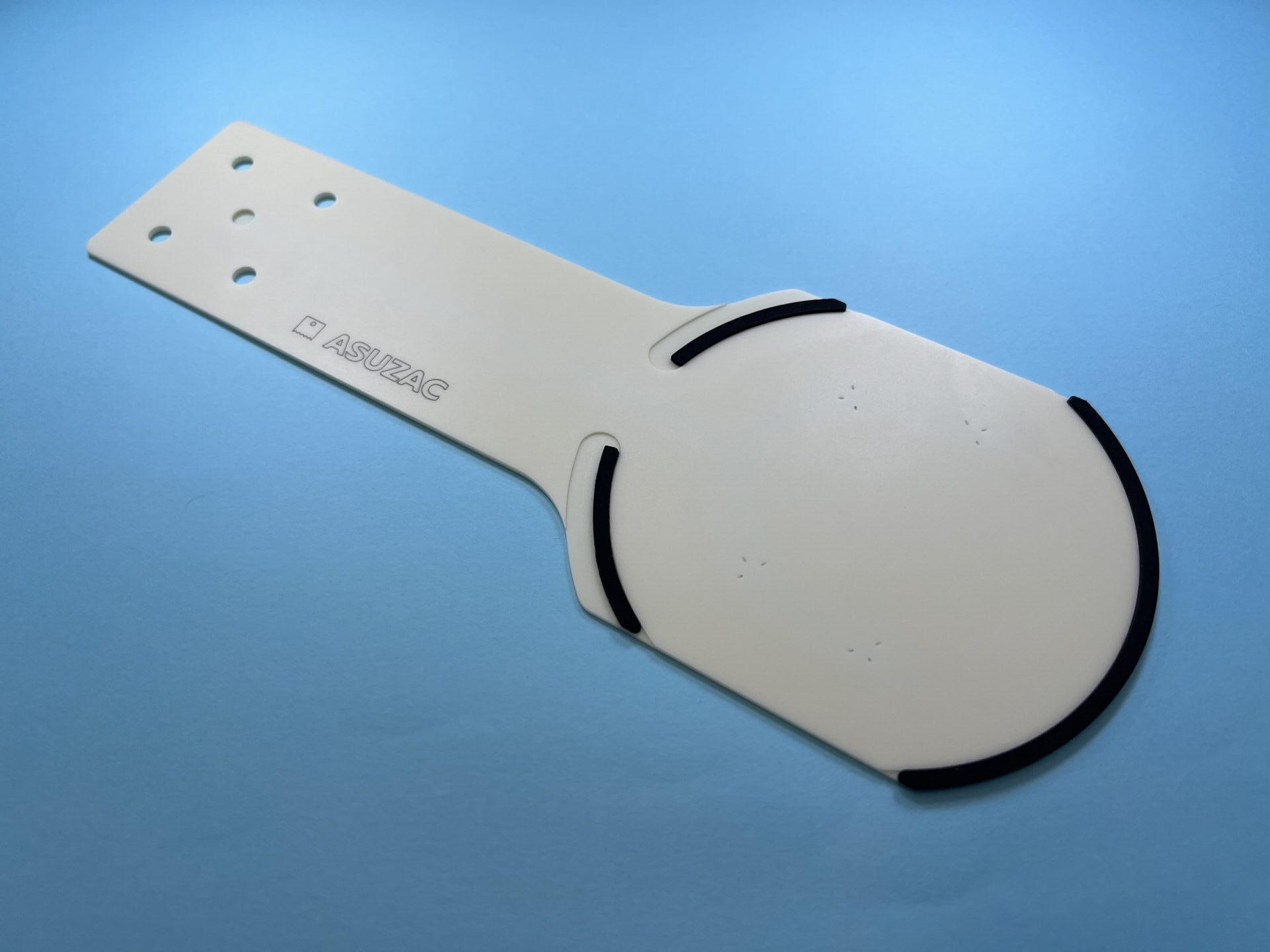

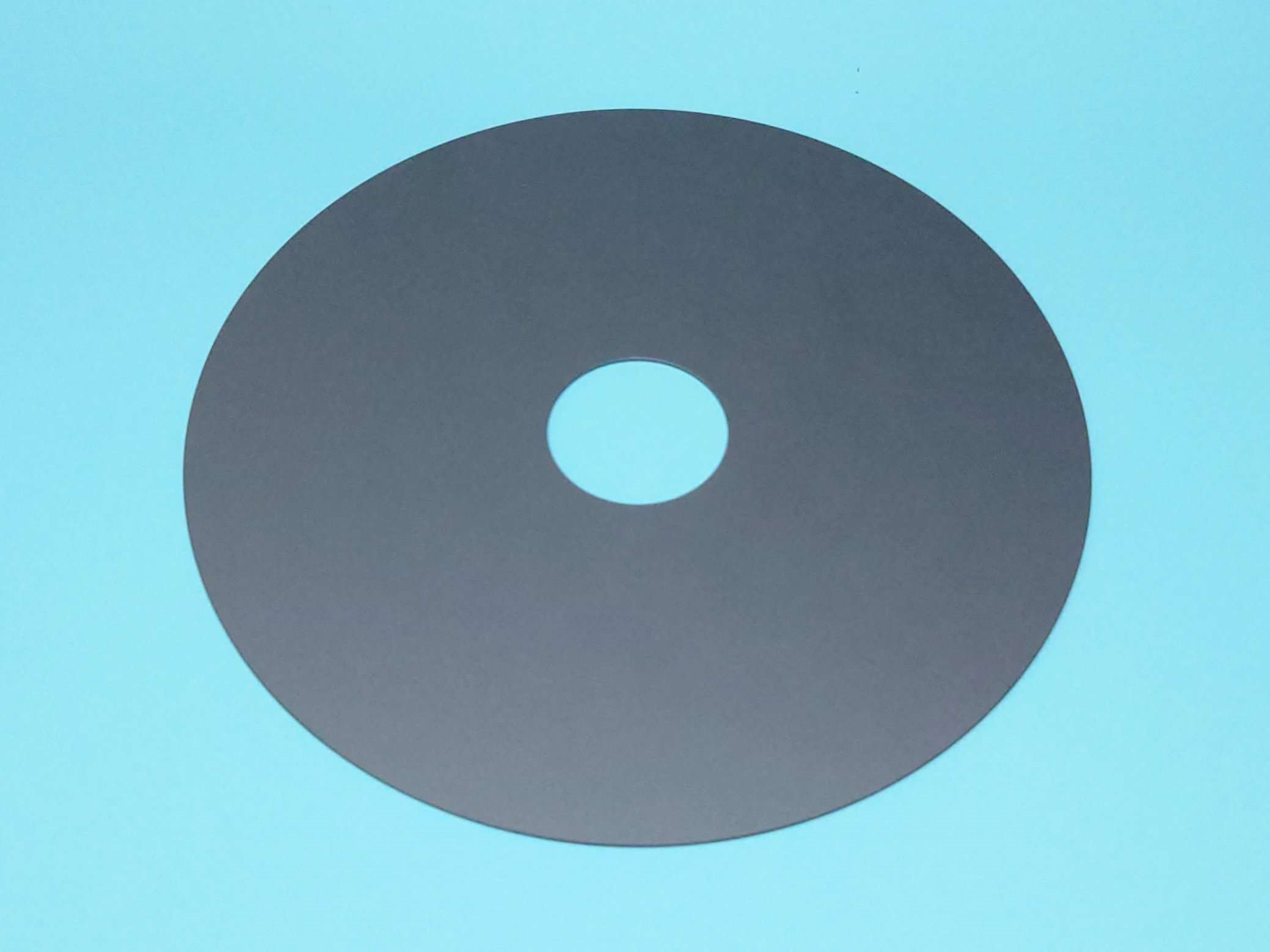

This is a wafer Transfer End Effector / Handling Arm for inspection equipment.To prevent wafer damage and warpage caused by static electricity and sparks as much as possible, the material is alumina, and an electrostatic diffusion coating with high electrostatic diffusion properties is used on the surface.

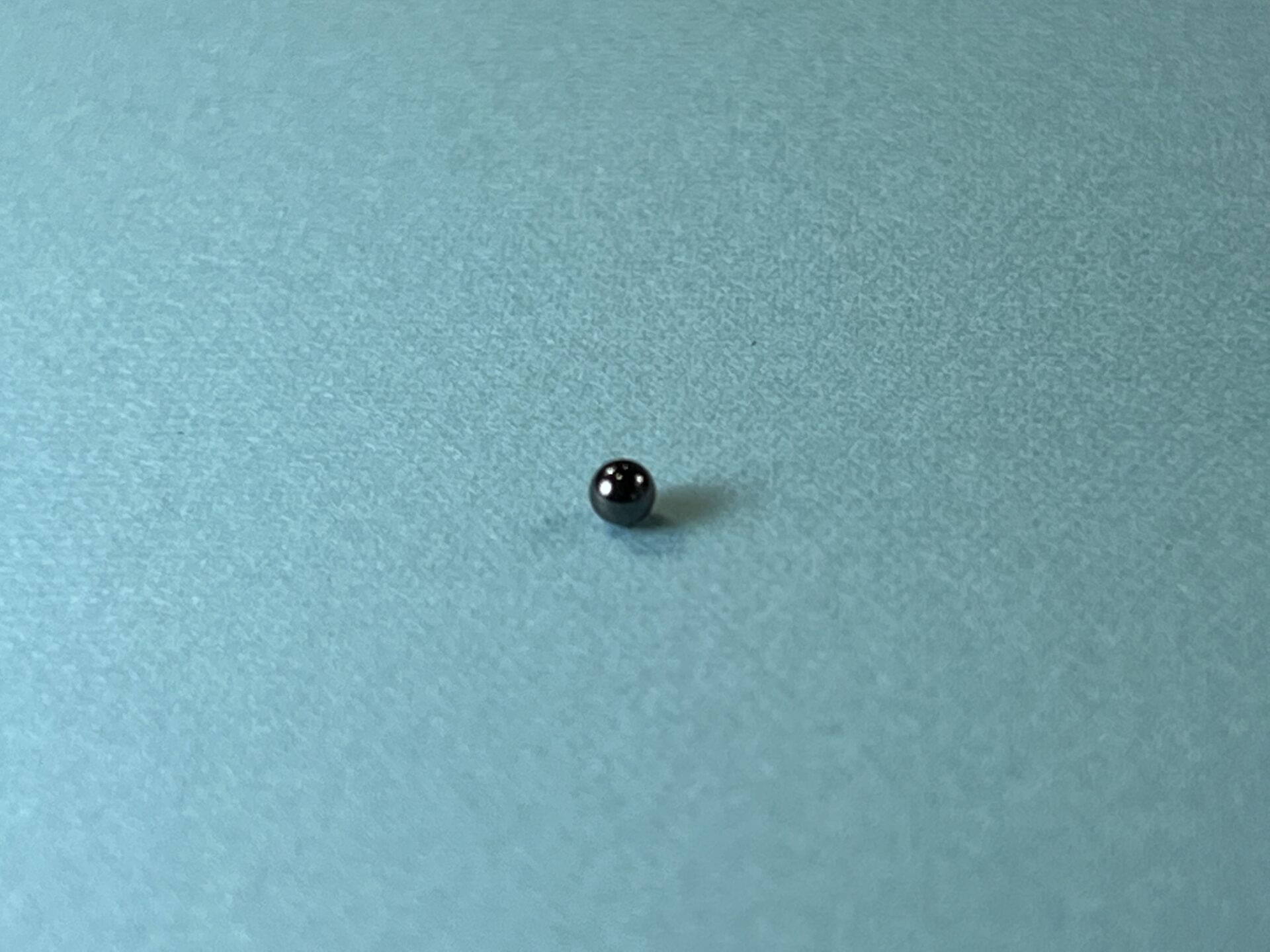

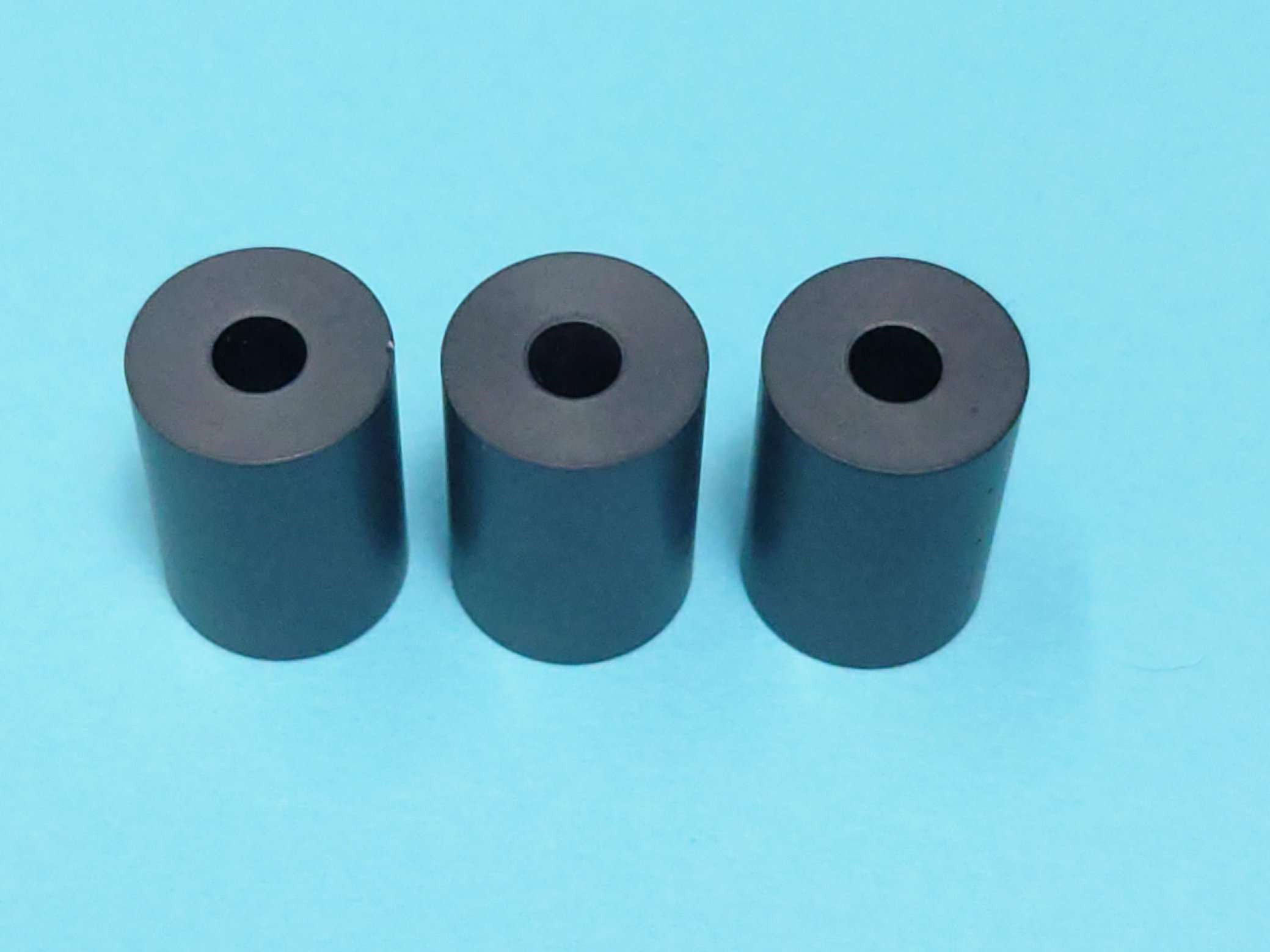

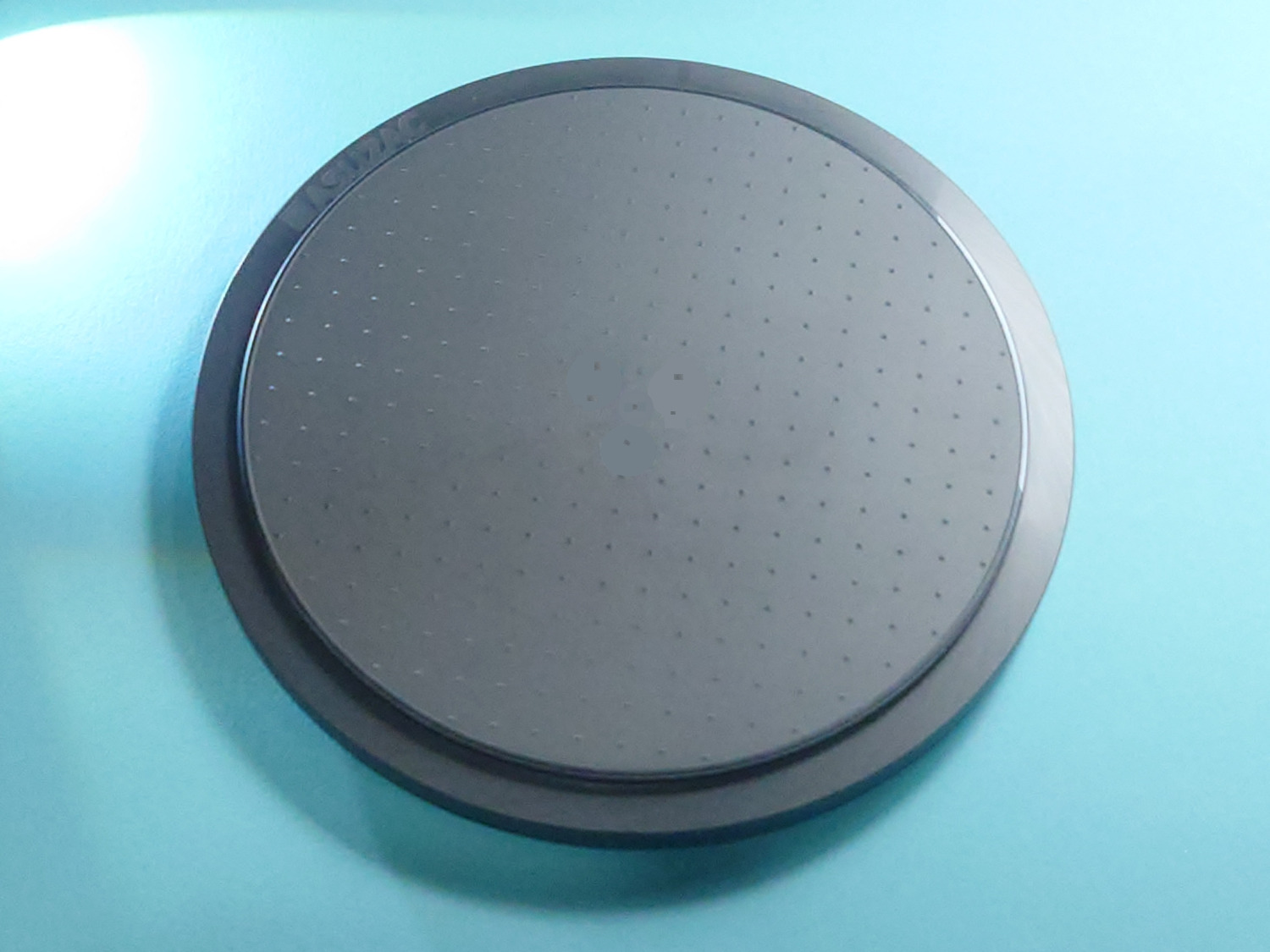

Using our machining center, counter bored holes of 4.5 mm thickness, M3, and 6.1 effective depth are made for the 0.5 mm wafer holding area. The suction boat is Φ3 with a depth of 3.3 and a surface roughness of Ra0.41.

Asuzac Corporation, which operates the Ceramics Design Lab, offers a full range of services from alumina raw material preparation, granulation, and molding to green processing (raw processing), firing, secondary processing, inspection, and cleaning.

In addition to wafer Transfer End Effector / Handling Arm such as this product, we have a large number of experience in manufacturing wafer trays, suction chucks, setters for firing, and other ceramics products. Furthermore, we handle various ceramics materials such as black alumina, electrostatic diffusion alumina, high-purity alumina including 4N, high-purity SiC, porous ceramics, conductive ceramics, and heat-resistant ceramics.

We will propose the most suitable ceramics materials according to the product application, usage environment, and required .

For the design and manufacture of ceramics products for semiconductors and electronic components, leave it to Asuzac.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

v1.jpg)

(本体アルミ、多孔質AZP60)v1.jpg)

.jpg)

(アスザックロゴ入り大きい).jpg)

.jpg)

_1.jpg)

v4.jpeg)

-v1.jpg)

外形120×80×厚み10mm-v1.jpg)

-1.jpg)

.jpg)

v1-1.jpg)

v1-1.jpg)