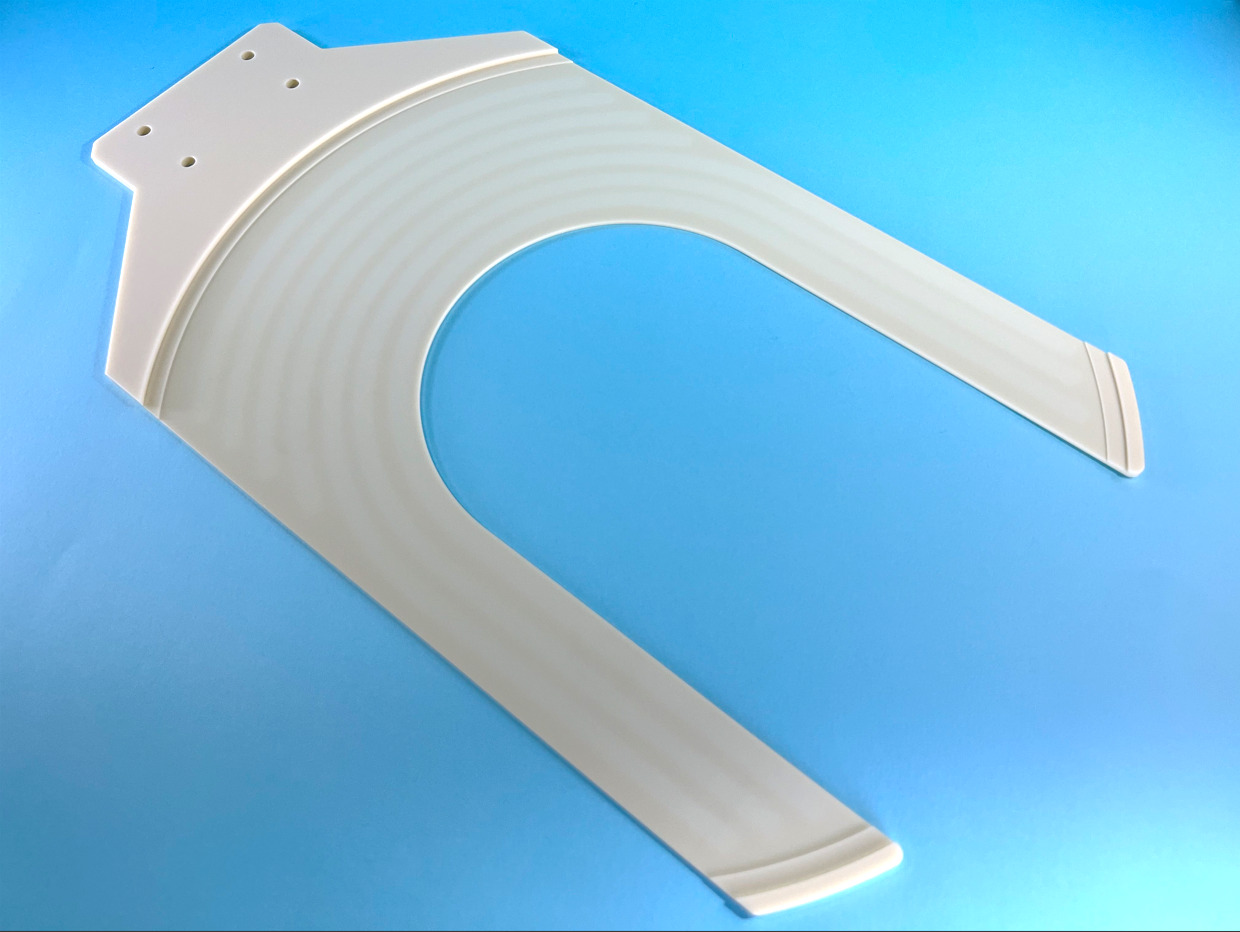

試作品UniZac-Obon®の軽量化品のご紹介

試作品のオリジナルハンドUniZac-Obon®について、内部に空洞部を複数設けることで、約10 %の軽量化に成功しまし...

Our ceramics parts are used by device manufacturers and other customers in various industries.

Cost

Cost reduction by remodeling the wafer Transfer End Effector / Handling Arm -holding section to a PAD

Product Type: Wafer Transfer End Effector / Handling ArmPAD

Proposed Effect: Man-Hour ReductionCost ReductionImproved FunctionalityImproved ProductivityWear Resistance

Suggestions for integration of suction End Effector / Handling Arm cavities

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Improved Heat ResistanceMan-Hour ReductionLong Service LifeCost ReductionOutgassing Reduction

Proposal of double-sided suction Porous Chuck

Product Type: Porous Chuck

Proposed Effect: Improved Productivity(Improved Throughput)Man-Hour ReductionCost ReductionImproved Functionality

Particles

Proposal of specially treated products that can prevent metal contamination

Product Type: Other

Proposed Effect: Improved Chemical ResistanceImproved Productivity(Improved Throughput)Man-Hour ReductionLong Service LifeMetal Contamination ControlParticle Control

Proposal of End Effector / Handling Arm for warping and thin wafer transfer

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Wafer Scratch PreventionWarped Wafer PreventionSuction Mark ReductionYield ImprovementParticle Control

Conductivity

Proposing PAD to prevent static electricity

Product Type: Wafer Transfer End Effector / Handling ArmPAD

Proposed Effect: Wafer Scratch PreventionWarped Wafer PreventionAnti-Static MeasuresReduced Defect Rate

Measures against static electricity and outgas in wafer Transfer End Effector / Handling Arm

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Improved Heat ResistanceAnti-Static MeasuresSurface Resistance ControlOutgassing Reduction

Suction Marks

Proposal of End Effector / Handling Arm for warping and thin wafer transfer

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Wafer Scratch PreventionWarped Wafer PreventionSuction Mark ReductionYield ImprovementParticle Control

パワー半導体向け薄反りウエハの保持・吸着が可能な多孔質埋め込みハンドのご提案

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Wafer Scratch PreventionSuction Mark Reduction

大型偏光フィルムの吸着が可能な500角の大型多孔質チャックのご提案

Product Type: Porous Chuck

Proposed Effect: Deformation ReductionImproved Productivity(Improved Throughput)Suction Mark Reductionワークの傷防止

Static Electricity

Proposing PAD to prevent static electricity

Product Type: Wafer Transfer End Effector / Handling ArmPAD

Proposed Effect: Wafer Scratch PreventionWarped Wafer PreventionAnti-Static MeasuresReduced Defect Rate

Cost reduction by remodeling the wafer Transfer End Effector / Handling Arm -holding section to a PAD

Product Type: Wafer Transfer End Effector / Handling ArmPAD

Proposed Effect: Man-Hour ReductionCost ReductionImproved FunctionalityImproved ProductivityWear Resistance

Proposal of a wafer Transfer End Effector / Handling Arm with superior electrostatic diffusion effect even at high temperatures

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Improved FunctionalityAnti-Static MeasuresSurface Resistance Control

Measures against static electricity and outgas in wafer Transfer End Effector / Handling Arm

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Improved Heat ResistanceAnti-Static MeasuresSurface Resistance ControlOutgassing Reduction

Reduction of defect rate of electrostatic diffusion End Effector / Handling Arm by changing coating

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Contamination MeasuresAnti-Static MeasuresSparking PreventionReduced Defect Rate

Warped Wafer

Proposing PAD to prevent static electricity

Product Type: Wafer Transfer End Effector / Handling ArmPAD

Proposed Effect: Wafer Scratch PreventionWarped Wafer PreventionAnti-Static MeasuresReduced Defect Rate

.jpg)

Proposal for a transport End Effector / Handling Arm that can suck warped wafers

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Warped Wafer PreventionMisalignment PreventionImproved Functionality

Proposal for a transport End Effector / Handling Arm that can suck warped wafers

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Warped Wafer PreventionMisalignment PreventionImproved FunctionalityYield Improvement

Proposal of a End Effector / Handling Arm with PAD that can adsorb and transport warped wafers

Product Type: Wafer Transfer End Effector / Handling ArmPAD

Proposed Effect: Warped Wafer PreventionImproved Productivity(Improved Throughput)

Productivity (Throughput)

Proposal for assembly of the sensor to the wafer Transfer End Effector / Handling Arm

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Improved Productivity(Improved Throughput)Improved Functionality

Proposing solutions for resin products that are worn and troublesome by using ceramics

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Wear Resistance ImprovementImproved Productivity(Improved Throughput)Man-Hour ReductionCost Reduction

Suggestions for integration of suction End Effector / Handling Arm cavities

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Improved Heat ResistanceMan-Hour ReductionLong Service LifeCost ReductionOutgassing Reduction

Wafer Scratching

Proposal for a transport End Effector / Handling Arm that can suck warped wafers

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Warped Wafer PreventionMisalignment PreventionImproved FunctionalityYield Improvement

Proposal of End Effector / Handling Arm for warping and thin wafer transfer

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Wafer Scratch PreventionWarped Wafer PreventionSuction Mark ReductionYield ImprovementParticle Control

Proposing PAD surface-treatment to prevent problems with wafer sticking

Product Type: Wafer Transfer End Effector / Handling ArmPAD

Proposed Effect: Wafer Scratch PreventionMisalignment PreventionContact Damage ReductionYield Improvement

パワー半導体向け薄反りウエハの保持・吸着が可能な多孔質埋め込みハンドのご提案

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Wafer Scratch PreventionSuction Mark Reduction

Part Replacement Time

Proposal for a Transfer End Effector / Handling Arm that can use one wafer for adsorption and floating

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Man-Hour ReductionCost ReductionImproved FunctionalityImproved Productivity

Cost reduction by remodeling the wafer Transfer End Effector / Handling Arm -holding section to a PAD

Product Type: Wafer Transfer End Effector / Handling ArmPAD

Proposed Effect: Man-Hour ReductionCost ReductionImproved FunctionalityImproved ProductivityWear Resistance

Alumina-protective cover reduces the frequency of replacement of heater components for CVD equipment

Product Type: Alumina Cover

Proposed Effect: Man-Hour ReductionCost ReductionImproved Productivity

Proposal for assembly of the sensor to the wafer Transfer End Effector / Handling Arm

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Improved Productivity(Improved Throughput)Improved Functionality

Proposing solutions for resin products that are worn and troublesome by using ceramics

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Wear Resistance ImprovementImproved Productivity(Improved Throughput)Man-Hour ReductionCost Reduction

Proposal of double-sided suction Porous Chuck

Product Type: Porous Chuck

Proposed Effect: Improved Productivity(Improved Throughput)Man-Hour ReductionCost ReductionImproved Functionality

Wafer Sticking

Proposing PAD surface-treatment to prevent problems with wafer sticking

Product Type: Wafer Transfer End Effector / Handling ArmPAD

Proposed Effect: Wafer Scratch PreventionMisalignment PreventionContact Damage ReductionYield Improvement

パワー半導体向け薄反りウエハの保持・吸着が可能な多孔質埋め込みハンドのご提案

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Wafer Scratch PreventionSuction Mark Reduction

Air-Permeability

Proposal of a porous setter with low impact on the work piece and good air permeability

Product Type: Baking Setter

Proposed Effect: Contact Damage ReductionImproved FunctionalityReduced Defect RateYield Improvement

パワー半導体向け薄反りウエハの保持・吸着が可能な多孔質埋め込みハンドのご提案

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Wafer Scratch PreventionSuction Mark Reduction

Misalignment

Proposal for a transport End Effector / Handling Arm that can suck warped wafers

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Warped Wafer PreventionMisalignment PreventionImproved FunctionalityYield Improvement

Proposing PAD surface-treatment to prevent problems with wafer sticking

Product Type: Wafer Transfer End Effector / Handling ArmPAD

Proposed Effect: Wafer Scratch PreventionMisalignment PreventionContact Damage ReductionYield Improvement

Plasma Resistance

Yield

Proposal of a porous setter with low impact on the work piece and good air permeability

Product Type: Baking Setter

Proposed Effect: Contact Damage ReductionImproved FunctionalityReduced Defect RateYield Improvement

大型偏光フィルムの吸着が可能な500角の大型多孔質チャックのご提案

Product Type: Porous Chuck

Proposed Effect: Deformation ReductionImproved Productivity(Improved Throughput)Suction Mark Reductionワークの傷防止

Contact Damage

Reduction of contact damage by changing the material of the wafer Transfer End Effector / Handling Arm from metal to conductive ceramics

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Contact Damage ReductionWear PreventionContamination Measures

Proposal of a porous setter with low impact on the work piece and good air permeability

Product Type: Baking Setter

Proposed Effect: Contact Damage ReductionImproved FunctionalityReduced Defect RateYield Improvement

Proposing PAD surface-treatment to prevent problems with wafer sticking

Product Type: Wafer Transfer End Effector / Handling ArmPAD

Proposed Effect: Wafer Scratch PreventionMisalignment PreventionContact Damage ReductionYield Improvement

Product Life

Proposal of specially treated products that can prevent metal contamination

Product Type: Other

Proposed Effect: Improved Chemical ResistanceImproved Productivity(Improved Throughput)Man-Hour ReductionLong Service LifeMetal Contamination ControlParticle Control

Suggestions for integration of suction End Effector / Handling Arm cavities

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Improved Heat ResistanceMan-Hour ReductionLong Service LifeCost ReductionOutgassing Reduction

Dust Emissions

Reduction of contact damage by changing the material of the wafer Transfer End Effector / Handling Arm from metal to conductive ceramics

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Contact Damage ReductionWear PreventionContamination Measures

Proposal of specially treated products that can prevent metal contamination

Product Type: Other

Proposed Effect: Improved Chemical ResistanceImproved Productivity(Improved Throughput)Man-Hour ReductionLong Service LifeMetal Contamination ControlParticle Control

Heat Resistance

Proposal of a wafer Transfer End Effector / Handling Arm with superior electrostatic diffusion effect even at high temperatures

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Improved FunctionalityAnti-Static MeasuresSurface Resistance Control

Measures against static electricity and outgas in wafer Transfer End Effector / Handling Arm

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Improved Heat ResistanceAnti-Static MeasuresSurface Resistance ControlOutgassing Reduction

Material change to Black Alumina pin

Product Type: Other

Proposed Effect: Wear Resistance ImprovementImproved Heat ResistanceImproved Plasma Resistance

Abrasion

Reduction of contact damage by changing the material of the wafer Transfer End Effector / Handling Arm from metal to conductive ceramics

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Contact Damage ReductionWear PreventionContamination Measures

Cost reduction by remodeling the wafer Transfer End Effector / Handling Arm -holding section to a PAD

Product Type: Wafer Transfer End Effector / Handling ArmPAD

Proposed Effect: Man-Hour ReductionCost ReductionImproved FunctionalityImproved ProductivityWear Resistance

Proposing solutions for resin products that are worn and troublesome by using ceramics

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Wear Resistance ImprovementImproved Productivity(Improved Throughput)Man-Hour ReductionCost Reduction

Functionality

Proposal for a portable wafer Transfer End Effector / Handling Arm

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Improved FunctionalityPortability

Proposal for a Transfer End Effector / Handling Arm that can use one wafer for adsorption and floating

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Man-Hour ReductionCost ReductionImproved FunctionalityImproved Productivity

薄ウェハ

Wear Resistance Improvement

Proposing solutions for resin products that are worn and troublesome by using ceramics

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Wear Resistance ImprovementImproved Productivity(Improved Throughput)Man-Hour ReductionCost Reduction

Material change to Black Alumina pin

Product Type: Other

Proposed Effect: Wear Resistance ImprovementImproved Heat ResistanceImproved Plasma Resistance

Improved Functionality

.jpg)

Proposal for a transport End Effector / Handling Arm that can suck warped wafers

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Warped Wafer PreventionMisalignment PreventionImproved Functionality

Proposal for a transport End Effector / Handling Arm that can suck warped wafers

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Warped Wafer PreventionMisalignment PreventionImproved FunctionalityYield Improvement

Proposal for a portable wafer Transfer End Effector / Handling Arm

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Improved FunctionalityPortability

Proposal for a Transfer End Effector / Handling Arm that can use one wafer for adsorption and floating

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Man-Hour ReductionCost ReductionImproved FunctionalityImproved Productivity

Cost reduction by remodeling the wafer Transfer End Effector / Handling Arm -holding section to a PAD

Product Type: Wafer Transfer End Effector / Handling ArmPAD

Proposed Effect: Man-Hour ReductionCost ReductionImproved FunctionalityImproved ProductivityWear Resistance

Proposal of a porous setter with low impact on the work piece and good air permeability

Product Type: Baking Setter

Proposed Effect: Contact Damage ReductionImproved FunctionalityReduced Defect RateYield Improvement

Proposal of a wafer Transfer End Effector / Handling Arm with superior electrostatic diffusion effect even at high temperatures

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Improved FunctionalityAnti-Static MeasuresSurface Resistance Control

Proposal for assembly of the sensor to the wafer Transfer End Effector / Handling Arm

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Improved Productivity(Improved Throughput)Improved Functionality

Proposal of double-sided suction Porous Chuck

Product Type: Porous Chuck

Proposed Effect: Improved Productivity(Improved Throughput)Man-Hour ReductionCost ReductionImproved Functionality

Wafer Scratch Prevention

Proposing PAD to prevent static electricity

Product Type: Wafer Transfer End Effector / Handling ArmPAD

Proposed Effect: Wafer Scratch PreventionWarped Wafer PreventionAnti-Static MeasuresReduced Defect Rate

Proposal of End Effector / Handling Arm for warping and thin wafer transfer

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Wafer Scratch PreventionWarped Wafer PreventionSuction Mark ReductionYield ImprovementParticle Control

Proposing PAD surface-treatment to prevent problems with wafer sticking

Product Type: Wafer Transfer End Effector / Handling ArmPAD

Proposed Effect: Wafer Scratch PreventionMisalignment PreventionContact Damage ReductionYield Improvement

パワー半導体向け薄反りウエハの保持・吸着が可能な多孔質埋め込みハンドのご提案

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Wafer Scratch PreventionSuction Mark Reduction

Anti-Static Measures

Proposing PAD to prevent static electricity

Product Type: Wafer Transfer End Effector / Handling ArmPAD

Proposed Effect: Wafer Scratch PreventionWarped Wafer PreventionAnti-Static MeasuresReduced Defect Rate

Proposal of a wafer Transfer End Effector / Handling Arm with superior electrostatic diffusion effect even at high temperatures

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Improved FunctionalityAnti-Static MeasuresSurface Resistance Control

Measures against static electricity and outgas in wafer Transfer End Effector / Handling Arm

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Improved Heat ResistanceAnti-Static MeasuresSurface Resistance ControlOutgassing Reduction

Reduction of defect rate of electrostatic diffusion End Effector / Handling Arm by changing coating

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Contamination MeasuresAnti-Static MeasuresSparking PreventionReduced Defect Rate

Improved Heat Resistance

Measures against static electricity and outgas in wafer Transfer End Effector / Handling Arm

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Improved Heat ResistanceAnti-Static MeasuresSurface Resistance ControlOutgassing Reduction

Suggestions for integration of suction End Effector / Handling Arm cavities

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Improved Heat ResistanceMan-Hour ReductionLong Service LifeCost ReductionOutgassing Reduction

Material change to Black Alumina pin

Product Type: Other

Proposed Effect: Wear Resistance ImprovementImproved Heat ResistanceImproved Plasma Resistance

Warped Wafer Prevention

Proposing PAD to prevent static electricity

Product Type: Wafer Transfer End Effector / Handling ArmPAD

Proposed Effect: Wafer Scratch PreventionWarped Wafer PreventionAnti-Static MeasuresReduced Defect Rate

.jpg)

Proposal for a transport End Effector / Handling Arm that can suck warped wafers

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Warped Wafer PreventionMisalignment PreventionImproved Functionality

Proposal for a transport End Effector / Handling Arm that can suck warped wafers

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Warped Wafer PreventionMisalignment PreventionImproved FunctionalityYield Improvement

Proposal of a End Effector / Handling Arm with PAD that can adsorb and transport warped wafers

Product Type: Wafer Transfer End Effector / Handling ArmPAD

Proposed Effect: Warped Wafer PreventionImproved Productivity(Improved Throughput)

Proposal of End Effector / Handling Arm for warping and thin wafer transfer

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Wafer Scratch PreventionWarped Wafer PreventionSuction Mark ReductionYield ImprovementParticle Control

Improved Productivity

Proposal for a Transfer End Effector / Handling Arm that can use one wafer for adsorption and floating

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Man-Hour ReductionCost ReductionImproved FunctionalityImproved Productivity

Cost reduction by remodeling the wafer Transfer End Effector / Handling Arm -holding section to a PAD

Product Type: Wafer Transfer End Effector / Handling ArmPAD

Proposed Effect: Man-Hour ReductionCost ReductionImproved FunctionalityImproved ProductivityWear Resistance

Alumina-protective cover reduces the frequency of replacement of heater components for CVD equipment

Product Type: Alumina Cover

Proposed Effect: Man-Hour ReductionCost ReductionImproved Productivity

Misalignment Prevention

.jpg)

Proposal for a transport End Effector / Handling Arm that can suck warped wafers

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Warped Wafer PreventionMisalignment PreventionImproved Functionality

Proposal for a transport End Effector / Handling Arm that can suck warped wafers

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Warped Wafer PreventionMisalignment PreventionImproved FunctionalityYield Improvement

Proposing PAD surface-treatment to prevent problems with wafer sticking

Product Type: Wafer Transfer End Effector / Handling ArmPAD

Proposed Effect: Wafer Scratch PreventionMisalignment PreventionContact Damage ReductionYield Improvement

Reduced Defect Rate

Proposing PAD to prevent static electricity

Product Type: Wafer Transfer End Effector / Handling ArmPAD

Proposed Effect: Wafer Scratch PreventionWarped Wafer PreventionAnti-Static MeasuresReduced Defect Rate

Proposal of a porous setter with low impact on the work piece and good air permeability

Product Type: Baking Setter

Proposed Effect: Contact Damage ReductionImproved FunctionalityReduced Defect RateYield Improvement

Proposal for ceramicization of masks

Product Type: Other

Proposed Effect: Deformation ReductionCost ReductionReduced Defect Rate

Reduction of defect rate of electrostatic diffusion End Effector / Handling Arm by changing coating

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Contamination MeasuresAnti-Static MeasuresSparking PreventionReduced Defect Rate

Improved Productivity(Improved Throughput)

Proposal of specially treated products that can prevent metal contamination

Product Type: Other

Proposed Effect: Improved Chemical ResistanceImproved Productivity(Improved Throughput)Man-Hour ReductionLong Service LifeMetal Contamination ControlParticle Control

Proposal for assembly of the sensor to the wafer Transfer End Effector / Handling Arm

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Improved Productivity(Improved Throughput)Improved Functionality

Proposing solutions for resin products that are worn and troublesome by using ceramics

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Wear Resistance ImprovementImproved Productivity(Improved Throughput)Man-Hour ReductionCost Reduction

Proposal of a End Effector / Handling Arm with PAD that can adsorb and transport warped wafers

Product Type: Wafer Transfer End Effector / Handling ArmPAD

Proposed Effect: Warped Wafer PreventionImproved Productivity(Improved Throughput)

Proposal of double-sided suction Porous Chuck

Product Type: Porous Chuck

Proposed Effect: Improved Productivity(Improved Throughput)Man-Hour ReductionCost ReductionImproved Functionality

大型偏光フィルムの吸着が可能な500角の大型多孔質チャックのご提案

Product Type: Porous Chuck

Proposed Effect: Deformation ReductionImproved Productivity(Improved Throughput)Suction Mark Reductionワークの傷防止

Contact Damage Reduction

Reduction of contact damage by changing the material of the wafer Transfer End Effector / Handling Arm from metal to conductive ceramics

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Contact Damage ReductionWear PreventionContamination Measures

Proposal of a porous setter with low impact on the work piece and good air permeability

Product Type: Baking Setter

Proposed Effect: Contact Damage ReductionImproved FunctionalityReduced Defect RateYield Improvement

Proposing PAD surface-treatment to prevent problems with wafer sticking

Product Type: Wafer Transfer End Effector / Handling ArmPAD

Proposed Effect: Wafer Scratch PreventionMisalignment PreventionContact Damage ReductionYield Improvement

Yield Improvement

Proposal for a transport End Effector / Handling Arm that can suck warped wafers

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Warped Wafer PreventionMisalignment PreventionImproved FunctionalityYield Improvement

Proposal of a porous setter with low impact on the work piece and good air permeability

Product Type: Baking Setter

Proposed Effect: Contact Damage ReductionImproved FunctionalityReduced Defect RateYield Improvement

Proposal of End Effector / Handling Arm for warping and thin wafer transfer

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Wafer Scratch PreventionWarped Wafer PreventionSuction Mark ReductionYield ImprovementParticle Control

Proposing PAD surface-treatment to prevent problems with wafer sticking

Product Type: Wafer Transfer End Effector / Handling ArmPAD

Proposed Effect: Wafer Scratch PreventionMisalignment PreventionContact Damage ReductionYield Improvement

Man-Hour Reduction

Proposal of specially treated products that can prevent metal contamination

Product Type: Other

Proposed Effect: Improved Chemical ResistanceImproved Productivity(Improved Throughput)Man-Hour ReductionLong Service LifeMetal Contamination ControlParticle Control

Proposal for a Transfer End Effector / Handling Arm that can use one wafer for adsorption and floating

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Man-Hour ReductionCost ReductionImproved FunctionalityImproved Productivity

Cost reduction by remodeling the wafer Transfer End Effector / Handling Arm -holding section to a PAD

Product Type: Wafer Transfer End Effector / Handling ArmPAD

Proposed Effect: Man-Hour ReductionCost ReductionImproved FunctionalityImproved ProductivityWear Resistance

Alumina-protective cover reduces the frequency of replacement of heater components for CVD equipment

Product Type: Alumina Cover

Proposed Effect: Man-Hour ReductionCost ReductionImproved Productivity

Proposing solutions for resin products that are worn and troublesome by using ceramics

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Wear Resistance ImprovementImproved Productivity(Improved Throughput)Man-Hour ReductionCost Reduction

Suggestions for integration of suction End Effector / Handling Arm cavities

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Improved Heat ResistanceMan-Hour ReductionLong Service LifeCost ReductionOutgassing Reduction

Proposal of double-sided suction Porous Chuck

Product Type: Porous Chuck

Proposed Effect: Improved Productivity(Improved Throughput)Man-Hour ReductionCost ReductionImproved Functionality

Surface Resistance Control

Proposal of a wafer Transfer End Effector / Handling Arm with superior electrostatic diffusion effect even at high temperatures

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Improved FunctionalityAnti-Static MeasuresSurface Resistance Control

Measures against static electricity and outgas in wafer Transfer End Effector / Handling Arm

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Improved Heat ResistanceAnti-Static MeasuresSurface Resistance ControlOutgassing Reduction

Particle Control

Proposal of specially treated products that can prevent metal contamination

Product Type: Other

Proposed Effect: Improved Chemical ResistanceImproved Productivity(Improved Throughput)Man-Hour ReductionLong Service LifeMetal Contamination ControlParticle Control

Proposal of End Effector / Handling Arm for warping and thin wafer transfer

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Wafer Scratch PreventionWarped Wafer PreventionSuction Mark ReductionYield ImprovementParticle Control

Suction Mark Reduction

Proposal of End Effector / Handling Arm for warping and thin wafer transfer

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Wafer Scratch PreventionWarped Wafer PreventionSuction Mark ReductionYield ImprovementParticle Control

パワー半導体向け薄反りウエハの保持・吸着が可能な多孔質埋め込みハンドのご提案

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Wafer Scratch PreventionSuction Mark Reduction

大型偏光フィルムの吸着が可能な500角の大型多孔質チャックのご提案

Product Type: Porous Chuck

Proposed Effect: Deformation ReductionImproved Productivity(Improved Throughput)Suction Mark Reductionワークの傷防止

Outgassing Reduction

Measures against static electricity and outgas in wafer Transfer End Effector / Handling Arm

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Improved Heat ResistanceAnti-Static MeasuresSurface Resistance ControlOutgassing Reduction

Suggestions for integration of suction End Effector / Handling Arm cavities

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Improved Heat ResistanceMan-Hour ReductionLong Service LifeCost ReductionOutgassing Reduction

Deformation Reduction

Proposal for ceramicization of masks

Product Type: Other

Proposed Effect: Deformation ReductionCost ReductionReduced Defect Rate

大型偏光フィルムの吸着が可能な500角の大型多孔質チャックのご提案

Product Type: Porous Chuck

Proposed Effect: Deformation ReductionImproved Productivity(Improved Throughput)Suction Mark Reductionワークの傷防止

Improved Plasma Resistance

Long Service Life

Proposal of specially treated products that can prevent metal contamination

Product Type: Other

Proposed Effect: Improved Chemical ResistanceImproved Productivity(Improved Throughput)Man-Hour ReductionLong Service LifeMetal Contamination ControlParticle Control

Suggestions for integration of suction End Effector / Handling Arm cavities

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Improved Heat ResistanceMan-Hour ReductionLong Service LifeCost ReductionOutgassing Reduction

Contamination Measures

Reduction of contact damage by changing the material of the wafer Transfer End Effector / Handling Arm from metal to conductive ceramics

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Contact Damage ReductionWear PreventionContamination Measures

Reduction of defect rate of electrostatic diffusion End Effector / Handling Arm by changing coating

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Contamination MeasuresAnti-Static MeasuresSparking PreventionReduced Defect Rate

Cost Reduction

Proposal for a Transfer End Effector / Handling Arm that can use one wafer for adsorption and floating

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Man-Hour ReductionCost ReductionImproved FunctionalityImproved Productivity

Cost reduction by remodeling the wafer Transfer End Effector / Handling Arm -holding section to a PAD

Product Type: Wafer Transfer End Effector / Handling ArmPAD

Proposed Effect: Man-Hour ReductionCost ReductionImproved FunctionalityImproved ProductivityWear Resistance

Alumina-protective cover reduces the frequency of replacement of heater components for CVD equipment

Product Type: Alumina Cover

Proposed Effect: Man-Hour ReductionCost ReductionImproved Productivity

Proposing solutions for resin products that are worn and troublesome by using ceramics

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Wear Resistance ImprovementImproved Productivity(Improved Throughput)Man-Hour ReductionCost Reduction

Proposal for ceramicization of masks

Product Type: Other

Proposed Effect: Deformation ReductionCost ReductionReduced Defect Rate

Suggestions for integration of suction End Effector / Handling Arm cavities

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Improved Heat ResistanceMan-Hour ReductionLong Service LifeCost ReductionOutgassing Reduction

Proposal of double-sided suction Porous Chuck

Product Type: Porous Chuck

Proposed Effect: Improved Productivity(Improved Throughput)Man-Hour ReductionCost ReductionImproved Functionality

Wafer Transfer End Effector / Handling Arm

Proposing PAD to prevent static electricity

Product Type: Wafer Transfer End Effector / Handling ArmPAD

Proposed Effect: Wafer Scratch PreventionWarped Wafer PreventionAnti-Static MeasuresReduced Defect Rate

Reduction of contact damage by changing the material of the wafer Transfer End Effector / Handling Arm from metal to conductive ceramics

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Contact Damage ReductionWear PreventionContamination Measures

.jpg)

Proposal for a transport End Effector / Handling Arm that can suck warped wafers

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Warped Wafer PreventionMisalignment PreventionImproved Functionality

Proposal for a transport End Effector / Handling Arm that can suck warped wafers

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Warped Wafer PreventionMisalignment PreventionImproved FunctionalityYield Improvement

Proposal for a portable wafer Transfer End Effector / Handling Arm

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Improved FunctionalityPortability

Proposal for a Transfer End Effector / Handling Arm that can use one wafer for adsorption and floating

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Man-Hour ReductionCost ReductionImproved FunctionalityImproved Productivity

Cost reduction by remodeling the wafer Transfer End Effector / Handling Arm -holding section to a PAD

Product Type: Wafer Transfer End Effector / Handling ArmPAD

Proposed Effect: Man-Hour ReductionCost ReductionImproved FunctionalityImproved ProductivityWear Resistance

Proposal of a wafer Transfer End Effector / Handling Arm with superior electrostatic diffusion effect even at high temperatures

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Improved FunctionalityAnti-Static MeasuresSurface Resistance Control

Proposal for assembly of the sensor to the wafer Transfer End Effector / Handling Arm

Product Type: Wafer Transfer End Effector / Handling Arm

Proposed Effect: Improved Productivity(Improved Throughput)Improved Functionality

Porous Chuck

Proposal of double-sided suction Porous Chuck

Product Type: Porous Chuck

Proposed Effect: Improved Productivity(Improved Throughput)Man-Hour ReductionCost ReductionImproved Functionality

大型偏光フィルムの吸着が可能な500角の大型多孔質チャックのご提案

Product Type: Porous Chuck

Proposed Effect: Deformation ReductionImproved Productivity(Improved Throughput)Suction Mark Reductionワークの傷防止

PAD

Proposing PAD to prevent static electricity

Product Type: Wafer Transfer End Effector / Handling ArmPAD

Proposed Effect: Wafer Scratch PreventionWarped Wafer PreventionAnti-Static MeasuresReduced Defect Rate

Cost reduction by remodeling the wafer Transfer End Effector / Handling Arm -holding section to a PAD

Product Type: Wafer Transfer End Effector / Handling ArmPAD

Proposed Effect: Man-Hour ReductionCost ReductionImproved FunctionalityImproved ProductivityWear Resistance

Proposal of a End Effector / Handling Arm with PAD that can adsorb and transport warped wafers

Product Type: Wafer Transfer End Effector / Handling ArmPAD

Proposed Effect: Warped Wafer PreventionImproved Productivity(Improved Throughput)

Proposing PAD surface-treatment to prevent problems with wafer sticking

Product Type: Wafer Transfer End Effector / Handling ArmPAD

Proposed Effect: Wafer Scratch PreventionMisalignment PreventionContact Damage ReductionYield Improvement

Other

Proposal of specially treated products that can prevent metal contamination

Product Type: Other

Proposed Effect: Improved Chemical ResistanceImproved Productivity(Improved Throughput)Man-Hour ReductionLong Service LifeMetal Contamination ControlParticle Control

Proposal for ceramicization of masks

Product Type: Other

Proposed Effect: Deformation ReductionCost ReductionReduced Defect Rate

Material change to Black Alumina pin

Product Type: Other

Proposed Effect: Wear Resistance ImprovementImproved Heat ResistanceImproved Plasma Resistance

We will solve your problems using our unique proprietary technology.

See examples of ceramic parts we haveprovided to device manufacturers and other customers invarious industries.

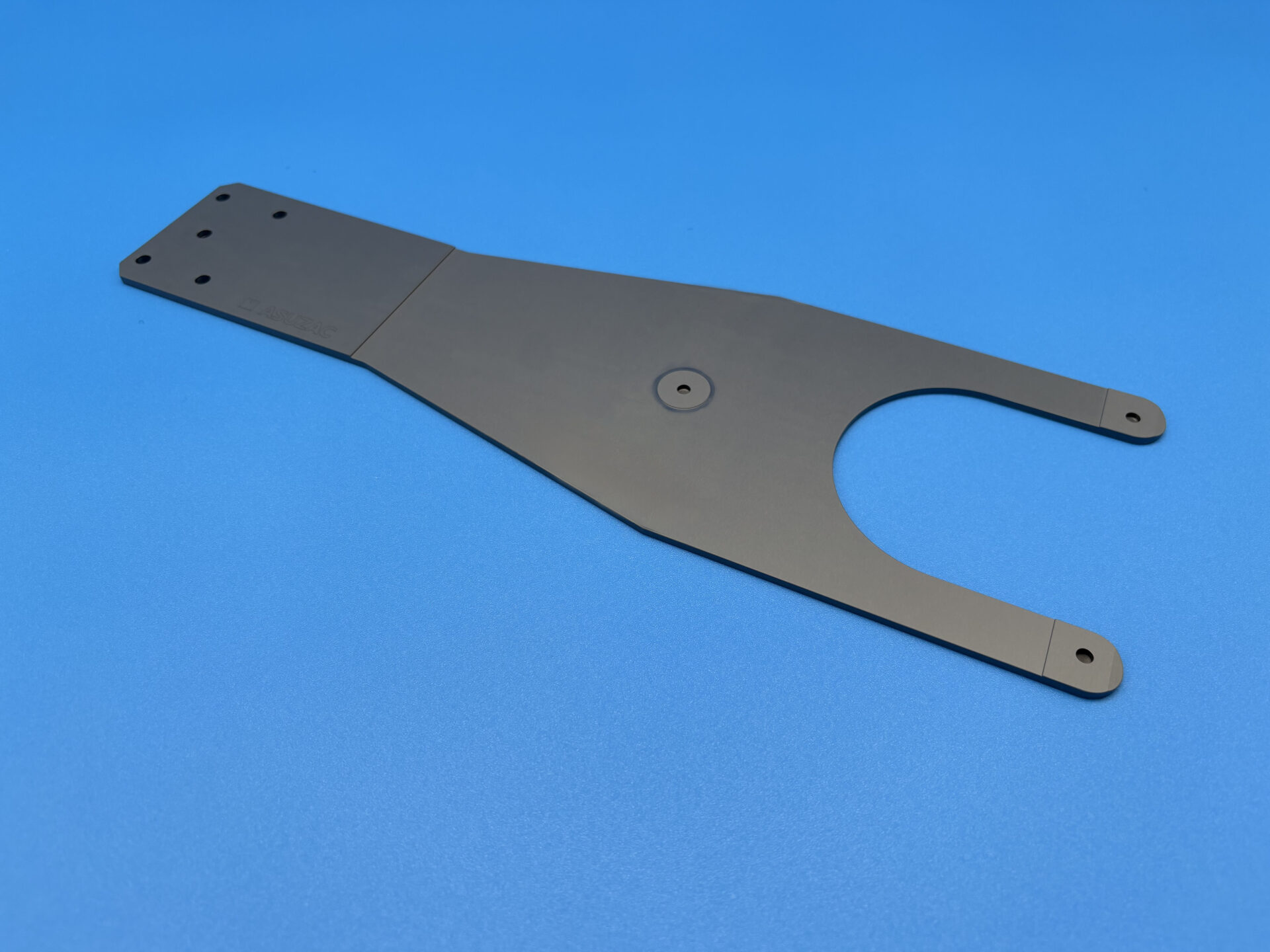

高耐熱性12インチウエハ吸着用 SiC搬送ハンド(UniZac-air®)

6インチウエハ吸着用 ロボット搬送ハンド(UniZac-air®)

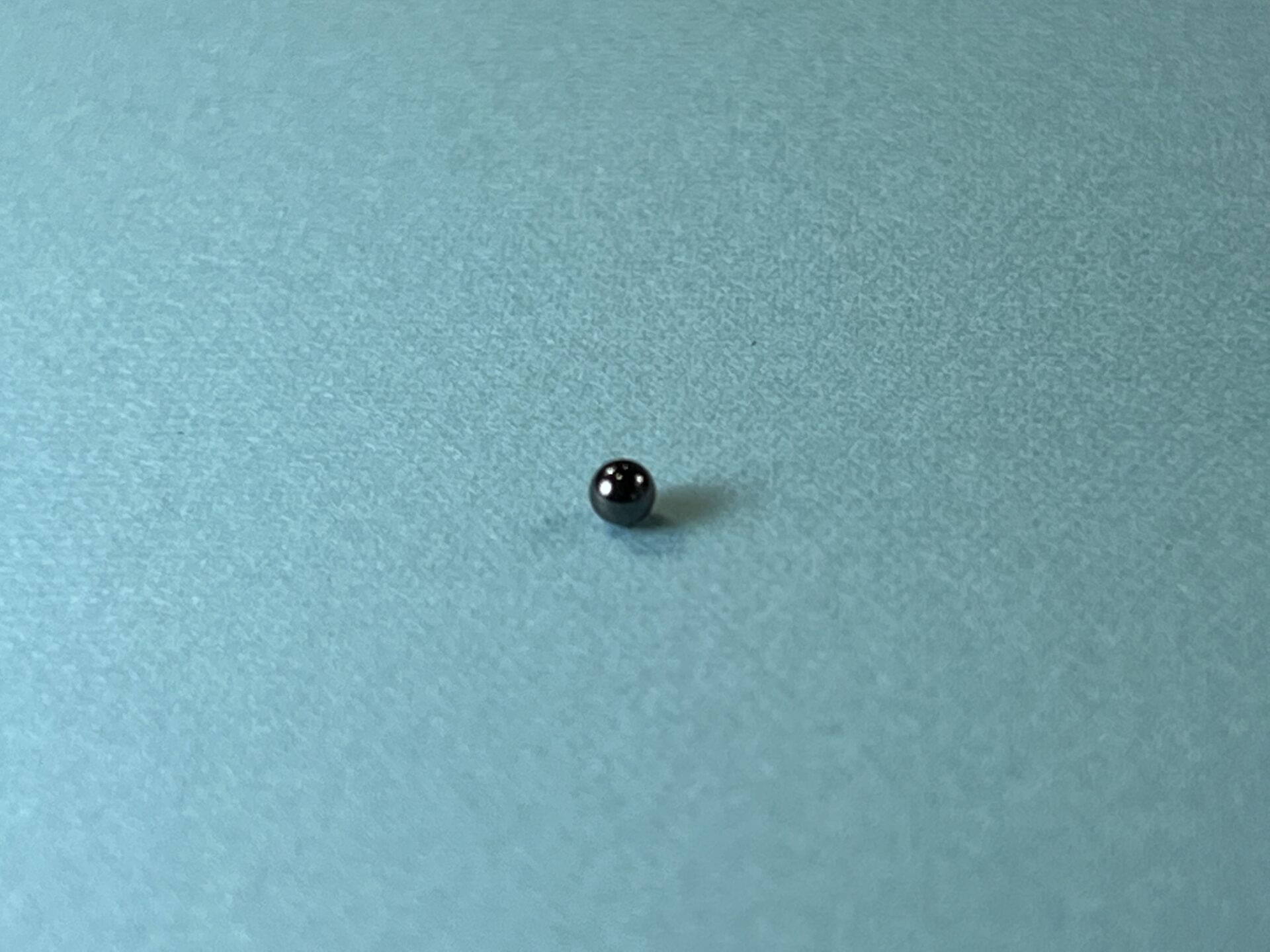

精密セラミックボール(炭化ケイ素SiC3N)

.jpg)

高耐熱性4~8インチウエハ吸着用 SiC搬送ハンド(UniZac-air®)

.jpg)

UniZac-air® (ユニザックエア) センサー溝付き空洞一体ハンド(12インチ用)

ケガキ線付き4~8インチウエハ吸着用I型ベルヌーイハンド(LeviZac®薄型)

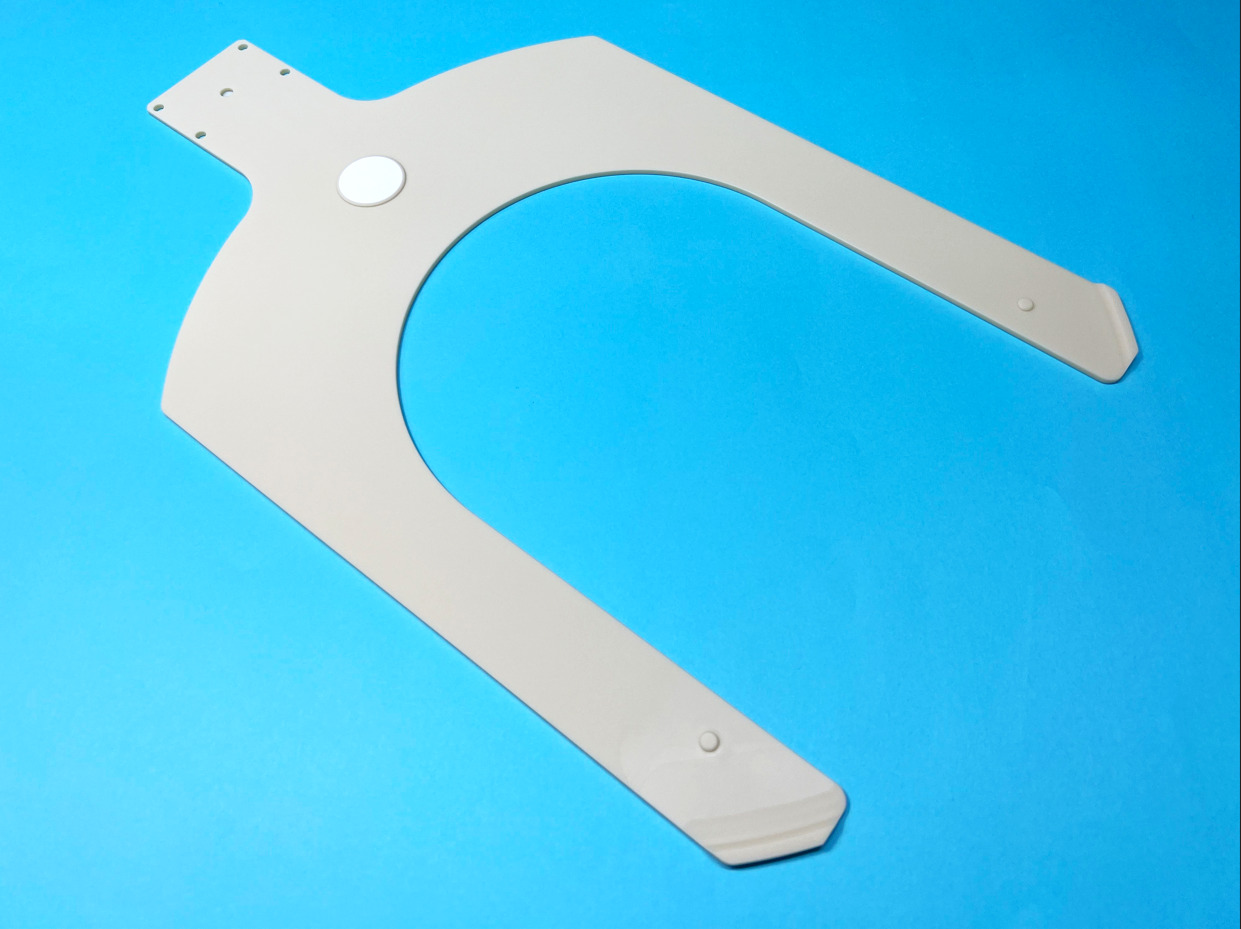

反りウエハ対応搬送ハンド1点吸着仕様多孔質埋め込みハンド12インチ(UniZac-Pair)

12インチウエハ搬送用 トレイ式軽量化ハンド(UniZac-Obon®)

.jpg)

Φ200×t 0.5 SiCダミーウエハ(反り量0.5 mm)【常圧焼結品/多結晶体】

500角吸着用 大型多孔質チャック(多孔質AZP60、本体アルミ)

試作品のオリジナルハンドUniZac-Obon®について、内部に空洞部を複数設けることで、約10 %の軽量化に成功しまし...

.jpg)

ウエハ保持部に段差を設けたことで、反りウエハを吸着させやすくした搬送ハンドです。詳細は以下をご覧ください。 ...

反ったウエハを搬送する際、カセットに接触し、ウエハが破損したことはありませんか。当社の UniZac-air®(1.2 ...

Frequently Asked Questions

Common questions from

the Ceramics Design Lab

Available Material / Size / Product

Please see our wide range of

services

Equipment owned

Our processing and

inspection facilities

Company profile

Ceramics Design Lab is

operated by Asuzac Co., Ltd.

The quotation and inquiries are available by the telephone /FAX or the mail .

FAX. +81-26-251-2160