-

ProblemsDeformation

Defect Rate -

Proposed EffectDeformation Reduction

Cost Reduction

Reduced Defect Rate -

Product TypeOther

Customer's concerns and problems / Before

Our proposals and improvement effects / After

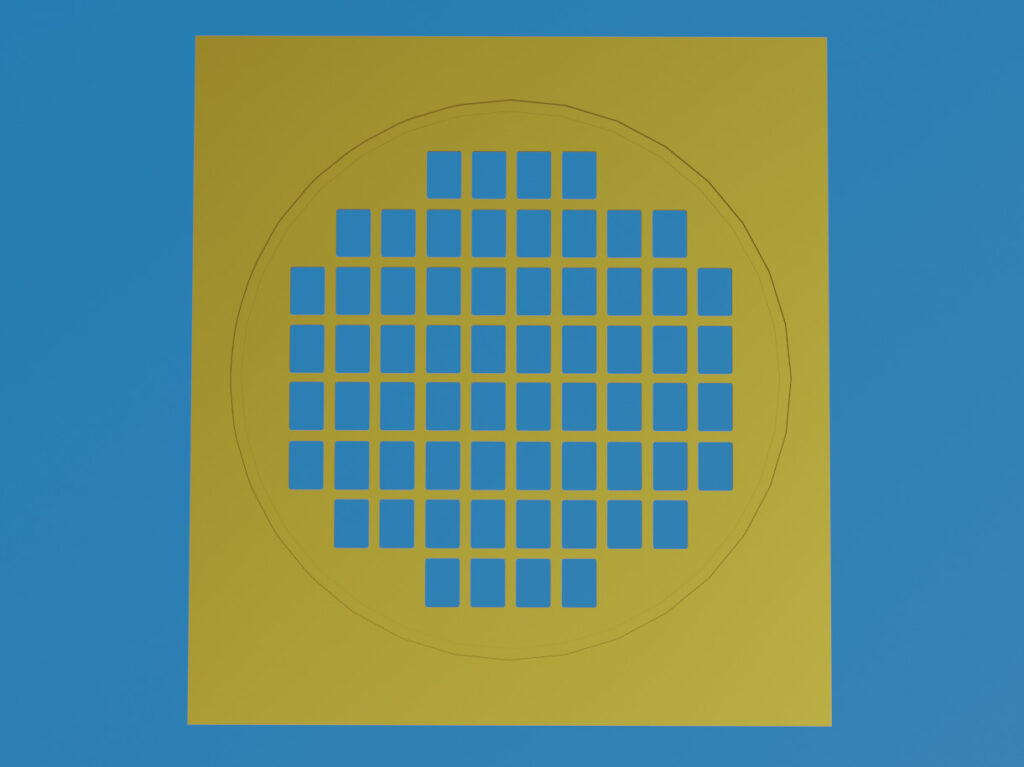

Asuzac suggested that the mask be made of metal and ceramics.

In order to increase the number of wafers taken, the mask shape was designed and manufactured from the conventional product.

Ceramics masks are less distorted than metal masks, resulting in a lower defect rate and lower costs.

Point of the proposed example / Point

The point of this case is that the service life has been extended more than twice as long by using ceramics from metal materials.

By taking advantage of the light weight, high rigidity, and high strength that are characteristics of ceramics, it is possible to achieve excellent effects.

The Fine Ceramics Division of ASUZAC Corporation, which operates the Ceramics Design Laboratory, handles everything from material development and preparation to design and manufacture, as well as surface treatment, inspection, and cleaning.

We can also offer our own coating-technology for adding functionality to ceramics materials, as well as the selection of materials such as ceramic materials with high heat resistance and conductivity, and high-purity alumina and SiC that are highly pure and prevent contamination.

Please feel free to contact us if you have any problems with mask components for existing deposition processes.

Integrated response from processing to development of ceramic materials !

Please feel free to contact us !

Business hours: 9:00-17:00 (closed on Saturdays, Sundays and Holidays)

.jpg)

.jpg)

In the past, metal masks were used in the film-forming process, and they said that distortion occurred in the masks, leading to an increase in defects.