For fine ceramic products such as Transfer End Effector / Handling Arm and Porous Chuck

made in Japan

<Telephone quotations/inquiries>

TEL+81-26-248-1626

Business hours: 9:00-17:00

(closed on Saturdays, Sundays and Holidays)

We introduce custom-made ceramics parts that we have provided to customers in various industries, including device manufacturers.

- Latest Cases

- Search by

Industry - Search by

Product Type - Search by

Material

-

2022.11.30

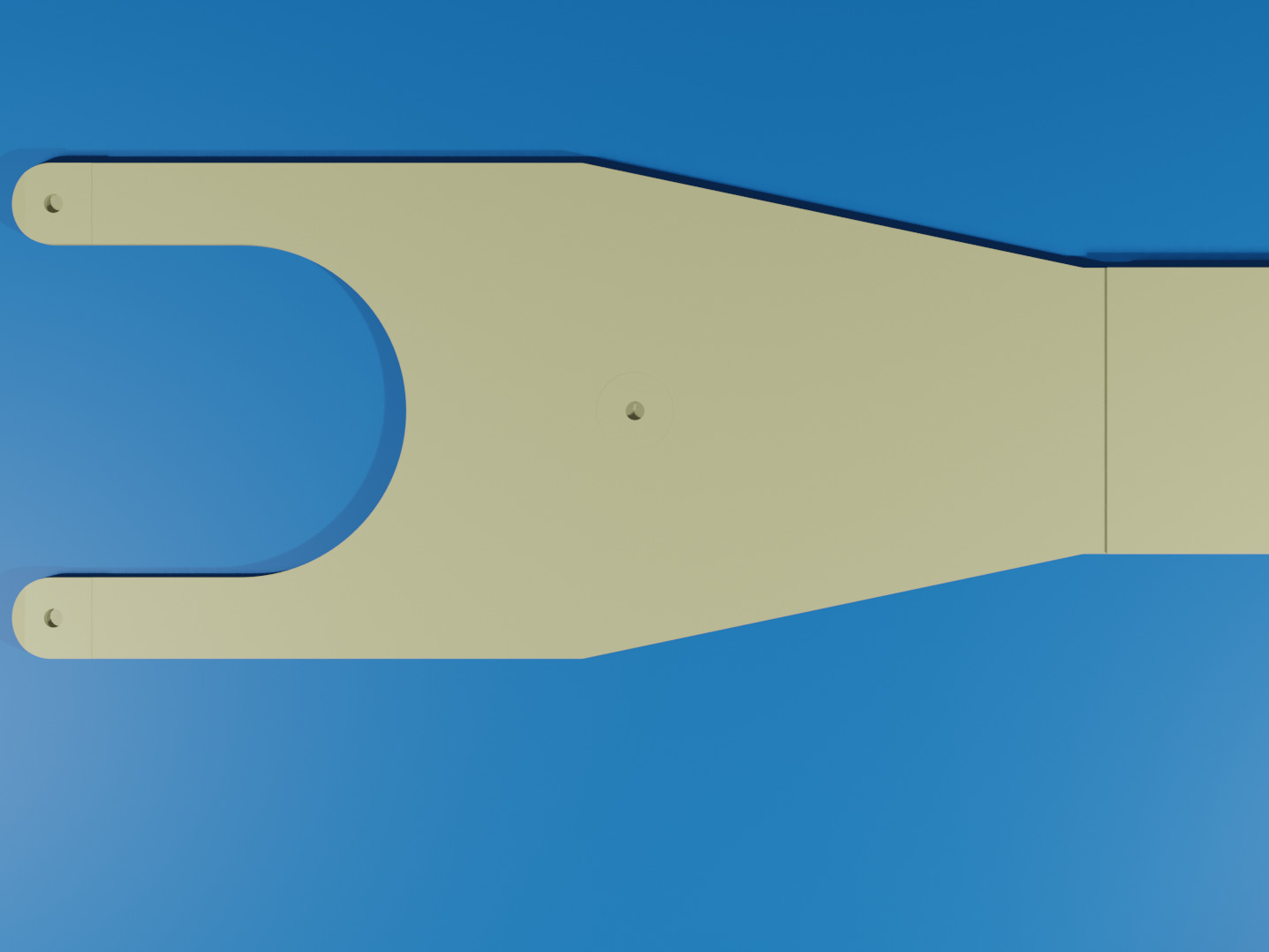

2022.11.30Robot Transfer End Effector / Handling Arm for 12-inch Wafer Suction (UniZac-air®)

Industry: Semiconductor

Material: High Purity Alumina

-

2022.11.30

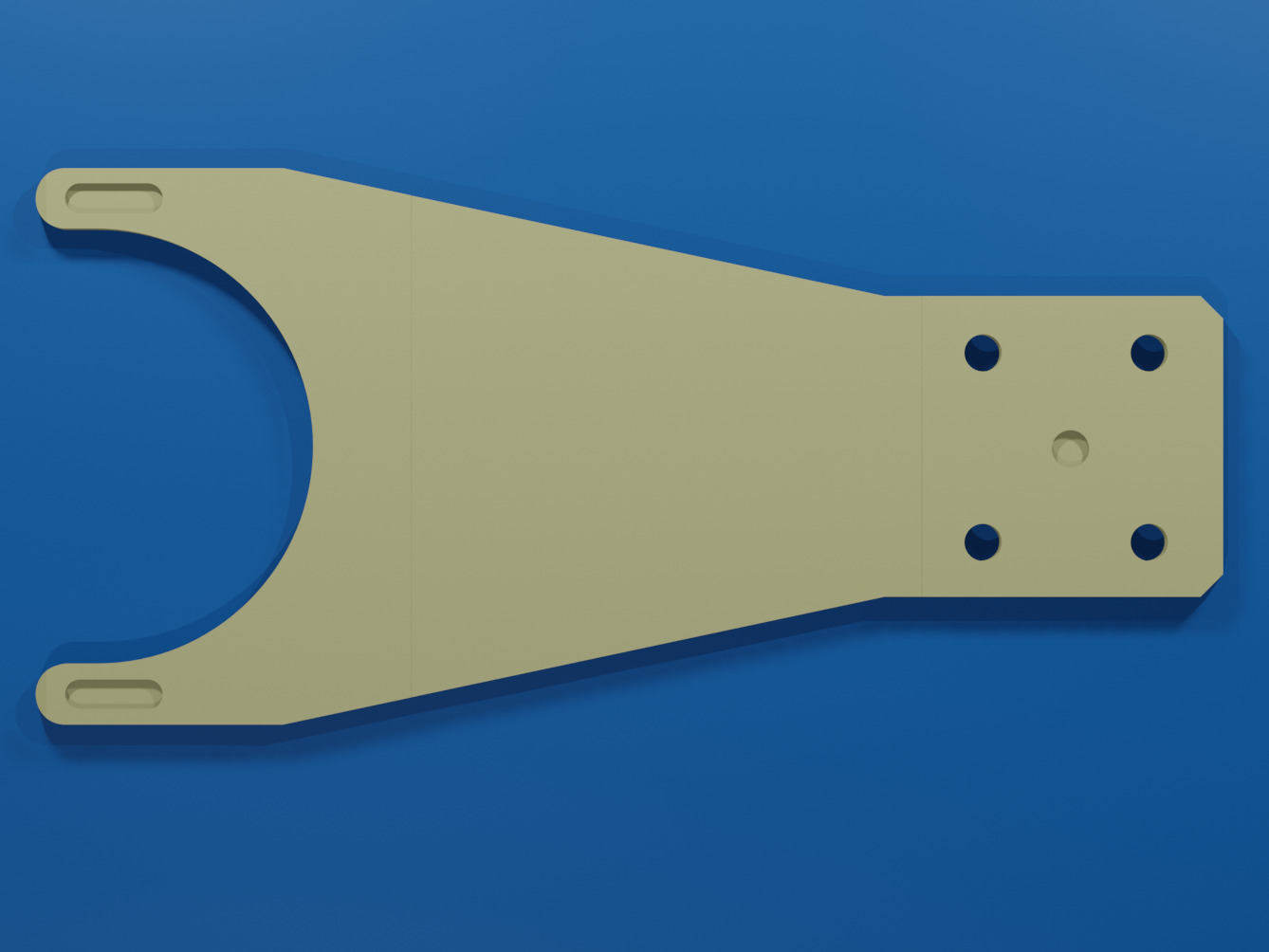

2022.11.30Robot Transfer End Effector / Handling Arm for 8-inch Wafer Suction (UniZac-air®)

Industry: Semiconductor

Material: High Purity Alumina

-

2022.11.30

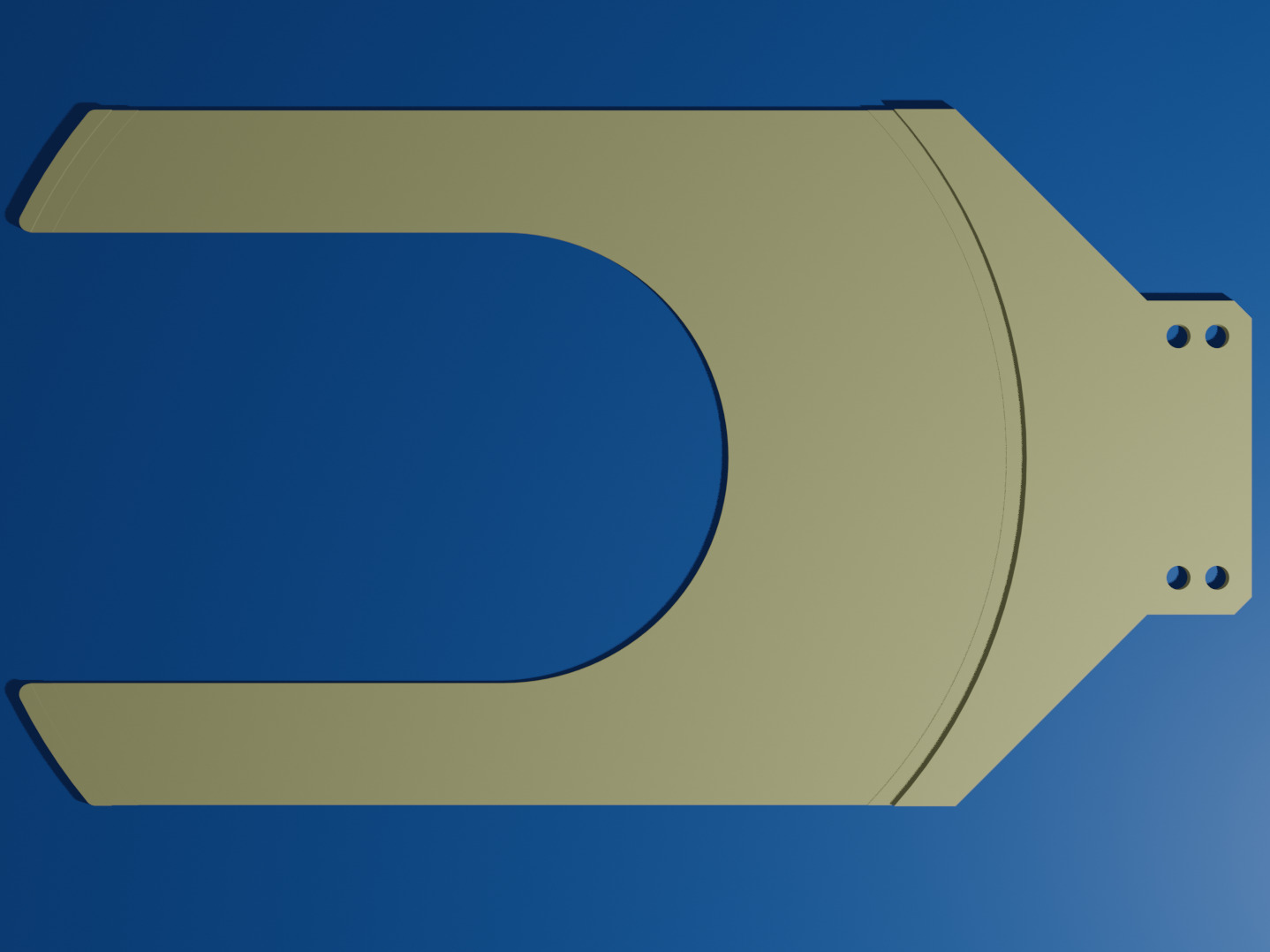

2022.11.30Tray-type End Effector / Handling Arm for 12-inch wafer transfer (UniZac-Obon®)

Industry: Semiconductor

Material: High Purity Alumina

-

2022.11.30

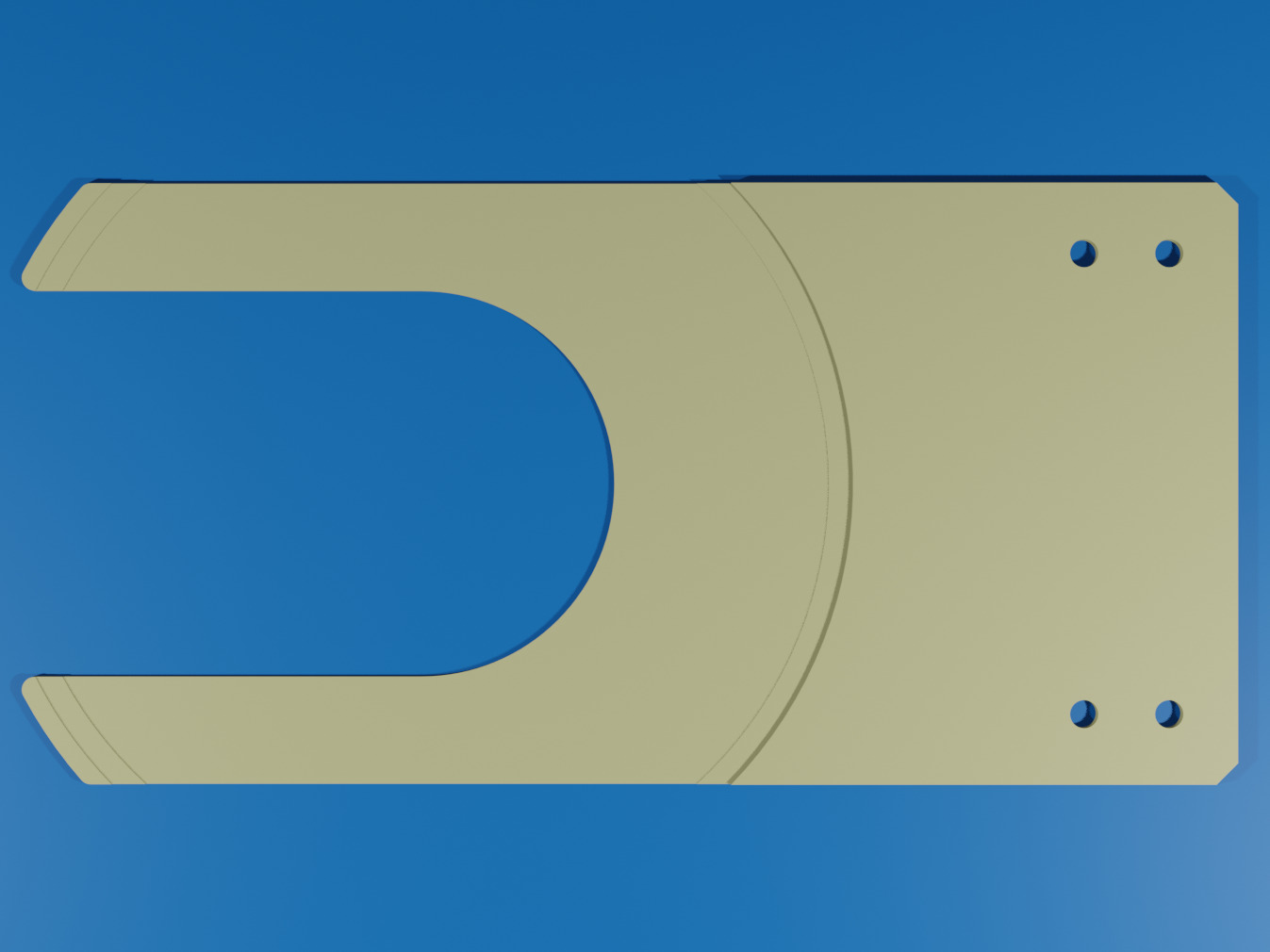

2022.11.30Tray-type End Effector / Handling Arm for 8-inch wafer transfer (UniZac-Obon®)

Industry: Semiconductor

Material: High Purity Alumina

-

2022.11.30

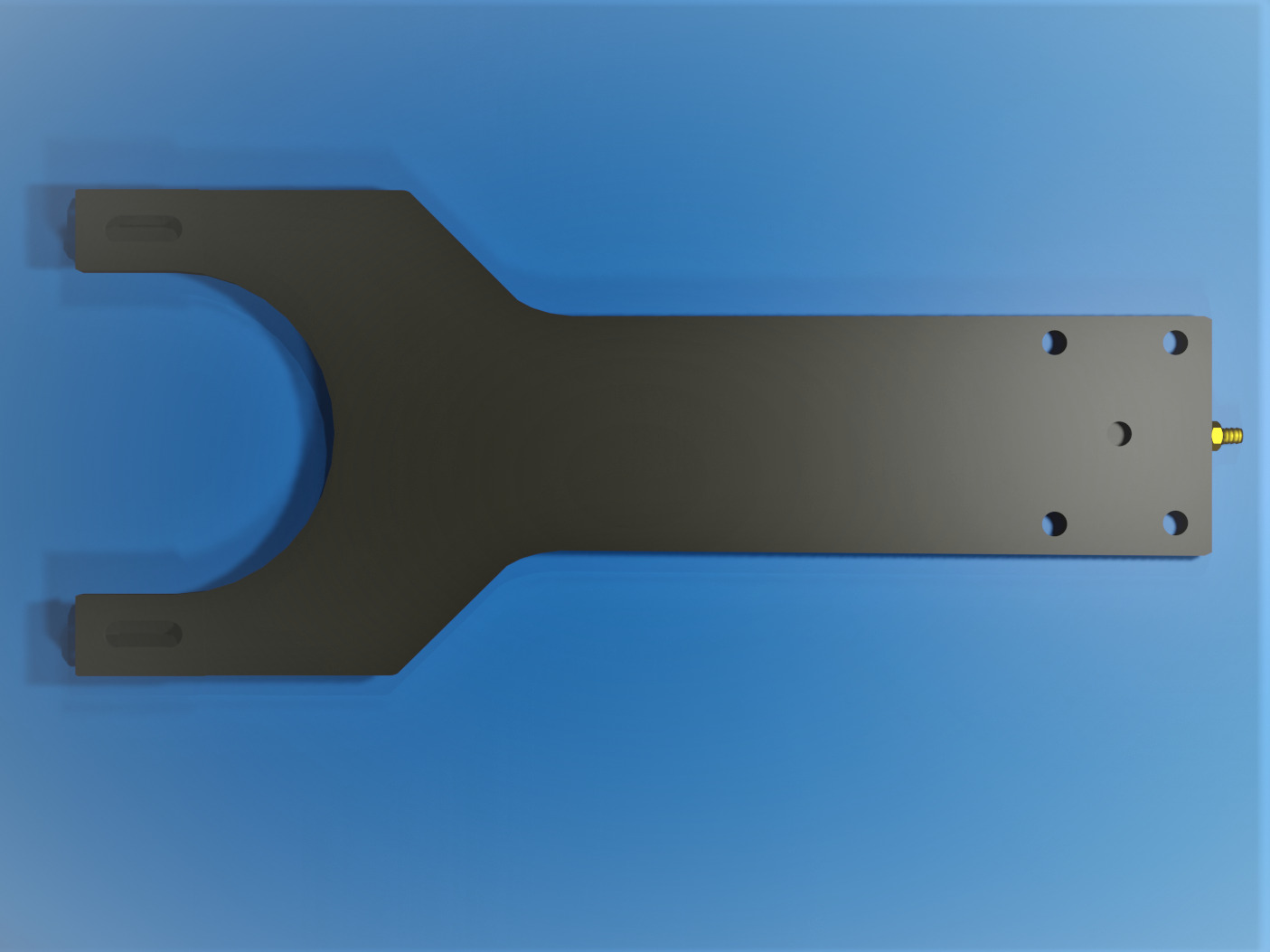

2022.11.30Electrostatic Diffusion Black Alumina wafer Transfer End Effector / Handling Arm

Industry: Semiconductor

Material: Static Electricity Diffusion Alumina,High Purity Alumina

-

2022.11.30

2022.11.30Robot Transfer End Effector / Handling Arm for 4-inch Wafer Suction

Industry: Semiconductor

Material: High Purity Alumina

-

2022.11.30

2022.11.30SiC firing setters

Industry: Ceramics firing jig

Material: SiC(Silicon Carbide)

-

2022.11.30

2022.11.30High Purity SiC plated (SiC3N)

Industry: Other

Material: High Purity Silicon Carbide

-

2022.11.30

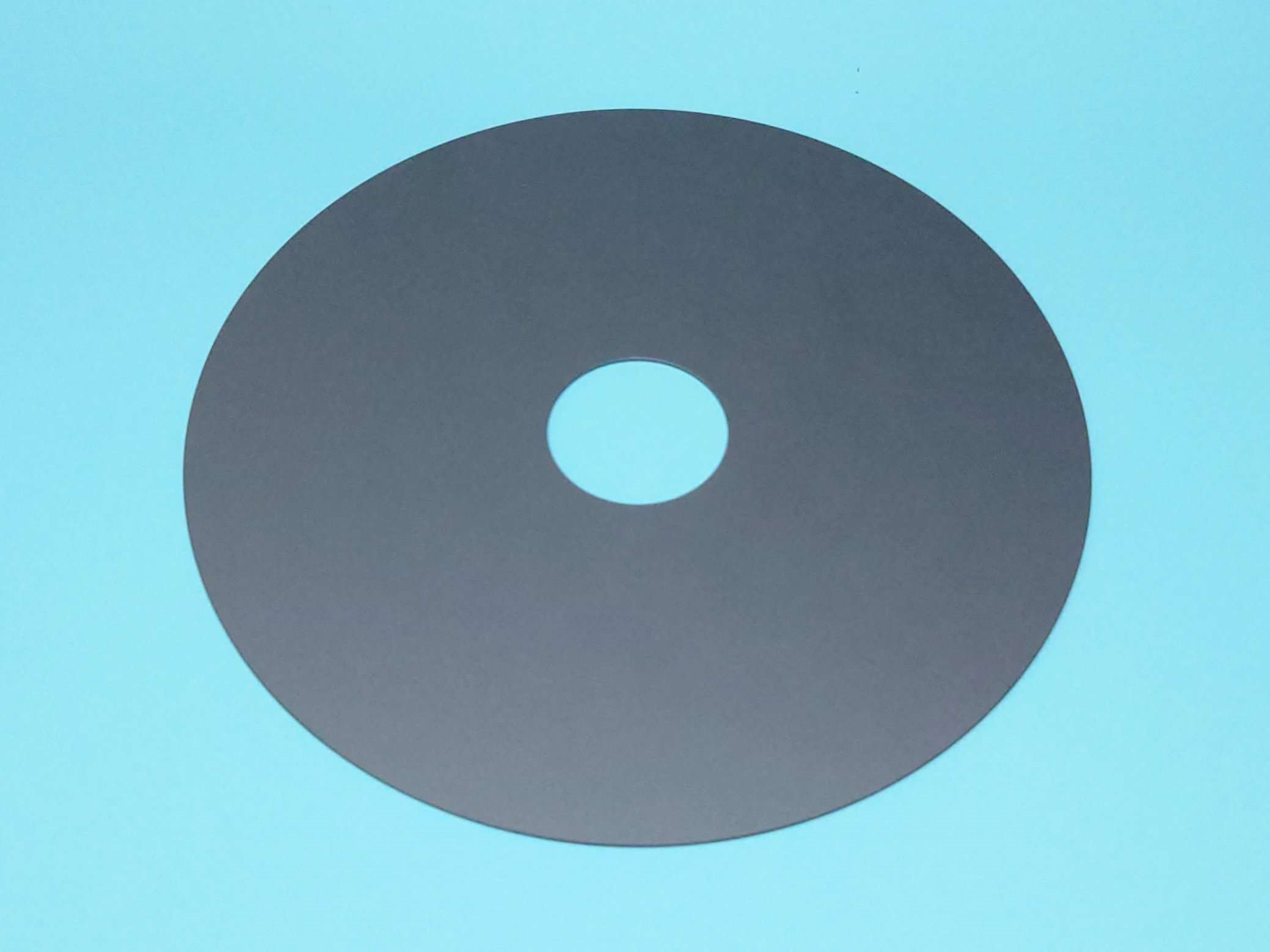

2022.11.30Porous Alumina Chuck for 6-inch wafer adsorption (Body A5052)

Industry: Semiconductor,Industrial machinery,Film

Material: Porous Ceramics

-

2022.11.30

2022.11.30Porous SiC chuck (Body Alumina)

Industry: Industrial machinery,Film,University・Research institute

Material: High Purity Alumina,Porous Ceramics

-

2022.11.30

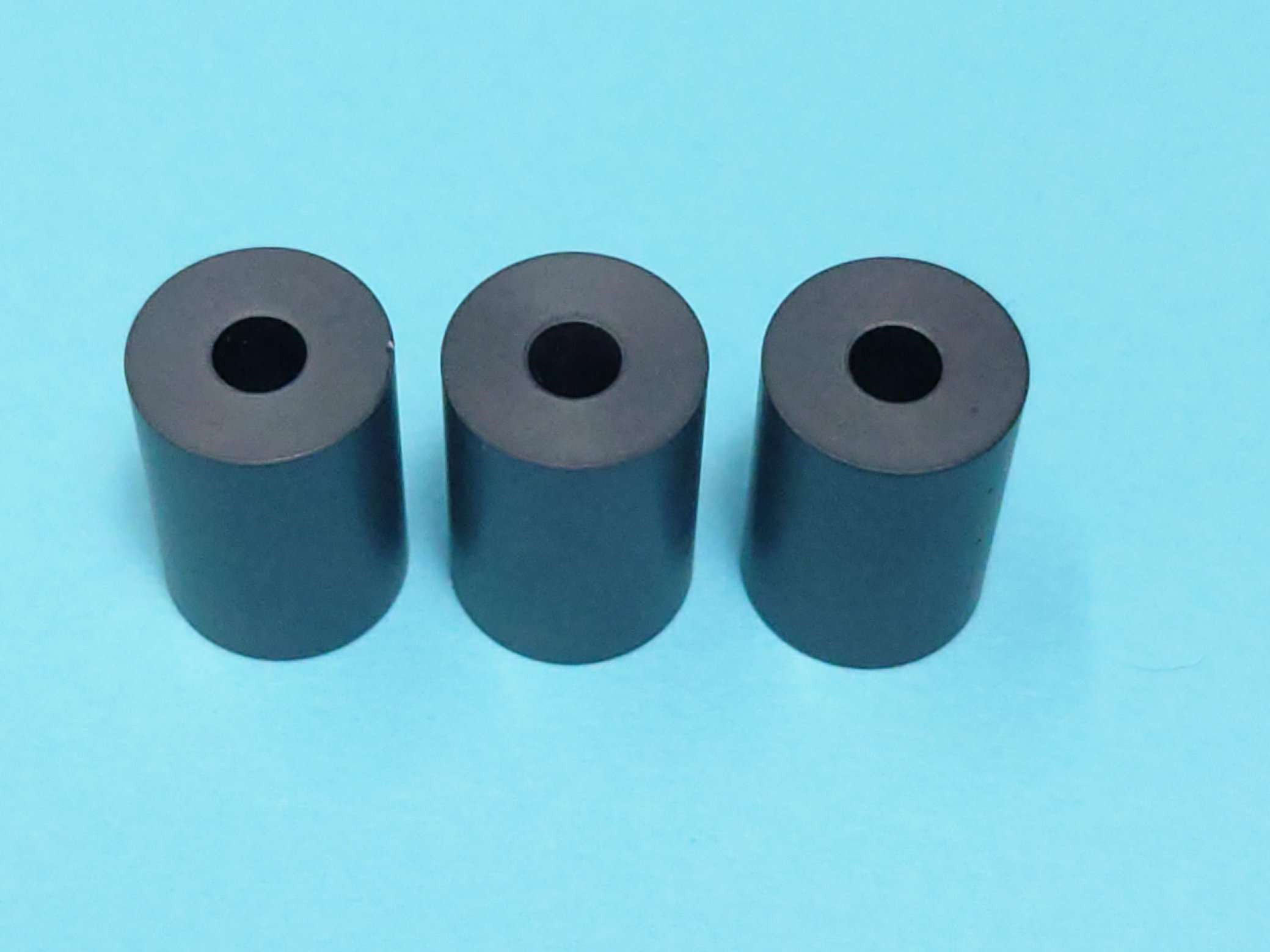

2022.11.30Cylindrical SiC part

Industry: Industrial machinery,Film,University・Research institute

Material: SiC(Silicon Carbide)

-

2022.11.30

2022.11.30Thrust pin made of conductive ceramics (Thrust needle)

Industry: Semiconductor

Material: Conductive Ceramics

-

Look for from the industry

-

Search from the product type

-

Look for materials

-

Examples of VA / VE

proposals for design developers -

PRODUCTS AND SERVICES

-

Latest technology column

-

CONTENT

-

Frequently Asked Questions

Common questions from

the Ceramics Design Lab -

Available Material / Size / Product

Please see our wide range of

services -

Equipment owned

Our processing and

inspection facilities -

Company profile

Ceramics Design Lab is

operated by Asuzac Co., Ltd.

CONTACT

The quotation and inquiries are available by the telephone /FAX or the mail .

FAX. +81-26-251-2160

v4.jpeg)

(本体アルミ、多孔質AZP60)v1.jpg)

外形120×80×厚み10mm-v1.jpg)

v1.jpg)

.jpg)