| Product Name | Porous embedded End Effector / Handling Arm |

|---|---|

| Classification | Adsorption End Effector / Handling Arm |

| Use | For wafer transport (atmospheric use) |

| Material | Adsorption part:Porous ceramics,Body:Alumina and SiC(Silicon Carbide) |

| Feature |

Transfer of thin warped wafers is possible. Hard to adsorb traces on wafers. |

| Size |

12": 350 × 220 mm (outer dimension), 3.5 mm (thickness) 8": 280 × 140 mm (outer dimension), 3.5 mm (thickness) |

Features Of This Product

Features of "Porous embedded End Effector / Handling Arm"

-

Transfer of thin warped wafers is possible.

Hard to adsorb traces on wafers.

Narrow cassette pitch can be supported.

Shape of "Porous embedded End Effector / Handling Arm"

-

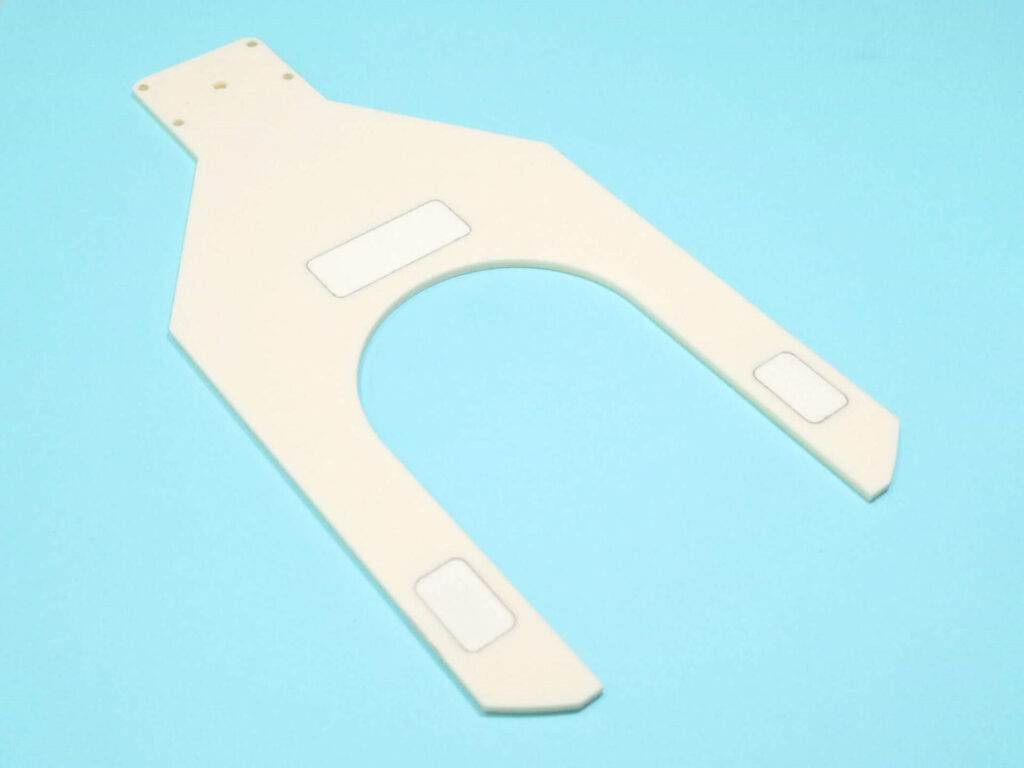

Figure 1 shows the appearance of a 12-inch porous embedded End Effector / Handling Arm with three porous locations to pick up and hold wafers.

-

Figure 2 shows the appearance of an 8-inch porous embedding End Effector / Handling Arm with three porous locations to pick up and hold wafers.

-

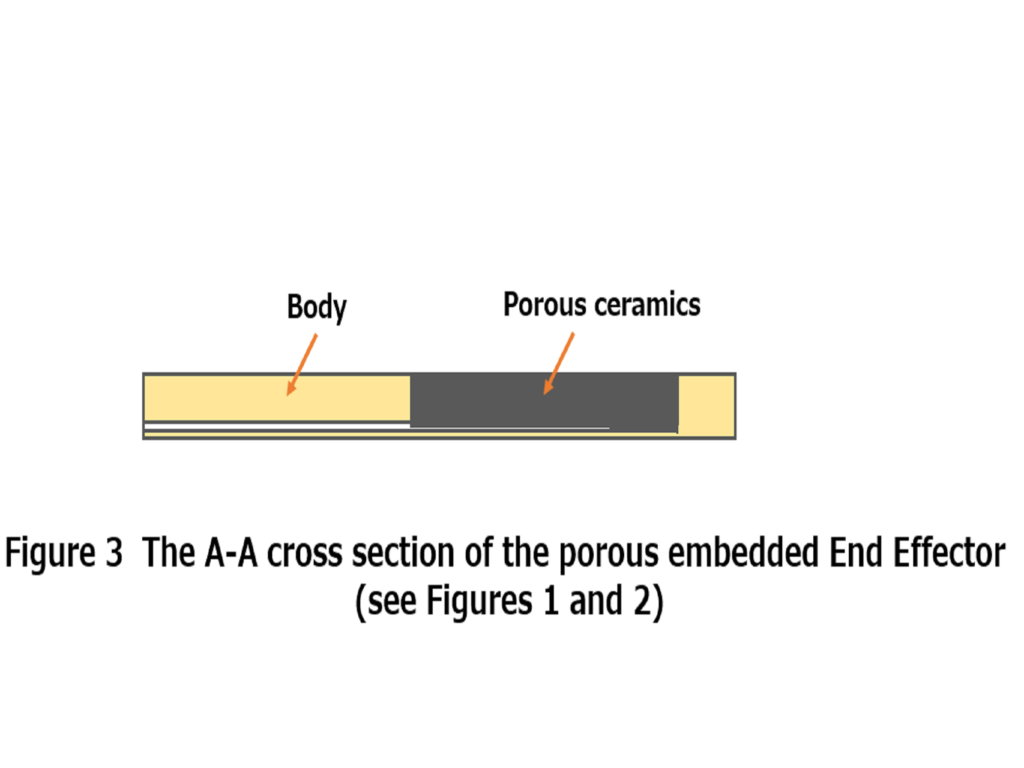

Figure 3 shows the A-A cross section of the porous hand (see Figures 1 and 2). Porous ceramics are bonded to the main body with adhesive.

Examples and achievements of "Porous embedded End Effector / Handling Arm"

Frequently Asked Questions on "Porous embedded End Effector / Handling Arm"

-

The porous embedded End Effector / Handling Arm holds the wafer with a porous suction.Therefore, deformation of the wafer during suction can be minimized.

-

We propose a porous embedded End Effector / Handling Arm.Porous is less prone to adsorption marks on the tape compared to suction holes or resin pads due to its microporous nature.

-

Yes, we use an adhesive. Adhesive is used to bond the body and the porous material.

-

Yes, we can manufacture porous embedding hands for 4-inch, 5-inch, and 6-inch wafers.Please contact us for details.

-

Yes, the wafer is held by the three porous parts.

-

Yes, it is possible. We will make a design proposal according to the shape of the equipment. Please contact us for details.

-1024x768.jpg)

-1024x768.jpg)

.jpg)

The wafer adsorption part is porous ceramics.

The body can be made of alumina and silicon carbide.

Porous ceramics are embedded in the main body using adhesives.

The End Effector / Handling Arm is characterized by its resistance to adsorption marks on the wafer.

Thin and warped wafers can be adsorbed.