What is ceramics?

Ceramics is a general term for materials or products (ceramics products) made by blending, molding, and firing non-metallic inorganic raw materials. Along with metal materials and polymer materials (plastics, rubber, etc.), they form one of the “three major materials”, and in terms of familiar objects, glass, ceramics, cement, etc. are types of ceramics.

The history of humans and ceramics is overwhelmingly older than metals, dating back more than 15,000 years. Earthenware made for boiling and storing food was considered to be the first, and later, with the development of firing technology, pottery and porcelain were acquired. In the 19th century, industrial ceramics such as glass, cement, and refractories were developed and mass-produced. In the 20th century, against the backdrop of technological innovations in the purification of raw materials, composition manipulation, and manufacturing processes, fine ceramics (details will be described later) with dramatically improved functionality appeared. Along with engineering plastics, which began to become popular at the same time, material manufacturers around the world began to actively engage in material development, which continues to this day.

Differences between ceramics, metals, and resins (plastics)

What is the difference between ceramics, metals, and resins (plastics), which are representative polymer materials? The excellent characteristics of ceramics when compared to metals and resins are shown below.

・High hardness

・Abrasion resistance

・Heat resistance

・Coefficient of thermal expansion (coefficient of thermal expansion is small)

・Dimensional stability

・Insulation

・Corrosion resistance

・Chemical resistance

・Chemical stability

On the other hand,

・Brittleness

・Workability

・Thermal shock fracture characteristics

Since it also has disadvantages such as, it may be necessary to handle it with care.

What is Fine ceramics?

What is fine ceramics?

Next, we will talk about fine ceramics (English: Fine Ceramics). Ceramics (ceramics in a broad sense) are classified into old ceramics (ceramics in the narrow sense) represented by ceramics and glass made from natural minerals such as clay and feldspar, and fine ceramics manufactured by making full use of advanced blending, molding, and firing technologies after controlling the chemical composition of artificially generated raw materials that have been refined to high purity and artificially produced, as mentioned above. The latter is sometimes called new ceramics in contrast to the former.

Fine ceramics can be further subdivided into two types: (1) engineering ceramics and (2) machinable ceramics (free-cutting ceramics). In (1), since the material is fired at a high temperature after forming, cutting with a lathe or machining center is basically impossible, and finishing is performed by grinding or polishing. On the other hand, (2) can be cut because it is not fired, and the degree of shape freedom is relatively high. However, compared to metal and resin materials, they have high hardness, are easy to chip, and have poor workability. In addition, the wear resistance is worse than (1).

Types of Fine ceramics and three points in processing

This section explains the types of fine ceramics and points to note in processing.

Here, fine ceramics = engineering ceramics. Typical fine ceramics with a large circulation are as follows.

・Alumina (Al₂O₃)

・Silicon carbide (SiC)

・Zirconia (ZrO₂)

・Aluminum nitride (AlN)

・Silicon nitride (Si₃N₄)

Alumina has the largest distribution volume, and like silicon carbide, it is used as abrasives, abrasives, refractory materials, semiconductor substrates and other electronic components, spark plugs (spark plugs), mold materials, etc. Zirconia is also useful in industrial applications as sliding parts and industrial cutters, and is also used in jewelry, ornaments, and dental treatment.

The above is classified according to material, but in recent years, the demand for special ceramics materials with improved or added specific functions has been increasing.

Ceramics with special functionality include:

・Porous ceramics

・Conductive ceramics

・Heat-resistant ceramics (high-heat-resistant ceramics)

There is such a thing.

About ASUZAC Fine Ceramics Division

The Fine Ceramics Division of ASUZAC Co., Ltd., which operates the Ceramics Design Lab, is a comprehensive manufacturer of fine ceramics that consistently processes ceramic raw materials from mixing, granulation, and molding to green processing (raw processing), firing, secondary processing, inspection and cleaning.

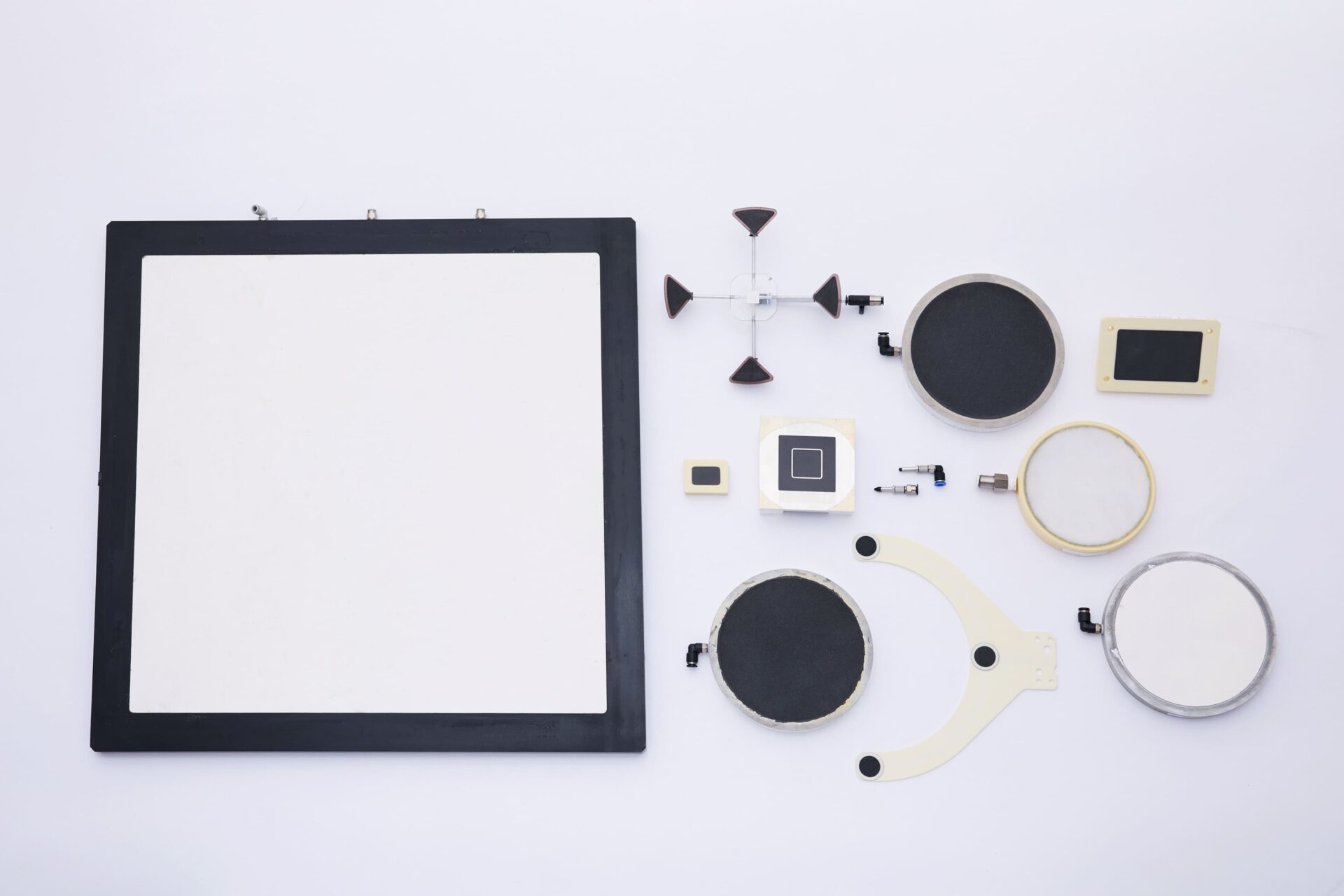

With the mission of “continuing to contribute to the development of advanced technology as a pioneer in fine ceramics,” we have been manufacturing a large number of ceramic products such as wafer Transfer End Effector / Handling Arm, trays, and substrates for semiconductor foundries, electronic device manufacturers, and equipment manufacturers for more than 40 years. We deliver ceramics products for various applications, shapes, and materials to our customers by making full use of the knowledge of ceramics materials, design and processing know-how cultivated in the process, as well as our equipment group and quality control system that can achieve high precision and quality from palm-sized to large and long items with a length of 4,000 mm.

For custom-made fine ceramic products, leave it to ASUZAC

What did you think? In this article, we have explained ceramics and fine ceramics in detail from the basics. In addition, we are disseminating various technical information, so please take a look. If you are considering custom-made fine ceramic products such as alumina, silicon carbide, and porous ceramics, please leave it to ASUZAC.

>>Click here for frequently asked questions

>>Click here for available Material / Size / Product

>>Click here for operating company

>>Click here for consultations and inquiries