Quotation request → Drawing confirmation → Study by us → Issue estimate → Order → Payment (prepaid) → Product production → Shipment → Delivery. If you do not have a drawing, you can also propose it. Please contact us for details.

For fine ceramic products such as Transfer End Effector / Handling Arm and Porous Chuck

made in Japan

<Telephone quotations/inquiries>

TEL+81-26-248-1626

Business hours: 9:00-17:00

(closed on Saturdays, Sundays and Holidays)

We are engaged in the trial manufacture and processing of various ceramics parts, including Alumina, SiC (silicon carbide), Porous ceramics, Zirconia, thermal insulation ceramics, and conductive ceramics, from the development of materials.

Particles are generated in the chamber and adhere to the wafer.

We are looking for a vacuum chuck to be used in a high-temperature environment. I'm worried about anti-chemicals and heat resistance with resin and metal.

We are considering the production of high purity alumina parts with purity of 99,99% or more, but the materials are not available.

Integrated support from developing not only Alumina and SiC but also porous ceramics and special ceramics with excellent heat resistance and electrical conductivity!

We have a proven track record of production of various industries, applications, and shapes such as wafer transfer End Effector / Handling Arm, vacuum chucks, large boards, and firing setters!

We offer proposals for VA / VE to customers that are possible only because they are familiar with the characteristics of ceramic materials and the problems unique to the semiconductors and electronics industries!

If you are in a hurry, please call us!

Business hours: 9:00-17:00 (closed on Saturdays, Sundays and Holidays)

Ceramics refer to natural inorganic substances such as ceramics, glass, and cement, which are produced by baking and solidifying them. Fine ceramics are manufactured using purified artificial raw materials such as Alumina, Zirconia, and silicon nitride to maximize their specific functions (high hardness, abrasion resistance, insulation, heat resistance, corrosion resistance, conductivity, heat transfer, etc.) (Advanced Technical Ceramics). They have steadily expanded their application range and market scale by taking advantage of their characteristics. They are used as components and components in various industrial fields such as information electronics, automobiles, energy, and the environment.

We will deepen our relationship with our customers, accurately grasp their needs, and proceed with product development based on development schedules tailored to our customers' roadmaps from a medium-to long-term perspective.

v1-1.jpg)

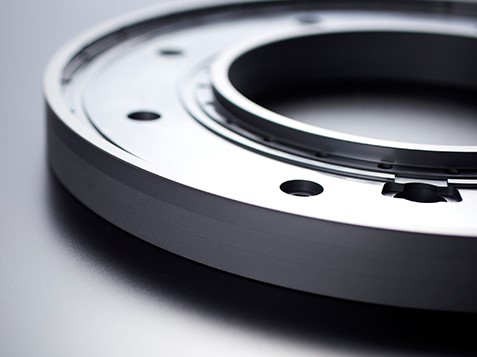

Wafer tray made of Alumina for dry etching (through hole type)

Industry: Semiconductor

Material: High Purity Alumina

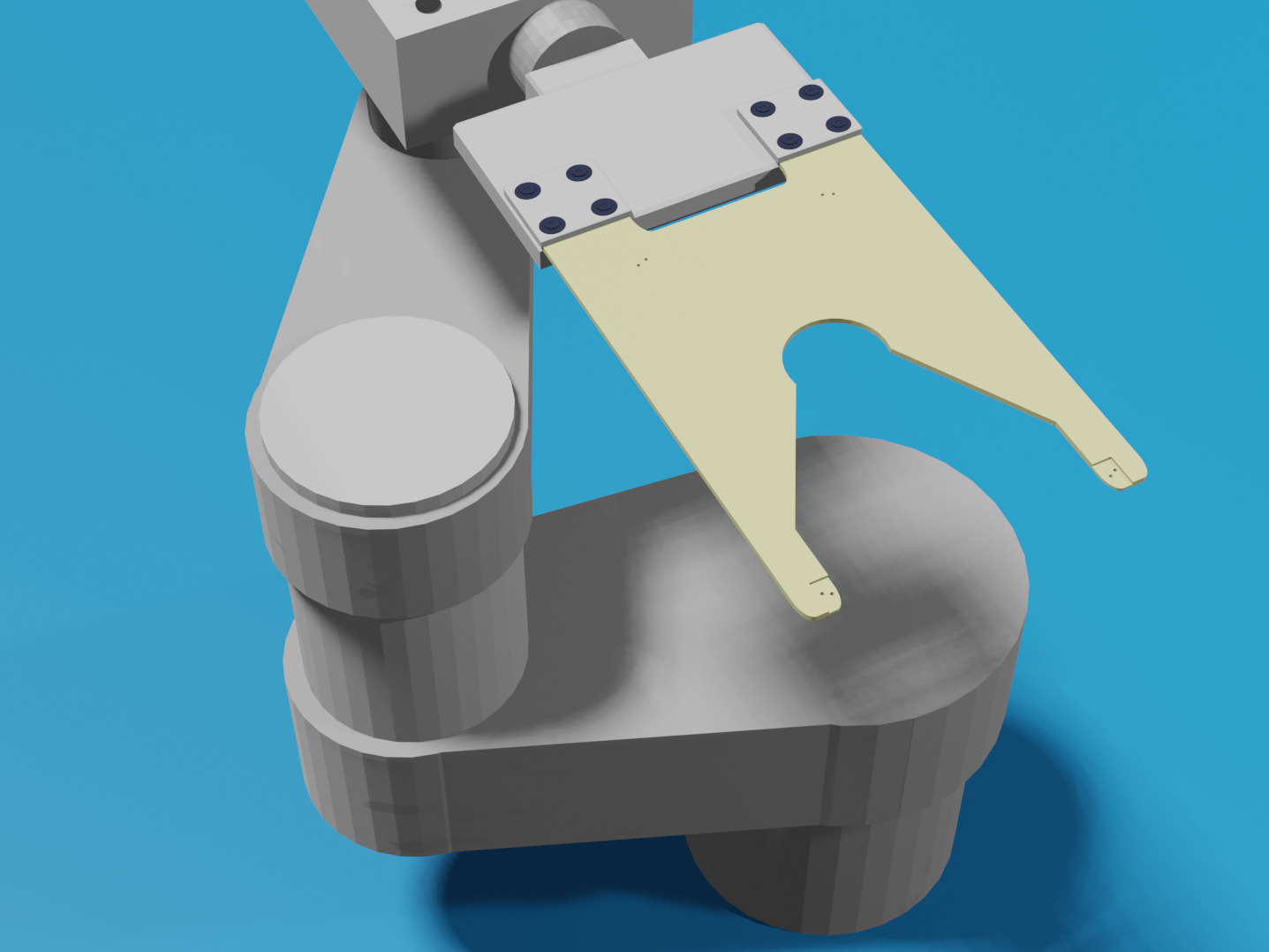

Transfer End Effector / Handling Arm for robots for cleaning equipment

Industry: Robots ・ Equipment

Material: High Purity Alumina

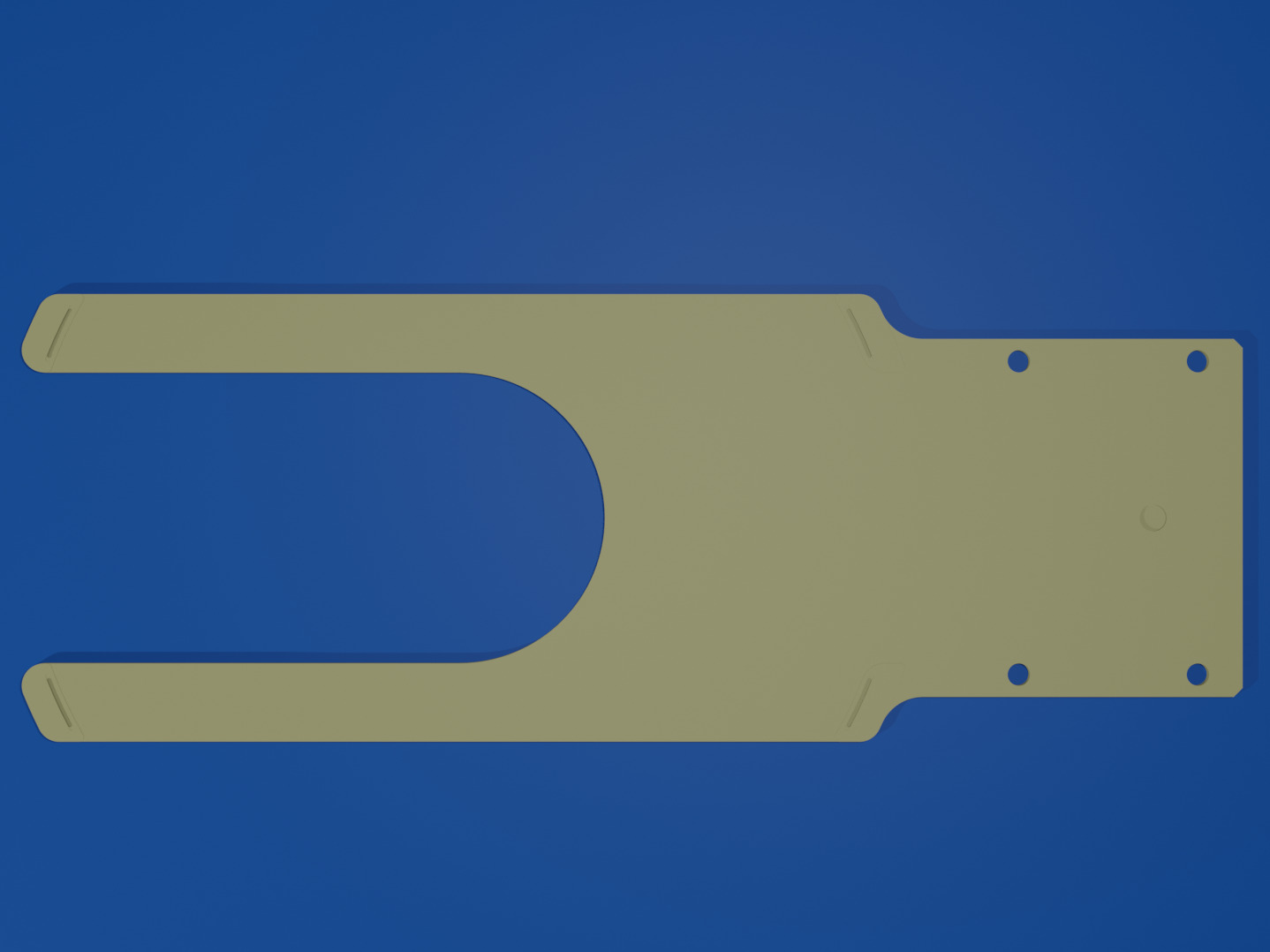

Robot Transfer End Effector / Handling Arm for 8-inch Wafer Suction (PeriZac®)

Industry: Semiconductor,Optical equipment

Material: High Purity Alumina

Porous filter

Industry: Chemistry・Material

Material: Porous Ceramics

v1.jpg)

Thrust pin made of conductive ceramics (Thrust needle)

Industry: Semiconductor

Material: Conductive Ceramics

SiC Crucible

Industry: Ceramics firing jig,Industrial machinery,University・Research institute

Material: SiC(Silicon Carbide)

Integrated support from developing not only Alumina and SiC but also porous ceramics and special ceramics with excellent heat resistance and electrical conductivity!

We have a proven track record of production of various industries, applications, and shapes such as wafer transfer End Effector / Handling Arm, vacuum chucks, large boards, and firing setters!

We offer proposals for VA / VE to customers that are possible only because they are familiar with the characteristics of ceramic materials and the problems unique to the semiconductors and electronics industries!

If you are in a hurry, please call us!

Business hours: 9:00-17:00 (closed on Saturdays, Sundays and Holidays)

Quotation request → Drawing confirmation → Study by us → Issue estimate → Order → Payment (prepaid) → Product production → Shipment → Delivery. If you do not have a drawing, you can also propose it. Please contact us for details.

For alumina, the length 4000 mm, breadth 70 mm, and thickness 50 mm are guidelines. For SiC, 500 mm×500 mm×5 mm is a rough guide. For other materials, 300 mm×300 mm×10 mm is a rough guide. Even within the above size, it may not be possible to manufacture depending on the product shape. Contact us for more information.

We will propose wave and V-shaped setters. The V-shaped setter can be manufactured with external 140 mm×100 mm, thickness 8 mm, V-shaped angle 112.6°, and pitch 120 mm(P12×10) The reaction between the setter and the work piece can be minimized by placing the work piece on the wave-shaped or V-shaped setter and firing.

| Company Name | ASUZAC CORPORATION |

|---|---|

| Division name | Fine Ceramics Division |

| Division established | October, 1981 |

| Address | Headquarters: 981 Oaza Nakayama, Takayama-mura, Kamitakai-gun, Nagano 382-8508, Japan |

| factory | Takayama factory |

| Sales Offices | Headquarters, Tokyo, Osaka and Kyushu |

| TEL | +81-26-248-1626 |

| FAX | +81-26-251-2160 |

| fcerainf@asuzac.co.jp | |

| Description of Businesses | Development, production, processing, and sales of ceramics |

Frequently Asked Questions

Common questions from

the Ceramics Design Lab

Available Material / Size / Product

Please see our wide range of

services

Equipment owned

Our processing and

inspection facilities

Company profile

Ceramics Design Lab is

operated by Asuzac Co., Ltd.

The quotation and inquiries are available by the telephone /FAX or the mail .

FAX. +81-26-251-2160