| Product Name | UniZac-Pair 8-inch Porous embedded hand with sensor groove |

|---|---|

| Classification | Porous embedded End Effector |

| Use | For wafer transport (atmospheric use) |

| Material | Adsorption part:Porous ceramics,Body:Alumina and SiC(Silicon Carbide) |

| Feature |

・Grooved for sensor mounting ・Thin warped wafers can be adsorbed ・Hard to adhere adsorption marks on wafers |

| Size | 215 × 125 × 3.5 mm |

Features Of This Product

Features of "UniZac-Pair 8-inch Porous embedded hand with sensor groove"

-

・There is a groove at the base of the End Effector for attaching a sensor.

・Thin warped wafers can be handled.

・Hard to stick suction marks on wafers.

Shape of "UniZac-Pair 8-inch Porous embedded hand with sensor groove"

-

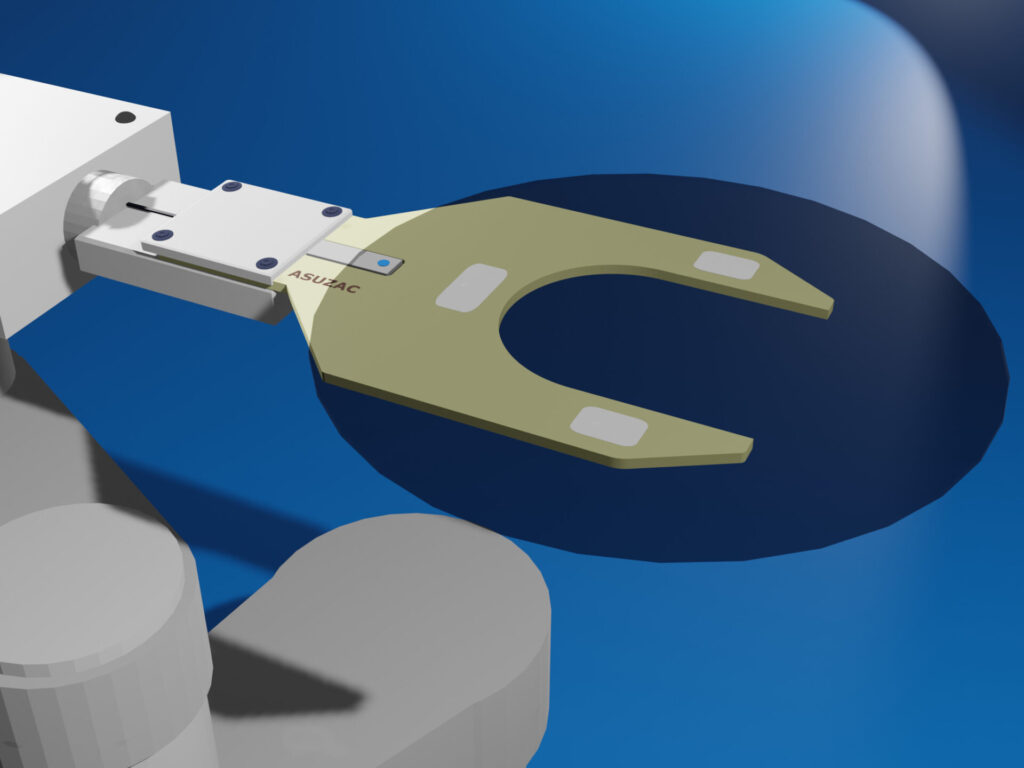

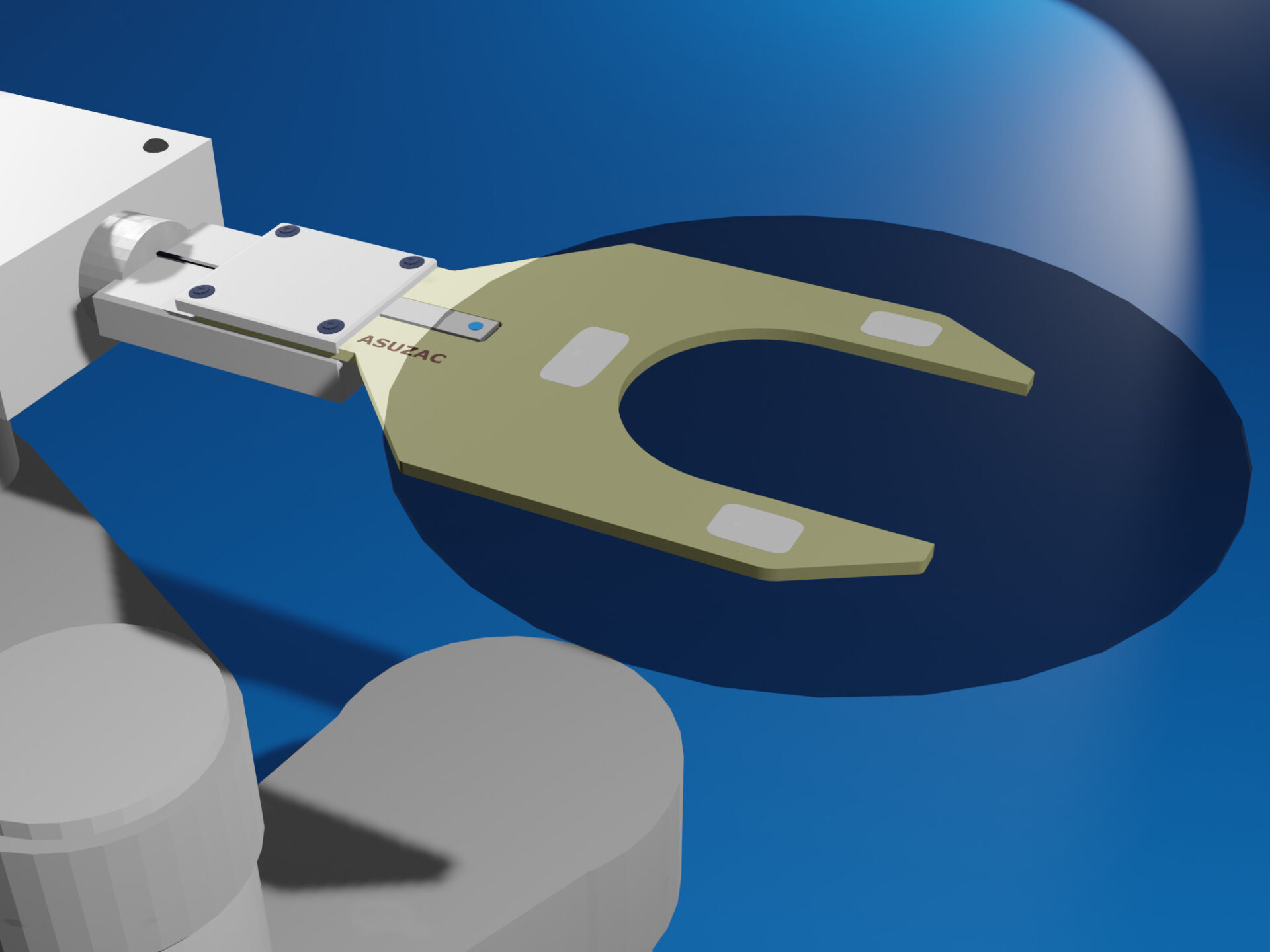

Figure 1 shows the geometry of an 8-inch porous embedded End Effector with a sensor groove.

A sensor groove about 12 wide, 80 long, and 1.7 deep is machined in the center of the root of the End Effector. -

Figure 2 shows an A-A cross section of an 8-inch porous embedded End Effector with sensor grooves (see Figure 1). The specification is to bond the porous ceramic AZP60 to the main body alumina with adhesive.

Examples and achievements of "UniZac-Pair 8-inch Porous embedded hand with sensor groove"

Frequently Asked Questions on "UniZac-Pair 8-inch Porous embedded hand with sensor groove"

-

Yes, we use adhesives. It is used to bond the body and the porous material. The available temperature range varies depending on the type of adhesive. Please contact us for details.Contact us from here→

-

Possible. We will design according to your requirements.

Please contact us for details.Contact us from here→ -

Production is possible.We can produce wafers for 4″, 5″, 6″, and 12″ wafers. Please contact us for details.Contact us from here→

-1024x768.jpg)

-1024x768.jpg)

.jpg)

The wafer adsorption part is made of porous ceramics AZP60.

A sensor groove is machined into the root of the End Effector.

A sensor can be attached to the sensor groove to detect misalignment or tilt of the wafer.

Porous ceramics AZP60 is embedded in the alumina of the main body using an adhesive.

Thin and warped wafers can be adsorbed.

This End Effector is characterized by the fact that it is difficult to leave suction marks on the wafer.