For fine ceramic products such as Transfer End Effector / Handling Arm and Porous Chuck

made in Japan

<Telephone quotations/inquiries>

TEL+81-26-248-1626

Business hours: 9:00-17:00

(closed on Saturdays, Sundays and Holidays)

EQUIPMENT OWNED

Here we introduce our main processing and inspection and measurement facilities.

Pick-up equipment

-

Large-scale green processing machine

Green processing (raw processing) is performed on ceramic materials after CIP molding, taking into account the shrinkage caused by firing.

-

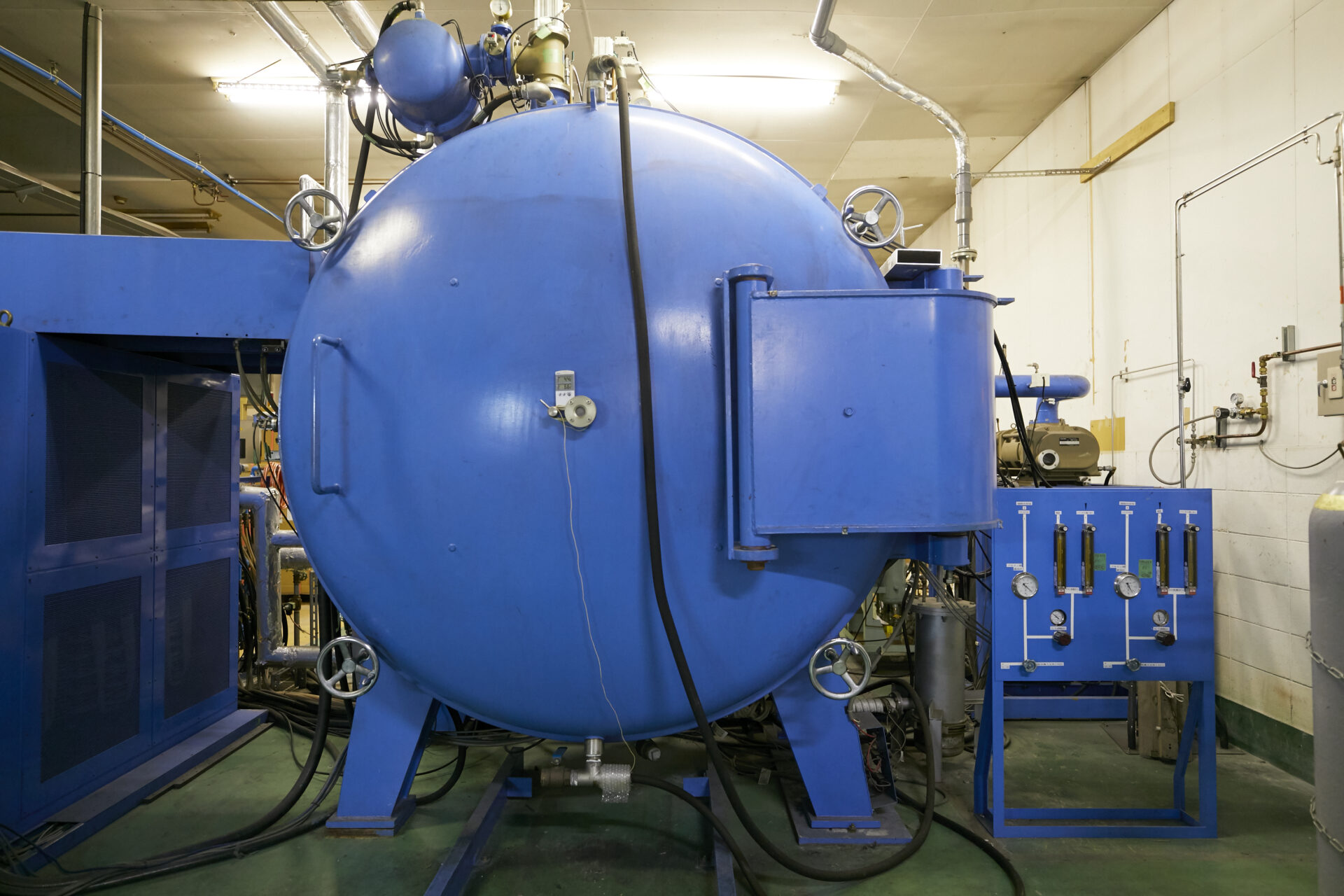

Vacuum firing furnace

This vacuum furnace fires green-processed ceramic compacts.

After firing, the exterior and dimensions are checked and color check (immersion flaw detection) is performed. -

Electric furnace

Like a vacuum furnace, it becomes an electric furnace that fires work pieces after green processing.

We have multiple kilns, such as vacuum furnaces, electric furnaces and gas furnaces, so that we can respond flexibly from trial production to mass production of medium lots. -

Large gate machining center

This is a machining center that processes fired ceramics into final product dimensions.

Diamond tools are used for machining. -

Vertical machining center

This vertical machining center is suitable for high-efficiency machining of difficult-to-machine materials.

Used in secondary processing after firing.

This is the model with the largest number of units in our company. -

Surface grinding machine

High-hardness materials such as ceramics are basically processed by grinding.

We have many surface grinders, rotary grinders, and cylindrical grinders with long stages. -

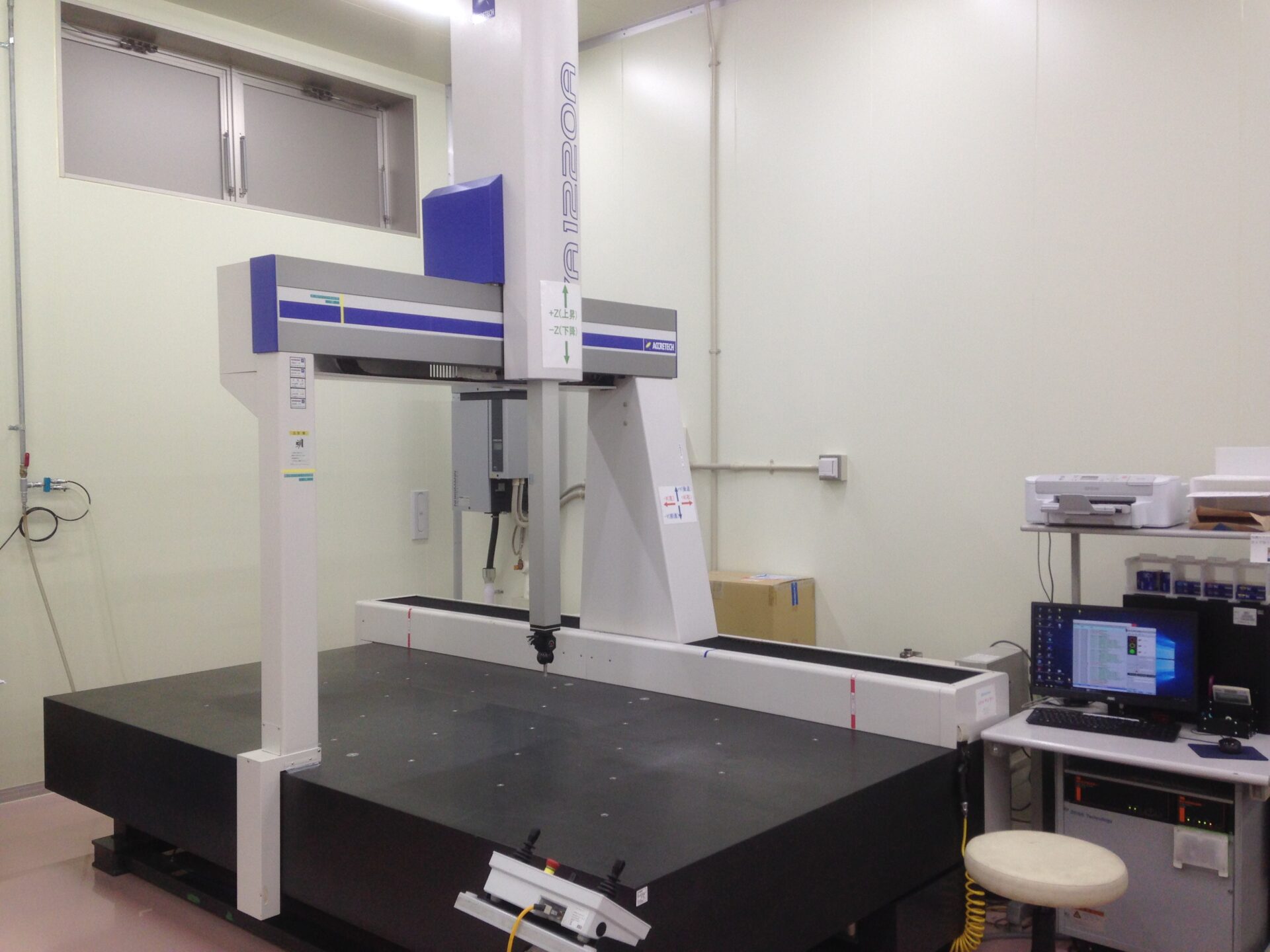

3-D measuring machine

Inspection is performed using a caliper, pin gauge, or three-dimensional measuring instrument.

Also, a full-time inspector visually checks for chipping, chipping, cracks, and foreign matter. -

10-tank automatic cleaning system

This multi-layer automatic cleaning system is designed for semiconductors and electronic components where contamination by impurities or foreign matter is not permitted.

Products after cleaning are stored and shipped in a clean booth. -

Inductively Coupled Plasma-Mass Spectrometer (ICP-MS)

This equipment analyzes and evaluates trace elements required by the semiconductor industry.

The system is thoroughly managed in clean rooms to avoid extremely small amounts of contamination, enabling advanced analysis at several hundred ppm to sub-levels, such as cleaning qualities and post-product-use trace metal analysis.

-

Look for from the industry

-

Search from the product type

-

Look for materials

-

Examples of VA / VE

proposals for design developers -

PRODUCTS AND SERVICES

-

Latest technology column

-

CONTENT

-

Frequently Asked Questions

Common questions from

the Ceramics Design Lab -

Available Material / Size / Product

Please see our wide range of

services -

Equipment owned

Our processing and

inspection facilities -

Company profile

Ceramics Design Lab is

operated by Asuzac Co., Ltd.

CONTACT

The quotation and inquiries are available by the telephone /FAX or the mail .

FAX. +81-26-251-2160

.jpg)

.jpg)