| Product Name | LeviZac® Floating standard End Effector (Bernoulli method) |

|---|---|

| Classification | Floating standard End Effector (Bernoulli method) |

| Use | For wafer transport (atmospheric use) |

| Material | 高純度アルミナ |

| Feature |

Capable of handling warped wafers Capable of handling thin wafers Achieves non-contact except for the outer guide |

| Size |

■For wafer size 300mm 350 × 220 × 2.5 mm ■For wafer size 200mm 272 × 100 × 2.5 mm |

Features Of This Product

Features of "LeviZac® Floating standard End Effector (Bernoulli method)"

-

・Thin wafers can be handled.

・Able to transfer warped wafers.

・Non-contact is realized except for the guide on the outer circumference

・Particle generation due to contact with the guide is suppressed.

・Cavity integration technology improves durability.

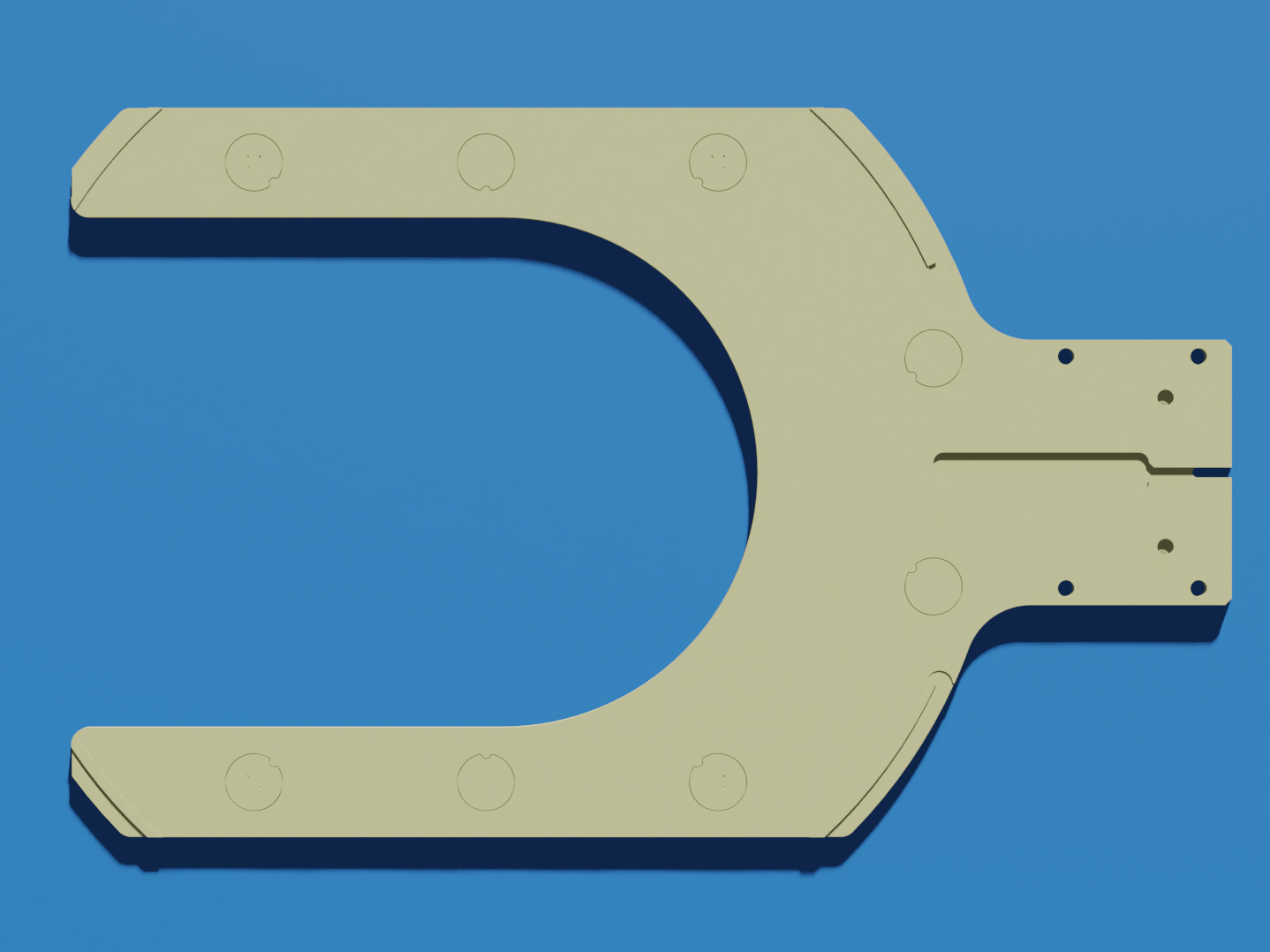

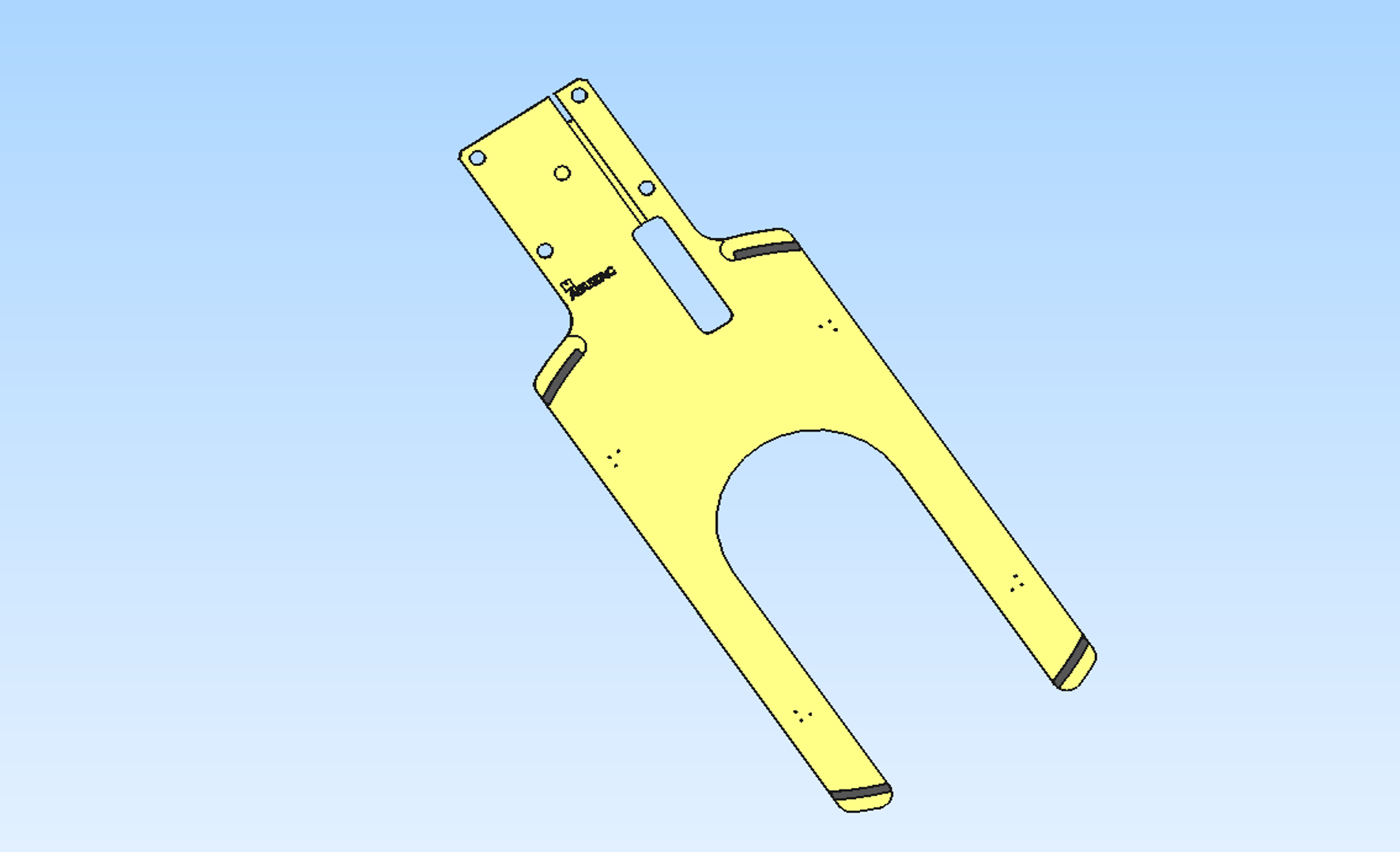

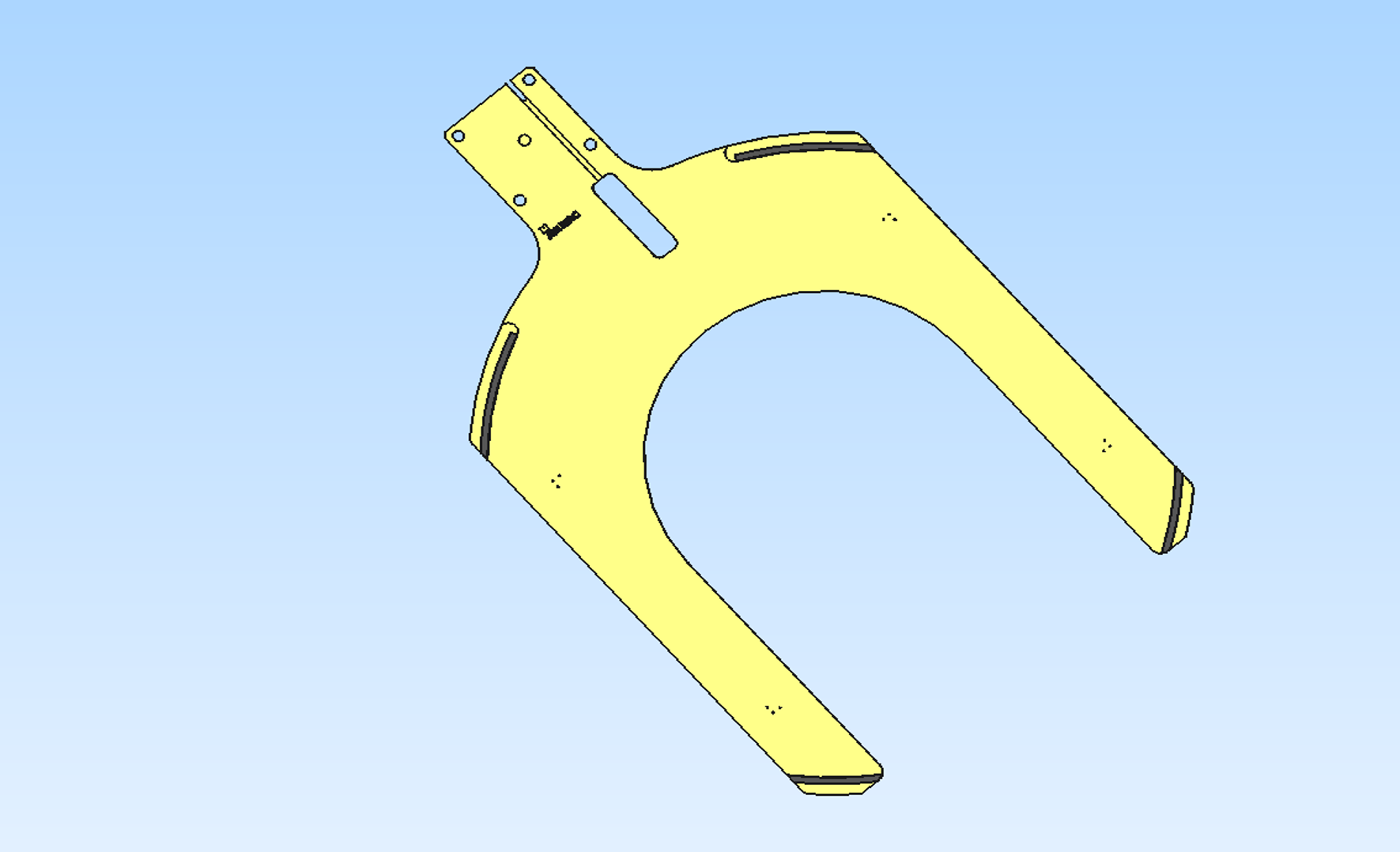

Shape of "LeviZac® Floating standard End Effector (Bernoulli method)"

-

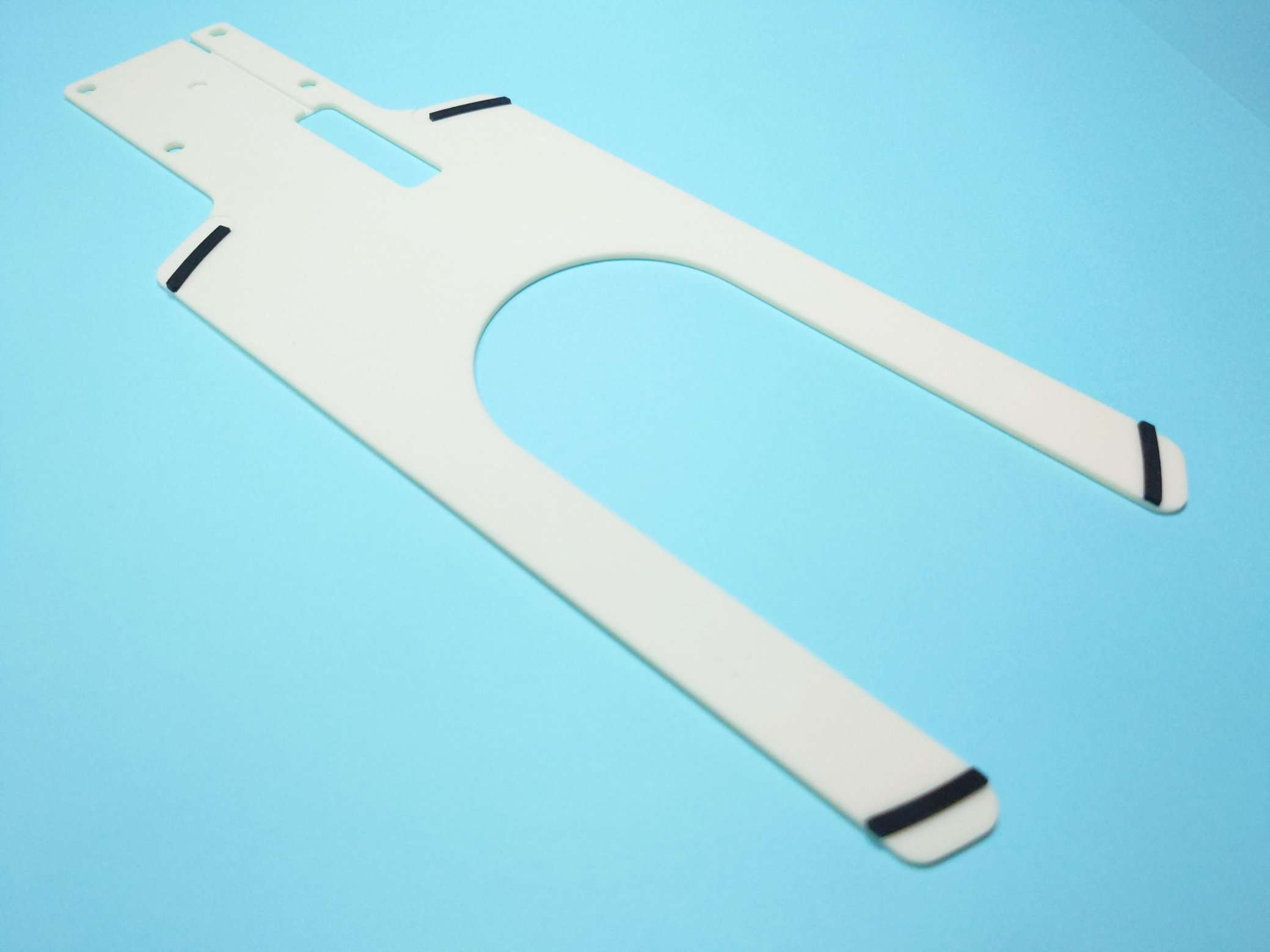

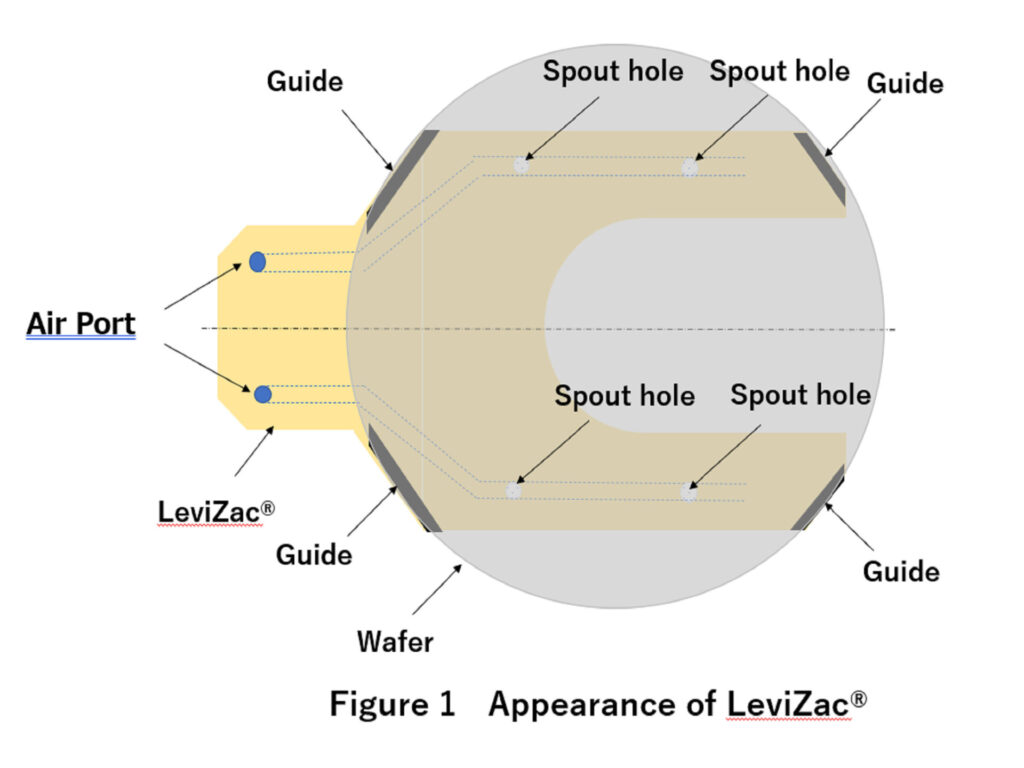

Figure 1 shows the external shape of the LeviZac®.It has four jet holes and guides.

-

Figure 2 is a cross-sectional view of LeviZac®.The wafer can be held at 3 mm around the wafer periphery.

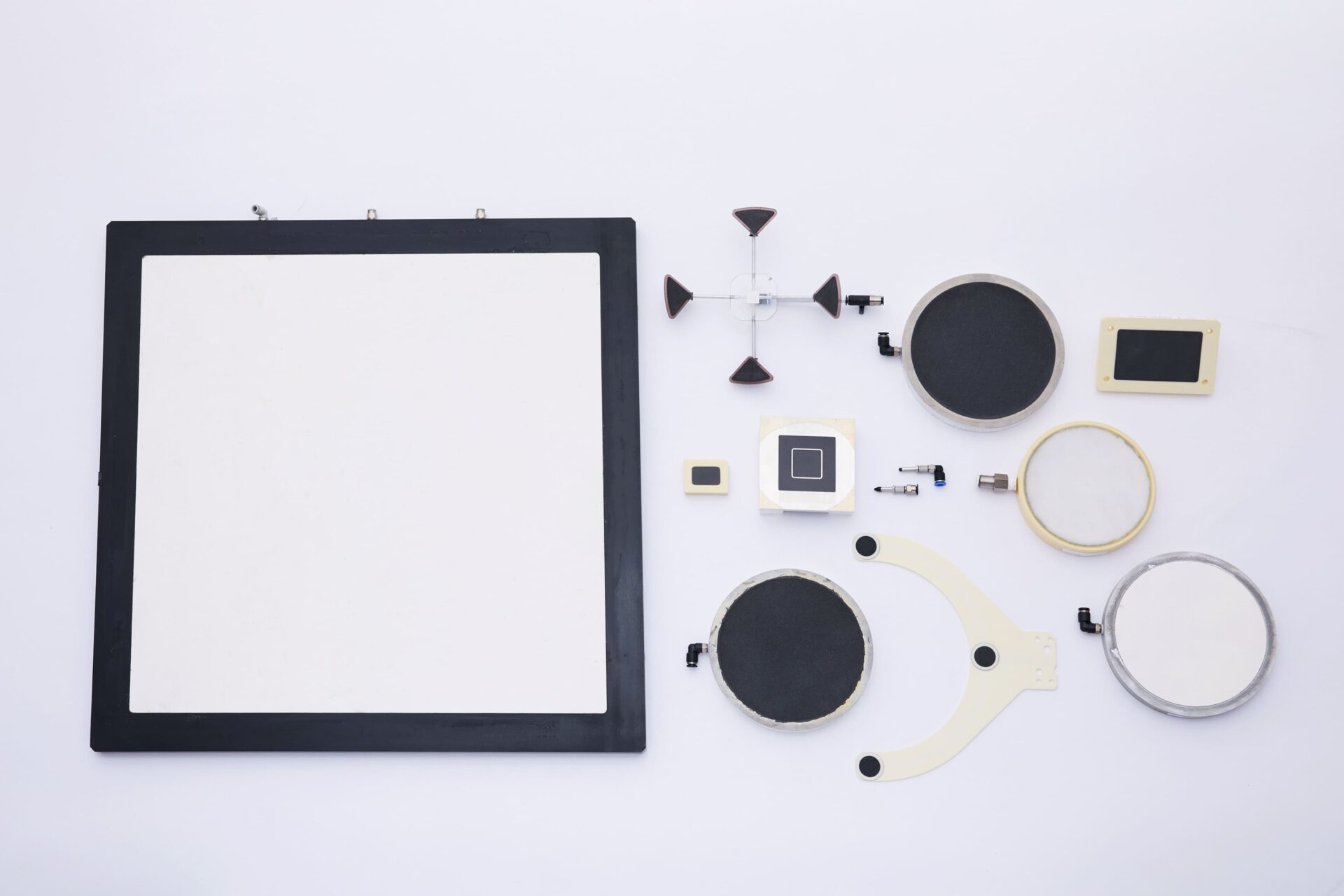

Examples and achievements of "LeviZac® Floating standard End Effector (Bernoulli method)"

Download Drawings of"LeviZac® Floating standard End Effector (Bernoulli method)"

LeviZac8-inch

(LeviZac8-inch)

- Warped wafer

- Thin wafer

- Flotation type

- Bernoulli equation

- Heat resistance

- For Atmospheric

- Spouting hole

- Guide

- Integrated cavity

Capable of holding wafers within 3mm of wafer circumference

LeviZac12-inch

(LeviZac12-inch)

- Warped wafer

- Thin wafer

- Flotation type

- Bernoulli equation

- Heat resistance

- For Atmospheric

- Spouting hole

- Guide

- Integrated cavity

Capable of holding wafers within 3mm of wafer circumference

Video of "LeviZac® Floating standard End Effector (Bernoulli method)"

-

Bernoulli Hand (LeviZac) 8-inch wafer holding video in water

This is a video of an 8-inch Bernoulli End Effector / Handling Arm (LeviZac) holding a wafer in water. The wafer is held by spewing water from four spouting holes. The wafer is held by four guides with an outer circumference of about 3 mm. It can be used underwater. -

LeviZac 12-inch transport video

This is a 12-inch Bernoulli End Effector / Handling Arm (LeviZac) wafer transfer video. The wafer is held by blowing air from four blowout holes. The wafer is held by four guides with an outer circumference of about 3 mm. The LeviZac can be rotated to hold the wafer. Wafers can be transported while sucking them from above.

Frequently Asked Questions on "LeviZac® Floating standard End Effector (Bernoulli method)"

-

Since the heat resistance temperature of the guide is 100°C, it is difficult to use the guide at higher temperatures.For use in high temperature environments, we will propose a shape in which the guide material is alumina.Please contact us for details.

-

Fabrication is possible: Y-shaped LeviZacs can be fabricated for 4inch, 5inch, and 6inch wafers.The LeviZac for 4-inch wafers can hold 5- to 8-inch wafers.I-shape LeviZac is also available.

-

LeviZac® holds the workpiece in a horizontal position with four guiding points.The top of the workpiece is attracted from above, held in place, and then transferred.

-

The LeviZac® can hold wafers by pouring water or liquid into an empty channel and ejecting it through a jet hole. For more information, please see this video. >>LeviZacunderwater wafer reention video

-1024x768.jpg)

サイズ調整-1024x768.jpg)